Arc extinguish chamber and circuit breaker

An arc extinguishing chamber and arc extinguishing technology, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve problems such as insufficient arc extinguishing gas pressure, limited closing and breaking performance, etc., to improve breaking performance, Withstand transient recovery voltage and good arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

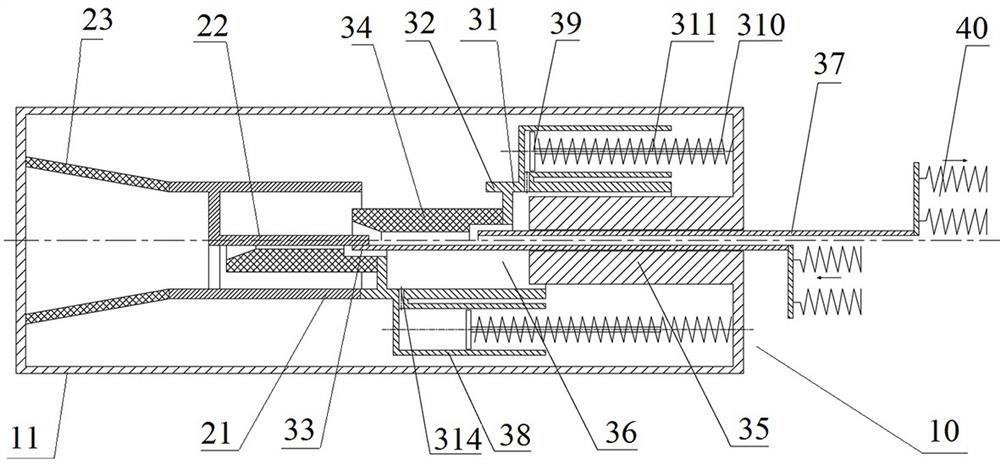

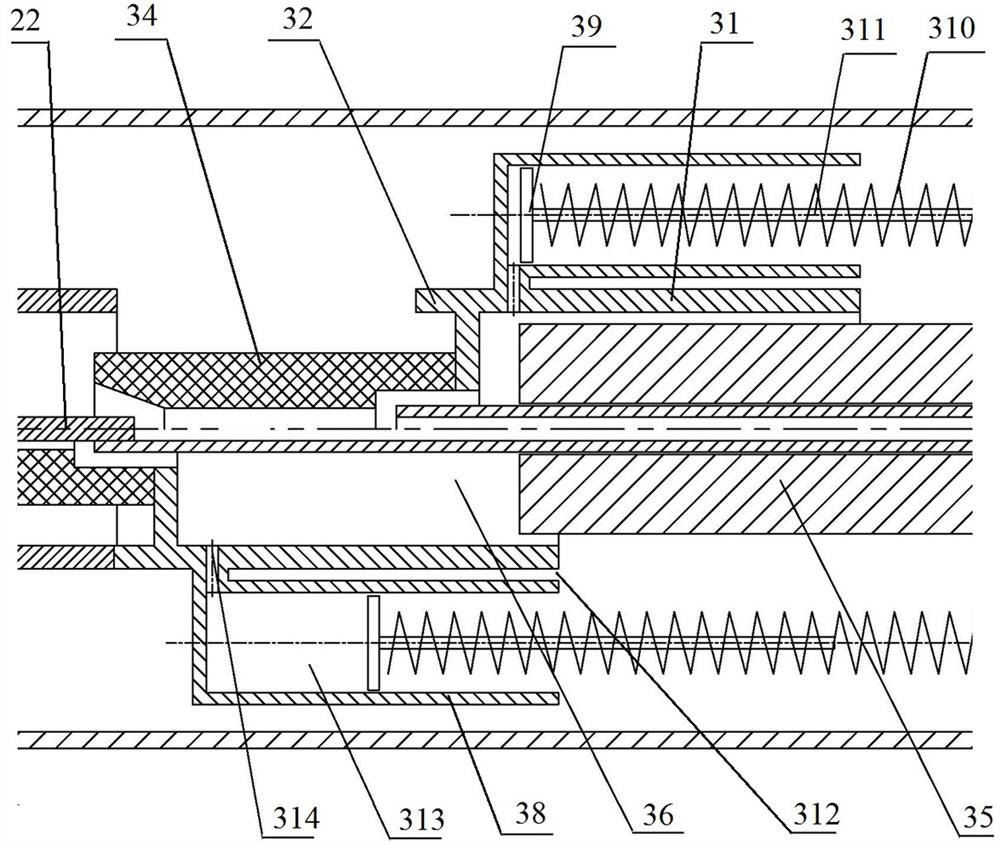

[0086] Such as figure 1 As shown, the circuit breaker includes an arc extinguishing chamber 10 and an operating mechanism 40, and the operating mechanism 40 is used to drive the arc extinguishing chamber 10 to close and open. The operating mechanism 40 can adopt the operating mechanism in the prior art, and the specific principle will not be described in detail here.

[0087] The arc extinguishing chamber 10 includes a housing 11, which is used to form a closed air chamber for filling the arc extinguishing gas; the front end of the housing 11 is provided with a static end assembly, which includes a static main contact 21 and a static arc The contact 22 , the static main contact 21 and the static arc contact 22 are fixed on the static end contact seat 23 . The rear end of the housing 11 is provided with a movable end assembly, which includes a pneumatic cylinder 31 , a movable main contact 32 , a movable arc contact 33 and a nozzle 34 . The rear end of the housing 11 is fixed...

Embodiment 2

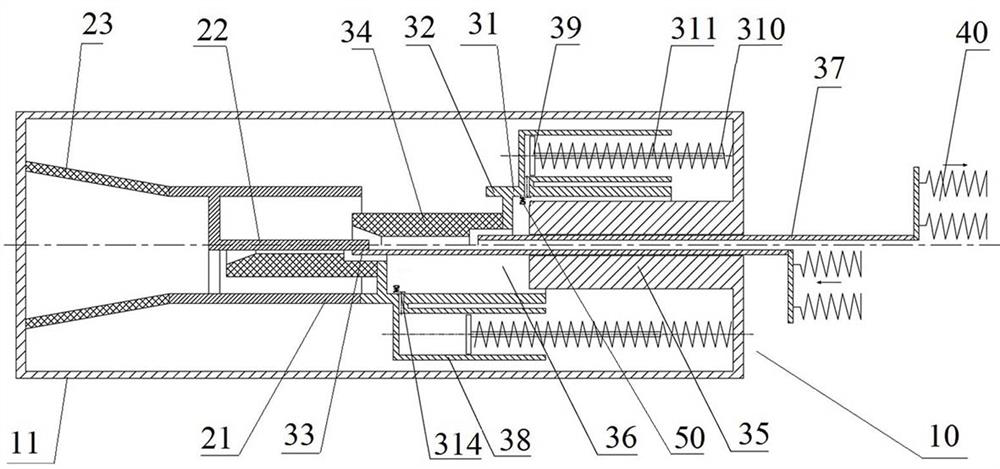

[0093] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, a gas check valve 50 is provided at the orifice of the communication hole 314 located at one end of the compression chamber 36, and the gas check valve 50 includes a guide The column 51 , the valve plate 52 and the return spring 53 are used to realize one-way communication from the air supply chamber 313 to the air compression chamber 36 . The gas check valve 50 can prevent the gas in the compression cylinder 31 from being poured back into the gas supply cylinder 38 due to the spring in the cylinder 38 being too soft during the opening process, which is beneficial to reduce the design requirements for the stiffness coefficient of the buffer spring 310 .

[0094] When the circuit breaker is working, the pre-opening gas supply chamber 313 and the compression chamber 36 are isolated from each other under the action of the gas check valve 50. After t...

Embodiment 3

[0096] Such as Figure 5 and Figure 6 As shown, the difference between this embodiment and Embodiment 2 is that in this embodiment, the static arc contact 22 is guided along the front and rear directions; a double The dynamic linkage structure and the double-action linkage structure make the arc extinguishing chamber 10 form a double-acting arc extinguishing chamber 10, which is used to drive the static arc contact 22 to move when the moving end assembly moves. The double-action linkage structure adopts the form of connecting rod transmission, including a linkage rod 60. One end of the linkage rod 60 close to the moving end assembly is hinged on the nozzle 34 of the moving end assembly, and the other end is hinged on the middle connecting rod 62; the middle connecting rod 62 The middle part is hinged on the housing 11, and the driven rod 63 is hinged between the end away from the linkage rod 60 and the static arc contact 22. When the nozzle 34 moves forward, the static arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com