Preparation method of temperature-resistant straw

A straw and temperature-resistant technology, which is applied in the field of preparation of heat-resistant straws, can solve problems such as inconvenient use, insufficient strength, and inconvenient popularization, and achieve the effects of cost reduction, fast molding speed, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

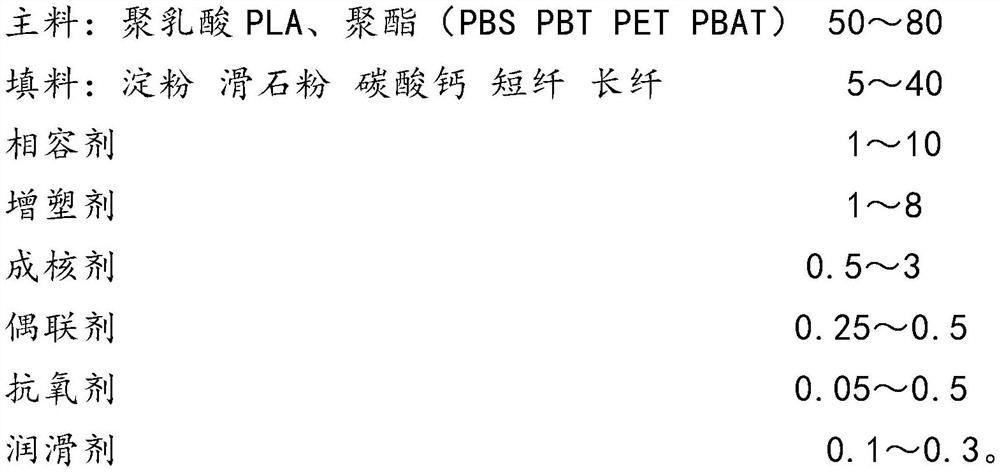

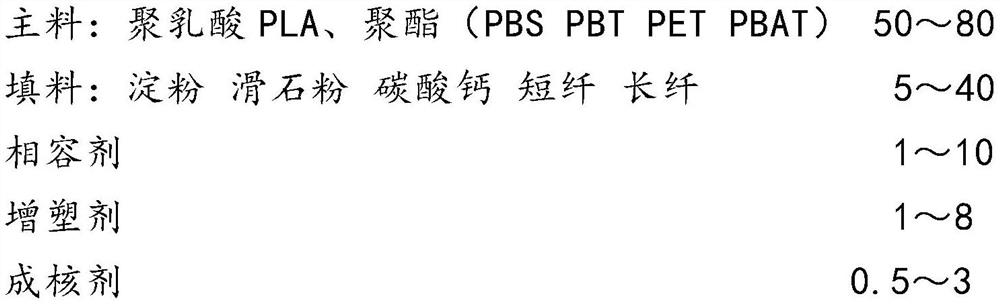

Method used

Image

Examples

Embodiment 1

[0047] 50 parts of polylactic acid, 20 parts of polyadipate / butylene terephthalate, 20 parts of starch, 10 parts of short fiber, 3 parts of compatibilizer, 1 part of plasticizer, 0.5 part of nucleating agent, coupling Agent 3 parts, antioxidant 1010, 168 is 0.05, 0.05 parts.

[0048] Put 20 parts of starch and 1 part of plasticizer into the high mixer and stir for 10-50 minutes; then mix the plasticized starch and other components in the mixer evenly; and extrude through the straw extruder Cut the tube and place it in a hot air oven at 80°C to 100°C for 10min to 60min to obtain the finished product A.

Embodiment 2

[0050]50 parts of polylactic acid, 20 parts of polybutylene succinate, 20 parts of starch, 10 parts of short fiber, 3 parts of compatibilizer, 2 parts of plasticizer, 1.5 parts of nucleating agent, 3 parts of coupling agent, antioxidant Agents 1010 and 168 are 0.05 and 0.05 parts.

[0051] Put 20 parts of starch and 3 parts of plasticizer into the high mixer and stir for 10-50 minutes; then mix all the raw materials in the mixer evenly, and extrude the cut tube through the straw extruder, and put it into Process in a hot air oven at 80°C to 100°C for 10min to 60min to obtain finished product B.

Embodiment 3

[0053] 50 parts of polylactic acid, 20 parts of polybutylene succinate, 20 parts of starch, 10 parts of long fiber, 3 parts of compatibilizer, 3 parts of plasticizer, 2 parts of nucleating agent, 3 parts of coupling agent, antioxidant Agents 1010 and 168 are 0.05 and 0.05 parts.

[0054] The preparation method is as shown in Example 2, and the finished product C is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com