One-step forming excavation drill bit for shallow square foundation pit

A technology for foundation pits and drill bits, which is applied in the direction of drill bits, earthwork drilling, drill pipes, etc., which can solve problems such as lack and achieve the effect of ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

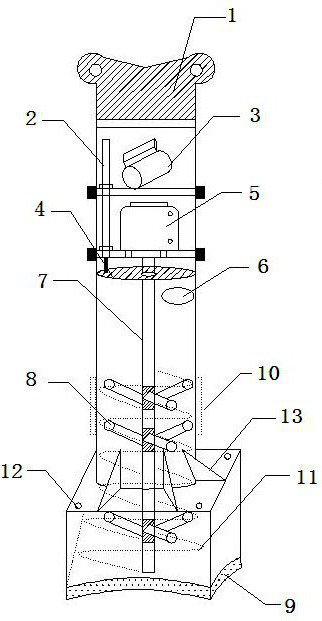

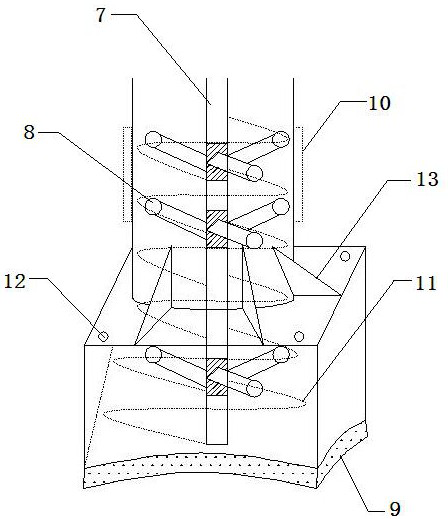

[0030] see figure 1 , figure 2 , image 3 It can be seen that the excavation drill for shallow layer square foundation pit of the present invention comprises a drill body, a steel pipe is provided outside the drill body, and a drill rod 7 is arranged in the steel pipe; the drill body is provided with a connection mechanism and a vibration mechanism from top to bottom. , a hydraulic device and a drill mechanism, the drill mechanism includes a steel pipe, the lower end of the steel pipe is connected to the box body, a reinforcement structure is provided around the connection position between the box body and the steel pipe, a cavity is provided inside the box body and the steel pipe, and a drill rod is arranged in the cavity 7. Auger blade 11, drill pipe support 8, the lower end of the box body is in the shape of an arc, and an alloy blade 9 is installed at the arc shape, the four corners of the box are provided with air holes 12, and the lower end of the air hole 12 is provid...

specific Embodiment 2

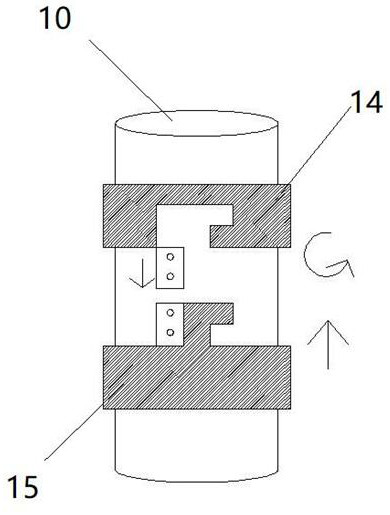

[0032] see image 3 It can be seen that the shallow square foundation pit of the present invention is excavated at one time, the quick connector 10 is provided with an upper connecting portion 14 and a lower connecting portion 15, the corresponding position of the upper connecting portion 14 is provided with a connecting groove, and the corresponding position of the lower connecting portion 15 is A connection protrusion is provided, the inner cavity of the quick connector 10 has the same diameter as the main body of the upper structure, and the lower structure has the same diameter as the bottom of the box body.

specific Embodiment 3

[0034] see figure 1 It can be seen that the shallow square foundation pit of the device of the present invention is formed at one time and excavated the main body assembly of the drill bit:

[0035] Divided into three sections,

[0036] The upper large-diameter seamless steel pipe is welded to the excavator connecting mechanism and the lower end is flanged.

[0037] The vibrator base is set inside the middle section, and the oil cylinder communication hole is reserved. Both ends are flanged and locked with the screws of the upper and lower sections.

[0038] The lower part is equipped with hydraulic cylinder and hydraulic motor 4 bases, a bulldozing blade, and an observation port is reserved on the cylinder wall. Bottom is provided with drilling rod 7 tripod supports.

[0040] The upper end is provided with a universal quick connector 10, the inner cavity is conical, the upper part is consistent with the diameter of the main body of the device, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com