Degradable material and preparation method thereof

A technology for degrading materials and degrading additives, applied in the field of degradable materials and their preparation, can solve the problems of wood consumption, inability to be widely used and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

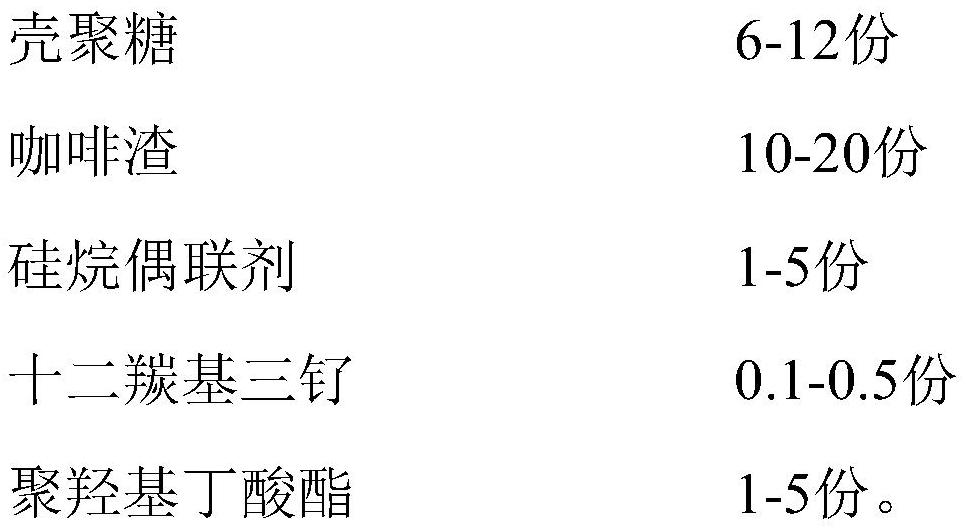

[0034] A degradable material, comprising the following raw materials in parts by weight:

[0035]

[0036] The molecular weight of the polylactic acid is 150,000; the chitin is chitin 9012-76-4 produced by Xi'an Aosai Biotechnology Co., Ltd.; the PBAT resin is PBAT produced by Suzhou Xinfeiyang Engineering Plastics Co., Ltd. Resin TH801T.

[0037] Described modified bamboo fiber is made through the following steps:

[0038] S1, take by weighing 5g bamboo fiber, pulverize to particle diameter and be less than 100 orders, add the bamboo fiber after pulverizing 200mL concentration 0.1mol / L containing IO4 -1 Add 8 mL of sodium hydroxide solution with a concentration of 0.1 mol / L to the solution, heat to 50°C, stir for 20 minutes, then wash with deionized water once, then filter the deionized water and spray with liquid nitrogen to freeze for 3 minutes , then add the frozen bamboo fiber into the grinding device and grind for 1min to obtain the bamboo fiber bundle, which is set...

Embodiment 2

[0053] A degradable material, comprising the following raw materials in parts by weight:

[0054]

[0055] The molecular weight of the polylactic acid is 170,000; the chitosan is chitosan 9012-76-4 produced by Xi'an Aosay Biotechnology Co., Ltd.; the PBAT resin is PBAT produced by Suzhou Xinfeiyang Engineering Plastics Co., Ltd. Resin TH801T.

[0056] Described modified bamboo fiber is made through the following steps:

[0057] S1, take by weighing 6g bamboo fiber, pulverize to particle diameter less than 100 orders, add the bamboo fiber after pulverizing 210mL concentration 0.1mol / L containing IO4 -1 Add 8.5 mL of sodium hydroxide solution with a concentration of 0.1 mol / L to the solution, heat to 55°C, stir for 25 minutes, then wash with deionized water once, then filter the deionized water and spray it with liquid nitrogen to freeze 3min, then add the frozen bamboo fiber into the grinding device and grind for 2min to obtain the bamboo fiber bundle, which is for subsequ...

Embodiment 3

[0072] A degradable material, comprising the following raw materials in parts by weight:

[0073]

[0074] The molecular weight of the polylactic acid is 200,000; the chitosan is chitosan 9012-76-4 produced by Xi'an Aosai Biotechnology Co., Ltd.; the PBAT resin is PBAT produced by Suzhou Xinfeiyang Engineering Plastics Co., Ltd. Resin TH801T.

[0075] Described modified bamboo fiber is made through the following steps:

[0076] S1, take by weighing 7g bamboo fiber, pulverize to particle diameter less than 100 orders, add the bamboo fiber after pulverizing 220mL concentration 0.1mol / L containing IO4 -1Add 9 mL of sodium hydroxide solution with a concentration of 0.1 mol / L to the solution, heat to 60°C, stir for 30 minutes, then wash with deionized water twice, then filter the deionized water and spray with liquid nitrogen to freeze for 4 minutes , then add the frozen bamboo fiber into the grinding device and grind for 31min to obtain the bamboo fiber bundle, which is for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com