Method for regulating and controlling particle size of porous silicon nanoparticles

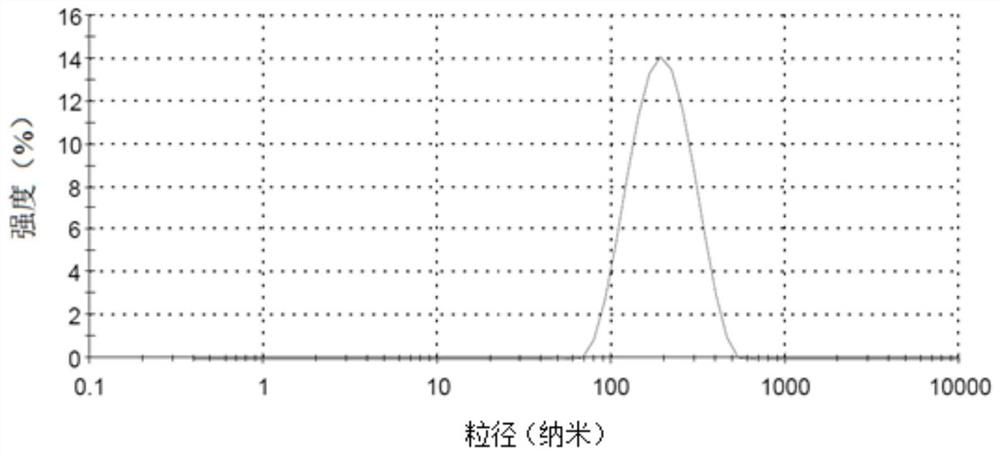

A nanoparticle and porous silicon technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of large particle size, poor dispersion, wide particle size distribution of porous silicon, etc., to achieve uniform particle distribution, average The effect of small particle size and high application rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for regulating the particle size of porous silicon nanoparticles, comprising the steps of:

[0037] (1) Pretreatment of silicon wafers: first cut the silicon wafers into rectangles of about 1.5×1.5cm, prepare a solution with a volume ratio of concentrated sulfuric acid (98%):hydrogen peroxide=3:1, and put the cut rectangular silicon wafers into In the solution, immerse and heat for 15 minutes under the condition of 80°C water bath, the purpose is to remove the organic pollutants on the surface of the silicon wafer. Afterwards, rinse the silicon wafer repeatedly with a large amount of deionized water until the residual liquid after the last rinse is neutral, and store the silicon wafer in deionized water for later use;

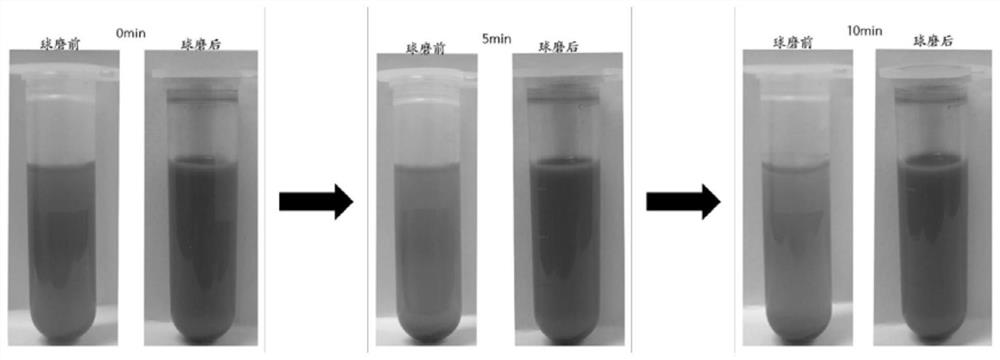

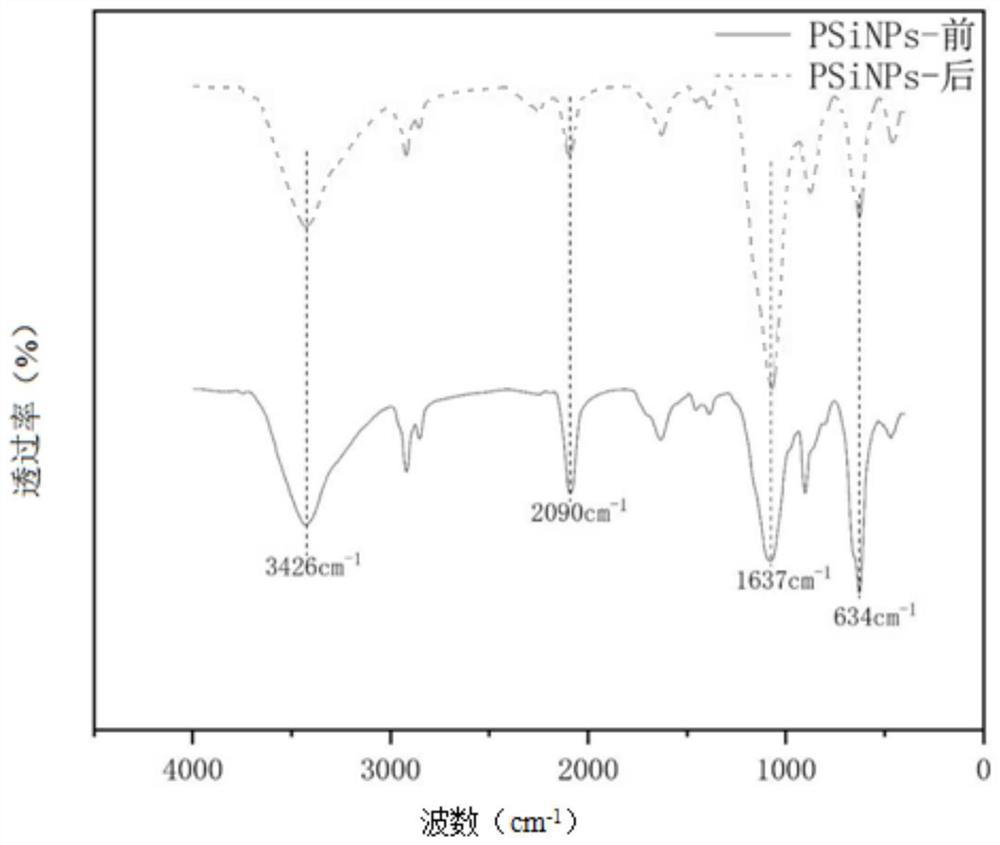

[0038] (2) Preparation of porous silicon nanoparticles: the preparation of porous silicon nanoparticles is carried out by electrochemical etching; the silicon wafer is taken out from deionized water, and the silicon wafer is dried with high-puri...

Embodiment 2

[0041] A method for regulating the particle size of porous silicon nanoparticles, comprising the steps of:

[0042] (1) Pretreatment of silicon wafers: first cut the silicon wafers into rectangles of about 1.5×1.5cm, prepare a solution with a volume ratio of concentrated sulfuric acid (98%):hydrogen peroxide=2.5:1, and put the cut rectangular silicon wafers into In the solution, immerse and heat for 10 minutes in a water bath at 75°C, in order to remove organic pollutants on the surface of the silicon wafer. Afterwards, rinse the silicon wafer repeatedly with a large amount of deionized water until the residual liquid after the last rinse is neutral, and store the silicon wafer in deionized water for later use;

[0043] (2) Preparation of porous silicon nanoparticles: the preparation of porous silicon nanoparticles is carried out by electrochemical etching; the silicon wafer is taken out from deionized water, and the silicon wafer is dried with high-purity nitrogen gas, and th...

Embodiment 3

[0046] A method for regulating the particle size of porous silicon nanoparticles, comprising the steps of:

[0047] (1) Pretreatment of silicon wafers: first cut the silicon wafers into rectangles of about 1.5×1.5 cm, prepare a solution with a volume ratio of concentrated sulfuric acid (98%):hydrogen peroxide=3.5:1, and put the cut rectangular silicon wafers into In the solution, immerse and heat for 20 minutes under the condition of 85°C water bath, the purpose is to remove the organic pollutants on the surface of the silicon wafer. Afterwards, rinse the silicon wafer repeatedly with a large amount of deionized water until the residual liquid after the last rinse is neutral, and store the silicon wafer in deionized water for later use;

[0048] (2) Preparation of porous silicon nanoparticles: the preparation of porous silicon nanoparticles is carried out by electrochemical etching; the silicon wafer is taken out from deionized water, and the silicon wafer is dried with high-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com