Blast furnace hearth and bottom erosion discrimination method based on combination of newly installed and old thermocouples

A discrimination method and thermocouple technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of thermocouple failure, failure to monitor the residual thickness of blast furnace hearth bottom refractory materials in time, etc., and achieve the effect of improving longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

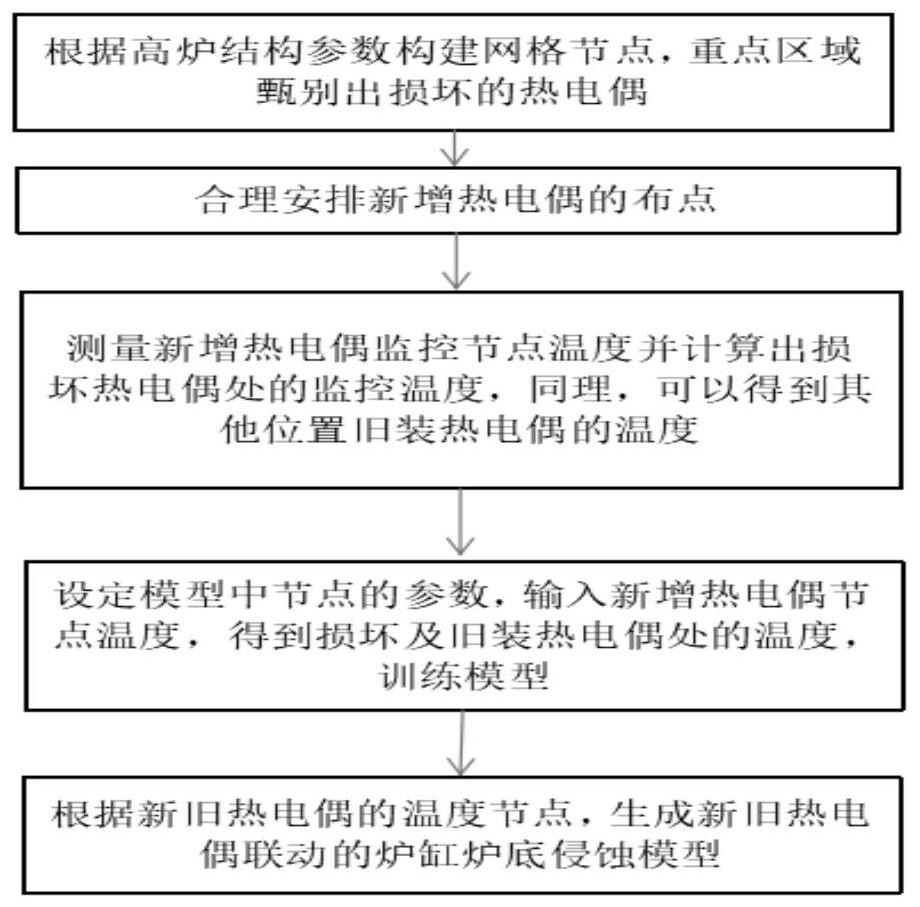

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for discriminating corrosion of the blast furnace hearth bottom based on the combination of newly installed and old thermocouples. The blast furnace body 1 is provided with an old thermocouple 4 (or the original thermocouple), and the old thermocouple 4 is connected to the data processing unit. 3 Sending signals, using the data processing unit 3 to directly record and process the internal temperature of the blast furnace. The data processing unit 3 is an intelligent terminal, such as a computer, and has a data display module such as an LED display. During the entire production process of the blast furnace, some thermocouples will fail due to various emergencies. Even if a new thermocouple 2 is installed in the damaged area, both the new thermocouple 2 and the old thermocouple 4 will send monitoring documents to the data processing unit 3, It can solve the problem of failure of some thermocouples. Preferably, the newly installed thermoco...

Embodiment 2

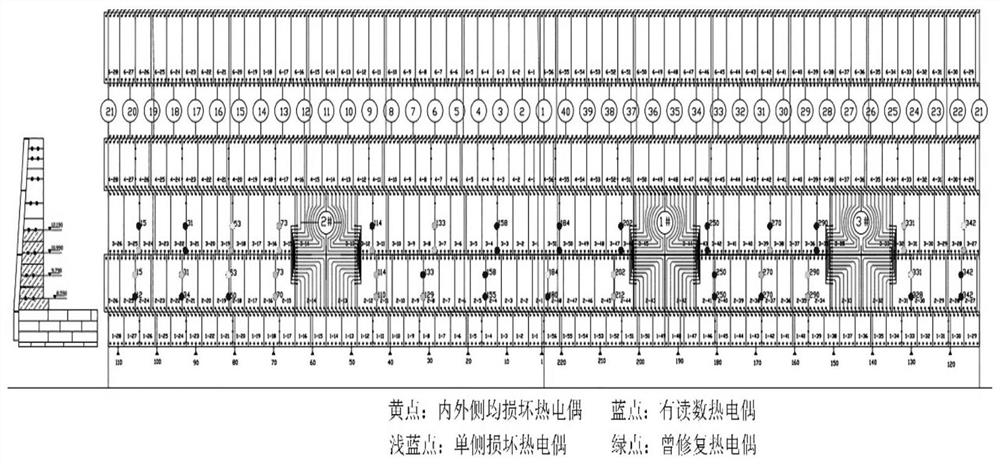

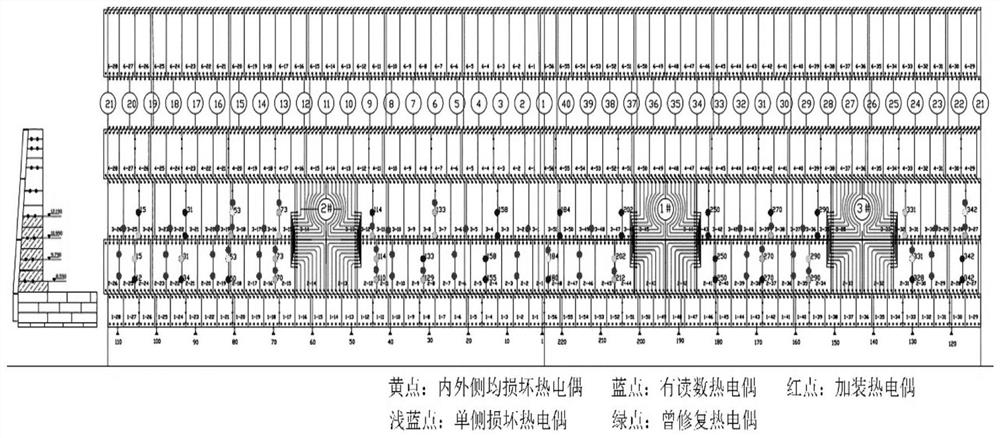

[0028] On the basis of Example 1, this example provides a method for discriminating corrosion of the hearth bottom of a blast furnace based on the combination of newly installed and old thermocouples. The blast furnace body 1 is 5800m 3 For blast furnaces, considering the two-dimensional heat transfer on the side wall of the hearth, the layout of newly installed thermocouples 2 should be reasonably arranged at the same elevation and different depths and at the same depth and different elevations, and the furnace bottom part should be replaced reasonably according to the specific damaged parts of the thermocouples. The operation method is as follows:

[0029] Step 1: Select key four-layer thermocouples covering areas with severe hearth erosion, such as the elephant foot area and the area near the iron mouth, for key investigations, respectively at elevations of 8.59m, 9.79m, 10.99m, and 12.19m.

[0030] The second step: Through comprehensive analysis and statistics of the damag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com