Visual sintering-free flat plate sand filling model device and method

A model device and sinter-free technology, which is applied in earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of poor model transparency, unfavorable observation, changes in pore structure and wettability, and epoxy resin is not environmentally friendly. , to achieve the effect of maintaining rock consistency, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

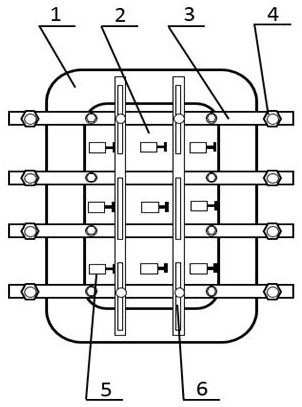

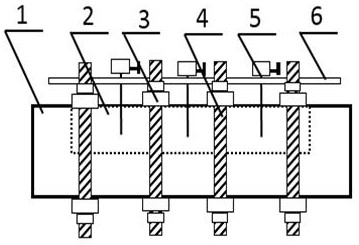

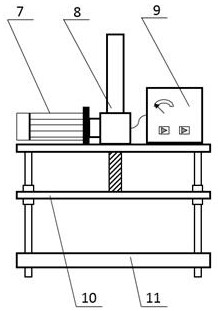

[0043] Such as Figure 1 to Figure 4 As shown, a visual sintering-free flat sand filling model device includes a flat sand filling model, a model stamping device, and a model fixing bracket. The flat sand filling model is composed of a flat model main body 1, a model upper cover plate 2, a fixed steel plate 3; bolts 4; and a simulated well hole 5. The length of the main body of the model is 100mm, the width is 76mm, and the wall thickness is 20mm; 6 pieces are evenly distributed on both sides of the wide side The injection-production wellholes are simulated, and the upper cover plate simulates the actual injection-production well pattern layout of the reservoir.

[0044] The main body 1 of the flat sand filling model is placed horizontally, and the model is divided into partitions according to the needs of the experiment, separated by partition plates, and the mixed sand is loaded into the corresponding positions in stages. Carefully install and fix simulated injection-producti...

Embodiment 2

[0056] The formula listed in Table 1 below is taken as an example, and the quartz sand and clay of different particle sizes are weighed in proportion, and part of the quartz sand surface is subjected to wettability treatment as required. According to the above scheme, a sand filling model was made to carry out the physical simulation experiment of different types of reservoir layer interchange and variable flow line. The permeability was designed to be divided into four equal strips from high to low for sand filling. After the model was made, firstly divide The permeability of strips with different permeability was measured by air. The liquid permeability of each seepage zone was measured separately for the fully saturated brine. The model is saturated with oil, and the nine-point well pattern is reversed. Wells 2, 3, 5, and 8 are injection wells, and wells 6 and 9 are production wells to simulate the simple injection-production unit of the reservoir. The left and right ends o...

Embodiment 3

[0060] The formula listed in Table 2 below is taken as an example, and the quartz sand and clay of different particle groups are weighed in proportion, and the surface of the quartz sand is subjected to wettability treatment according to the research needs. According to the above scheme, a simulation experiment of the evolution law of positive rhythmic thick oil layer and high water consumption zone was made. According to the actual permeability distribution of the reservoir, the model was divided into three areas with L-shaped distribution according to the similarity principle. The hypertonic area of 3000-4500mD accounts for 2 / 3 and is distributed on the left and upper part of the model; the medium-osmotic area of 1500-2200mD accounts for 1 / 6; the low-osmotic area of 500-900mD accounts for 1 / 6 and is located at the lower right of the model; the left and right ends of the model Can be used as a pressure monitoring point. The injection end uses a high-precision ISCO pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com