Foaming material composition, foaming material and preparation method thereof

A foaming material and composition technology, applied in the field of foaming materials, can solve the problems of poor cell uniformity and poor stiffness, and achieve the effect of uniform cells, good stiffness, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

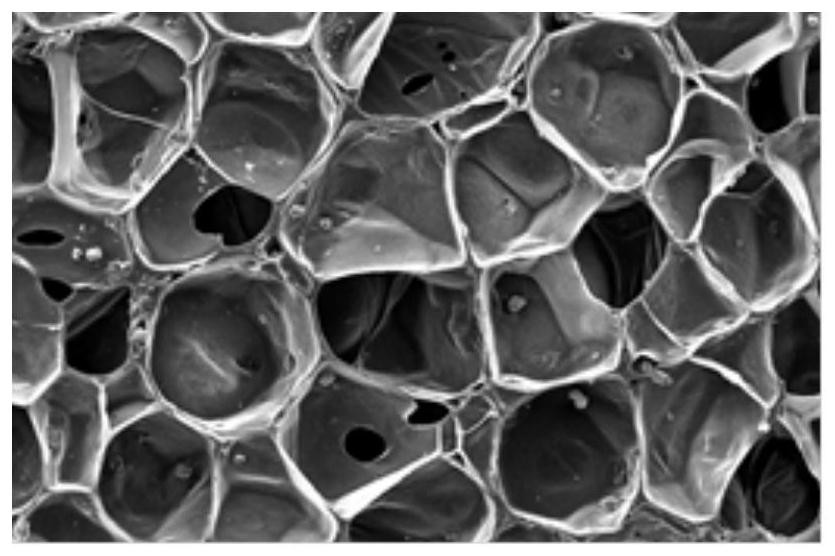

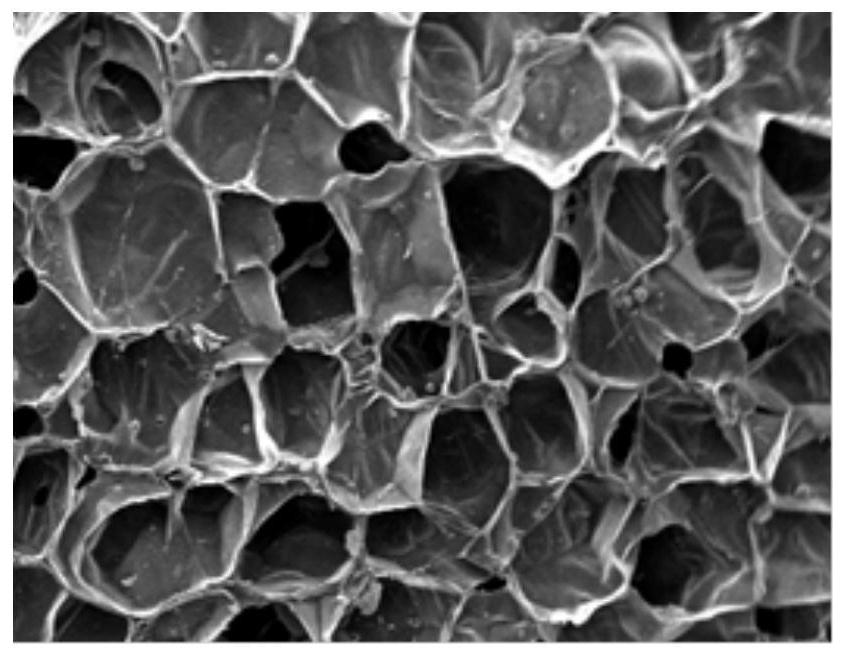

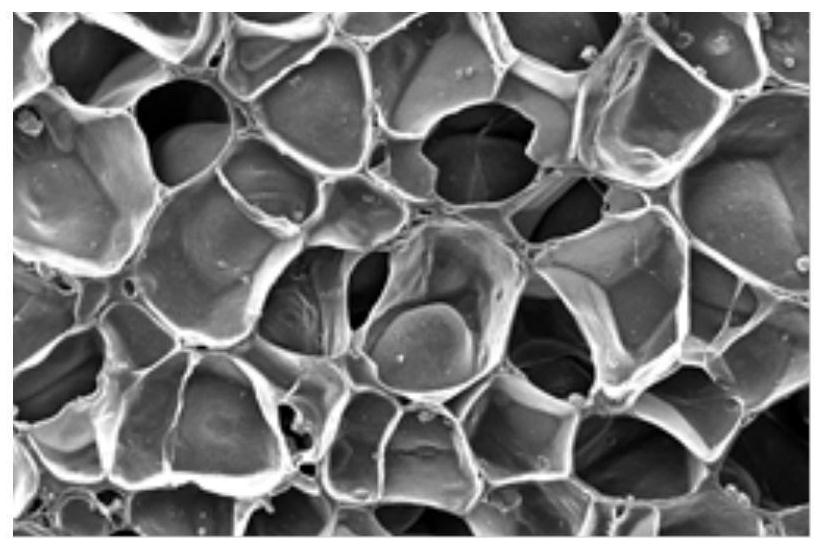

Image

Examples

Embodiment 1

[0086] The initial temperature of the internal mixer is set at 100±3°C, the speed is 77rpm, and the rubber composition is mixed; the blend obtained by mixing is then subjected to a secondary vulcanization process on a hydraulic plate vulcanizer to obtain vulcanized rubber B1, wherein , the conditions of one-stage vulcanization include: the vulcanization temperature is 160°C, the vulcanization pressure is 15MPa, and the vulcanization time is 3min; 11min.

[0087] The composition of the rubber composition is listed in Table 1.

[0088] The vulcanized rubber B1 was tested and evaluated, and the results are shown in Table 2.

[0089] The remaining examples are carried out with reference to the process of Example 1, the specific process parameter conditions are as shown in Table 1, and the results are as shown in Table 2.

[0090] Table 1

[0091]

[0092]

[0093] Table 1 (continued 1)

[0094]

[0095]

[0096] Table 1 (continued 2)

[0097]

[0098]

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com