Parallel disassembly line setting method combining priority relation matrix

A priority relationship matrix and linear programming technology, applied in the direction of manufacturing computing systems, instruments, complex mathematical operations, etc., can solve problems such as local optimal optimization capabilities, inability to obtain optimal solutions, and inability to form production line operations to achieve good practical results The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

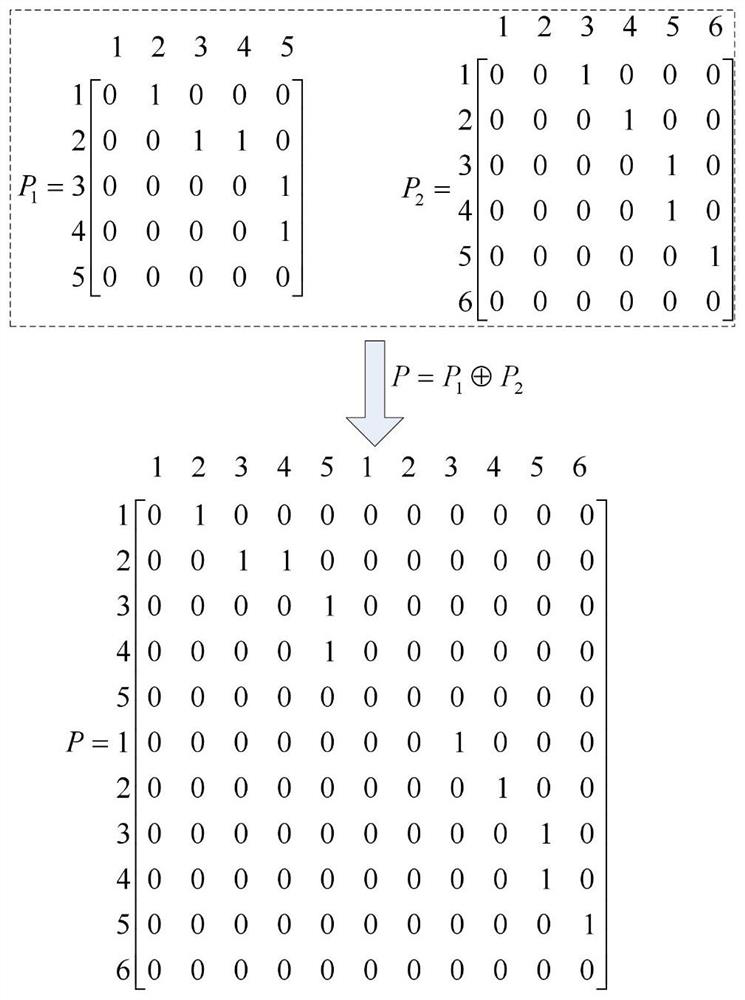

Method used

Image

Examples

Embodiment 1

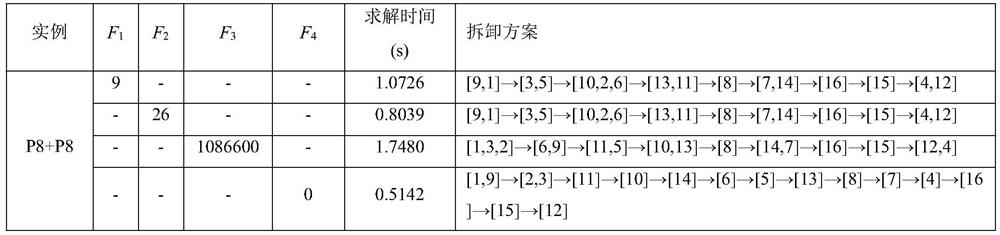

[0055] In order to highlight that this embodiment has a good effect on the small-scale parallel dismantling line balance problem and the large-scale parallel dismantling line balance problem, the following simulation experiments are carried out:

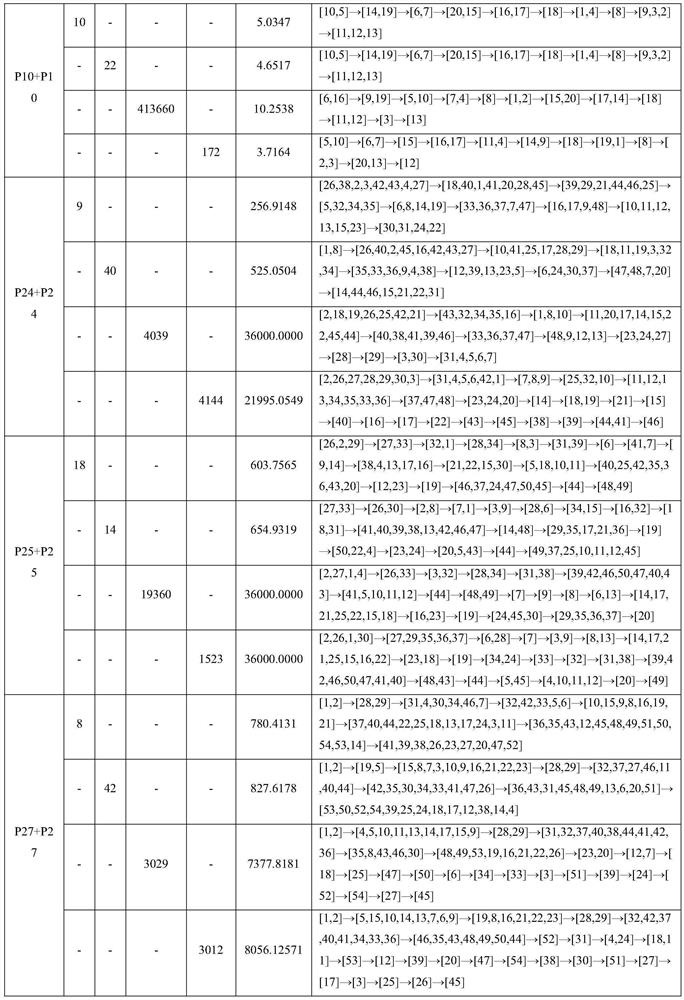

[0056] Based on the data in the document "Atabu search algorithm for balancing a sequence-dependent disassembly line", the parallel disassembly simulation results of similar end-of-life products of P8+P8 are given; based on the document "2-opt heuristic for the disassembly line balancing problem" Based on the data of P10+P10, the parallel disassembly simulation results of similar end-of-life products are given; based on the data in the document "A Pareto firefly algorithm for multi-objective disassembly line balancing problems with hazarddevaluation", the similar life of P24+P24 is given. The simulation results of parallel disassembly of the final product; based on the data in the document "Ant colony optimization for sequence-depende...

Embodiment 2

[0065] For most disassembly lines, the problem they face is the mixed disassembly of different end-of-life products, that is, the same workstation needs to disassemble different parts of two different products to be disassembled, but for this type of disassembly line arrangement , there is currently no better way.

[0066] In this example, the original data of P8 is based on the document "A tabu search algorithm for balancing a sequence-dependent disassembly line", the original data of P10 is based on the document "2-opt heuristic for the disassembly line balancing problem", and the original data of P24 is based on the document " AParetofirefly algorithm for multi-objective disassembly line balancing problems with hazard evaluation", the original data of P25 is based on the document "Ant colony optimization for sequence-dependent disassembly line balancing problem", the original data of P27 is based on the document "Modeling and Optimization of Partial Balancing Disassembly-Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com