Sewage tunnel segment structure and construction method thereof

A technology for tunnel segment and sewage, which is applied in infrastructure engineering, waterway system, sewer system, etc., can solve the problems of cumbersome procedures, hand hole blocking, slow construction speed, etc., to reduce project investment and reduce water leakage. , the effect of a high degree of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

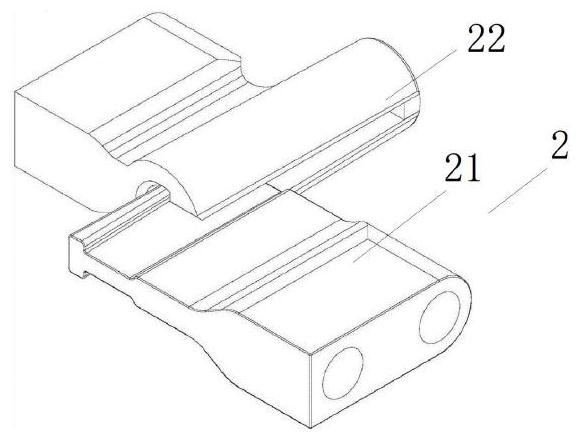

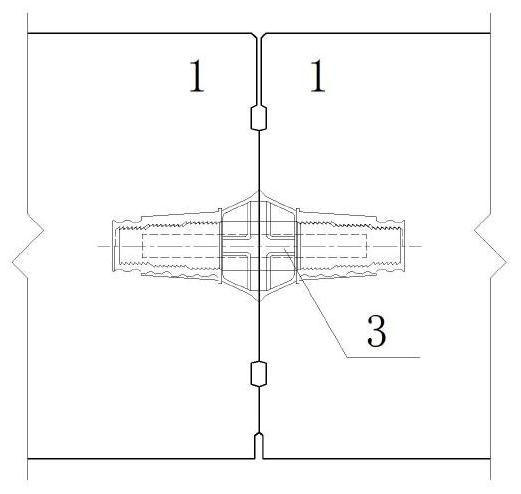

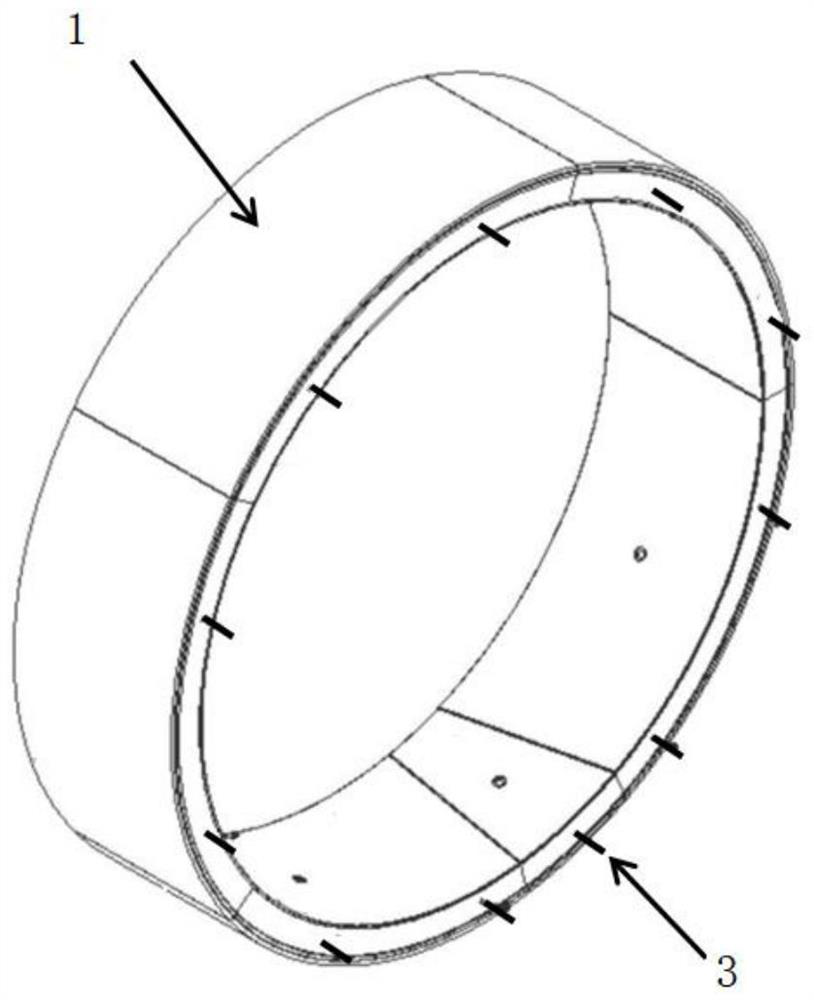

[0035] Referring to the accompanying drawings, it can be seen that the sewage tunnel segment structure is characterized in that it includes a shield segment 1, a tapered connector 2 and a plug-in connector 3, and the upper and lower ends of the side of the shield segment 1 are tapered. Part 2, the longitudinal seams of multiple shield segments 1 are connected by tapered connectors 2, and the annular seams of multiple shield segments 1 are connected by plug-in connectors 3;

[0036] Both the longitudinal seam and the annular seam of the shield segment 1 are provided with a water-stop structure 4;

[0037] A PVC sheet 11 is pre-embedded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com