Vehicle composite material control arm and forming method thereof

A composite material and molding method technology, applied in the field of vehicle accessories, to achieve the effects of improving structural strength and anti-deformation performance, avoiding injection, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

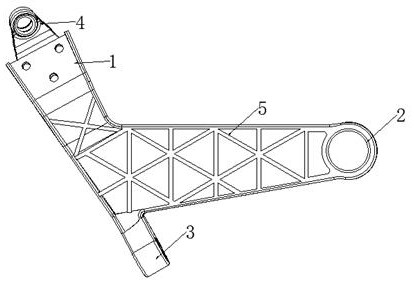

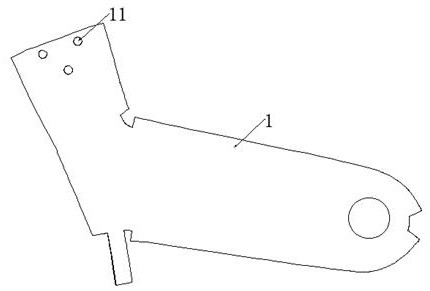

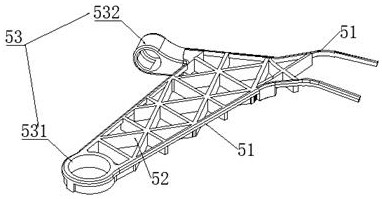

[0025] The invention discloses a vehicle composite material control arm which integrates metal inserts, thermoplastic carbon fiber composite materials and plastic materials. panel. The shape of control arm body 1, structure are identical with existing control arm body, comprise three ends, as figure 1 As shown, metal inserts are respectively embedded in the two ends, that is, the first bush 2 and the second bush 3. Specifically, the first bush 2 is placed horizontally, and the second bush 3 is vertically placed. Placed vertically, the third end of the control arm body 1 has three connection holes 11 for riveting or screwing the ball head 4, that is, the ball head 4 is installed after the control arm body 1 is formed. A plastic part 5 is also injection-molded on the control arm body 1 .

[0026] Specifically, the plastic part 5 includes an outer frame 51, a reinforcing mesh 52 and a bush connector 53; wherein, the outer frame 51 is located on the edge of the control arm body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com