Integrated electrical device for motor controller

A motor controller and integrated electrical technology, which is applied in the direction of electrical components, electrical solid devices, electrical equipment structural parts, etc. Complicated process and other issues, to achieve the effect of small footprint, good filtering effect, easy disassembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

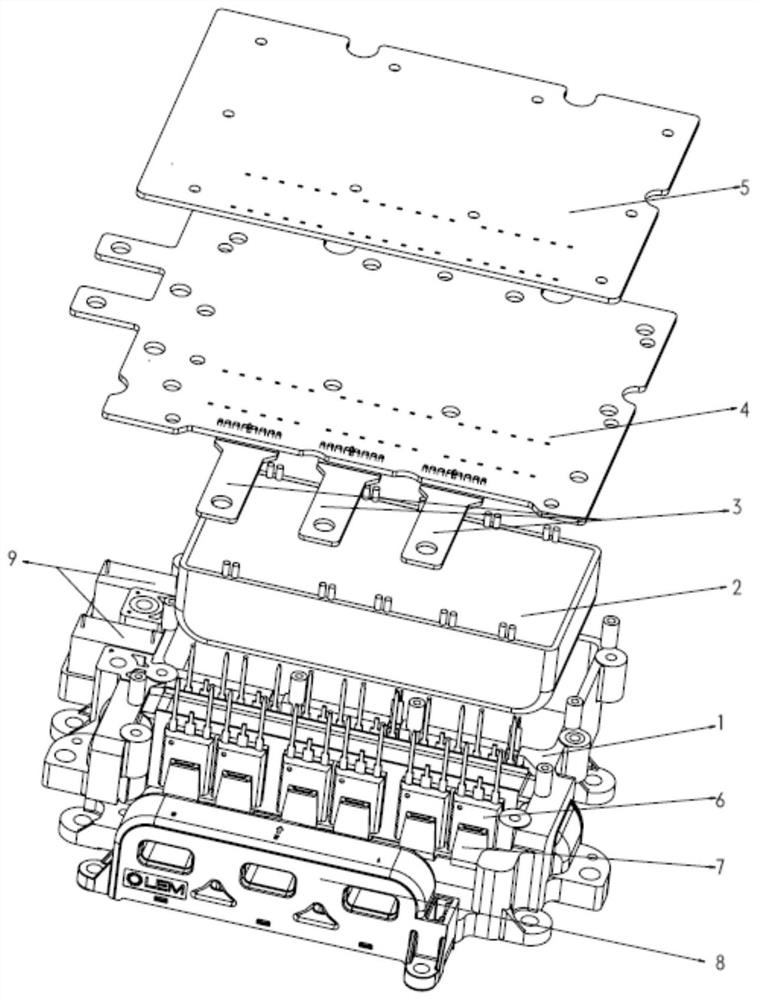

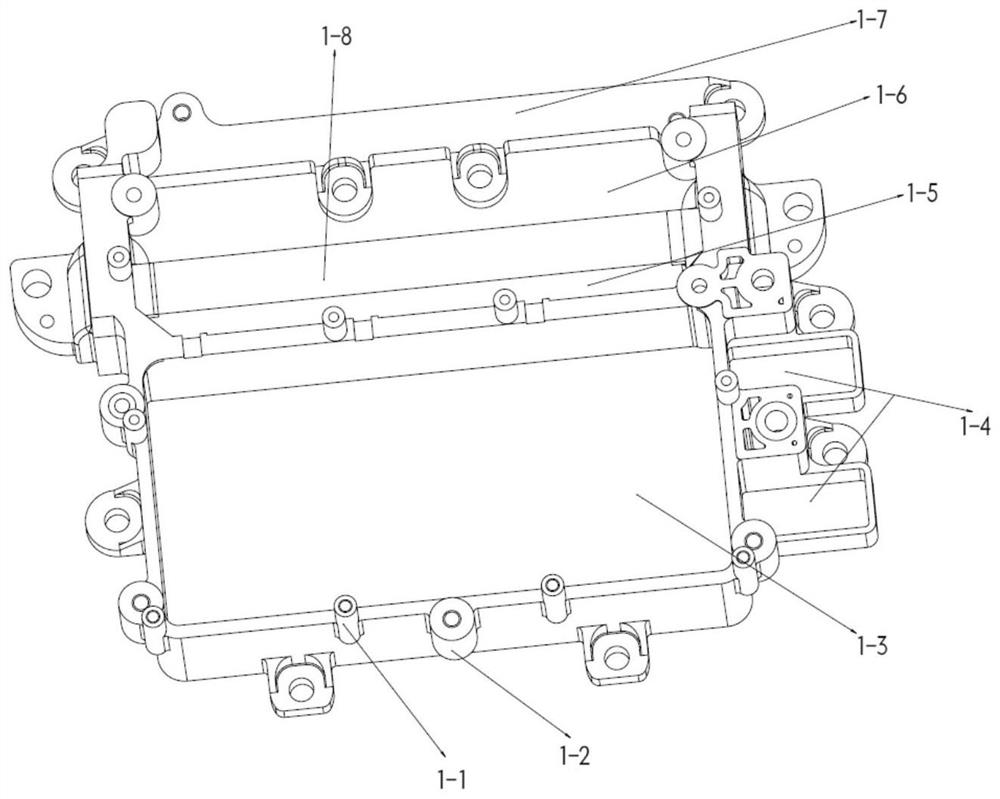

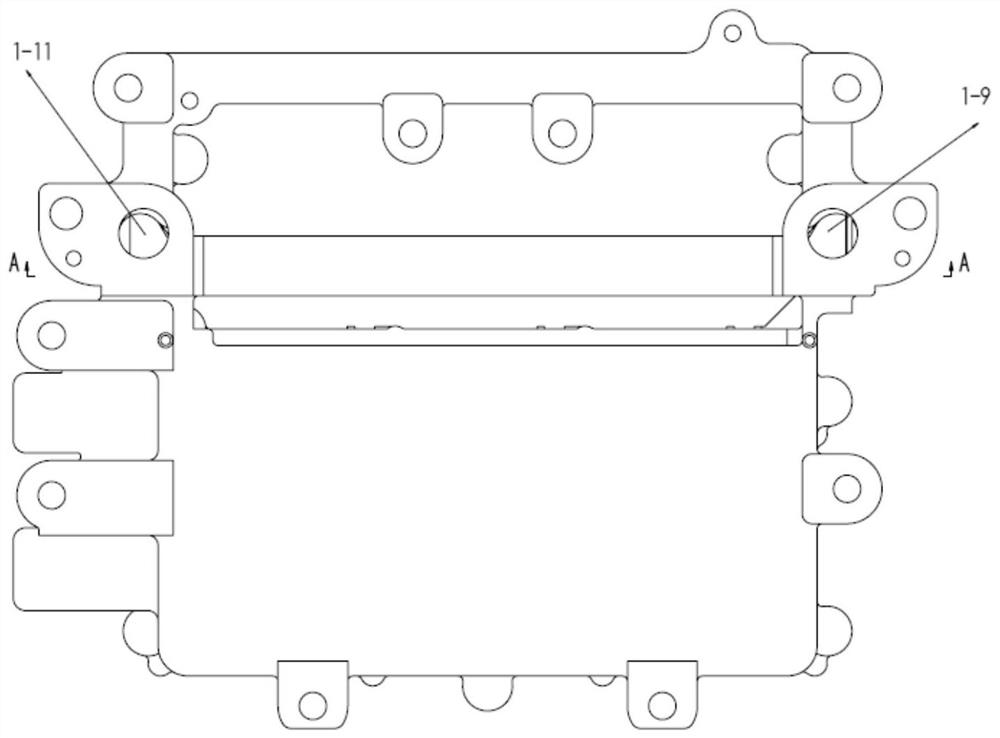

[0033] Such as figure 1 As shown, this application proposes an integrated electrical device for a motor controller, which includes a bracket 1, a film capacitor 2, a three-phase copper bar 3, a drive board 4, a control board 5, an IGBT6, a clamping spring 7, and a Hall sensor 8 and Y capacitor 9. Film capacitor 2 , three-phase copper bar 3 , drive board 4 , control board 5 , IGBT 6 , clamping spring 7 , Hall sensor 8 and Y capacitor 9 are all assembled on the bracket 1 . Among them, the film capacitor 2 and the Y capacitor 9 are potted in the groove above the bracket 1 with potting glue, and the IGBT6 is attached to both sides of the heat dissipation channel 1-8 of the bracket 2 respectively, and is clamped and fixed by the clamping spring 7, and the Hall The sensor 8 is fixed on the support 1 , and the driving board 4 is arranged on the film capacitor 2 , the Y capacitor 8 and the IGBT 6 and fixed on the support 1 .

[0034] The input end and the output end of the film capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com