Seamless steel pipe having exceptional resistance to sulfuric acid dew-point corrosion, and method for manufacturing seamless steel pipe

A technology for seamless steel pipes and manufacturing methods, applied in the field of seamless steel pipes, seamless steel pipes and their manufacturing, capable of solving the problems of pipe life reduction, peeling, environmental impact, etc., achieving excellent manufacturability, excellent suppression effect, and resistance to sulfuric acid dew point Excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

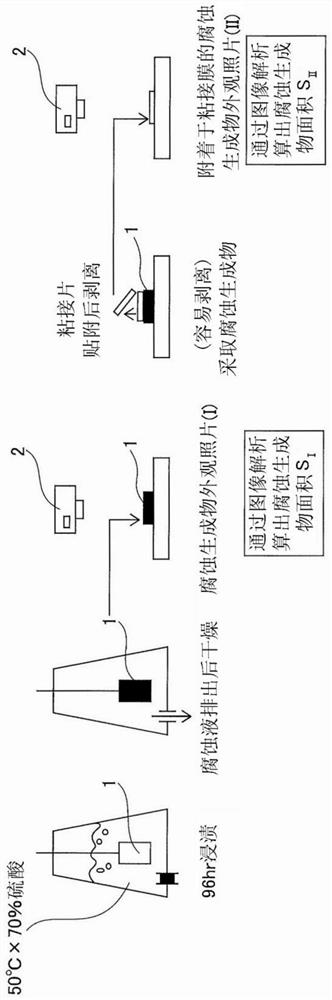

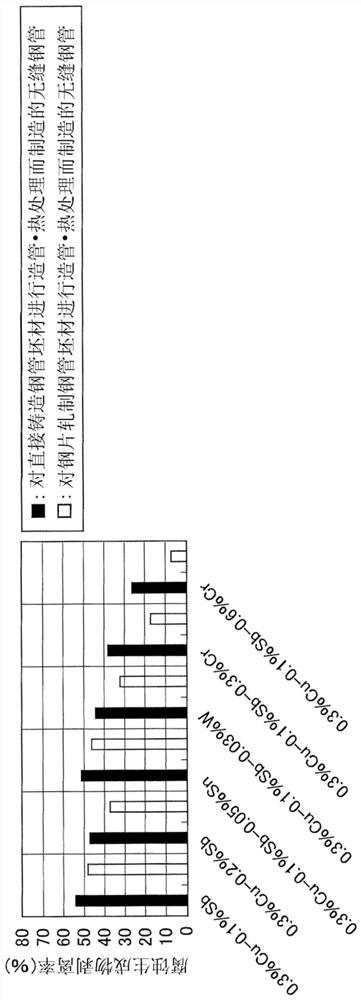

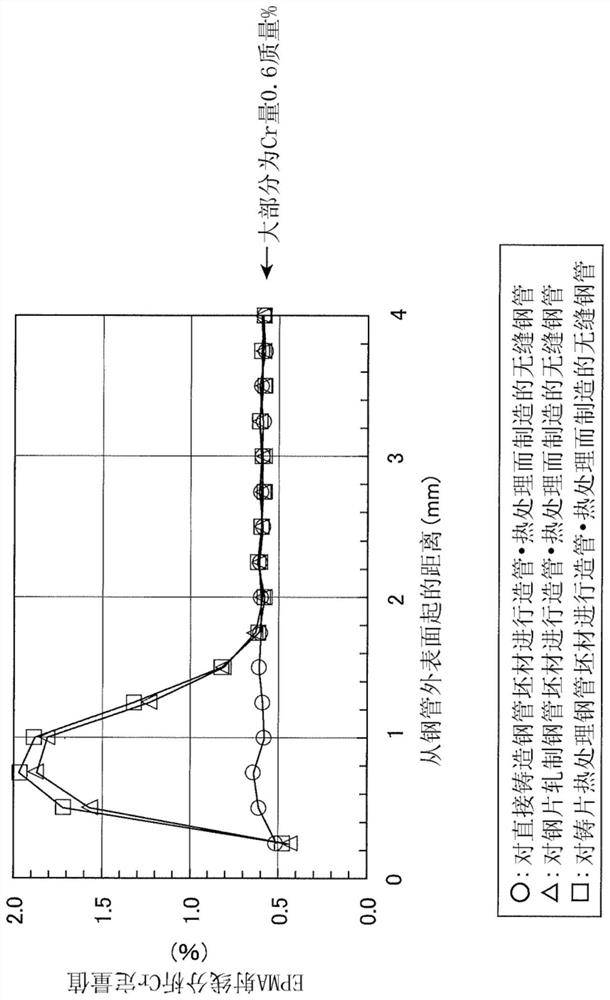

[0110] Steels having the chemical compositions shown in Tables 1 and 2 were smelted by a converter method, followed by continuous casting to obtain slabs. In the continuous casting, two methods of casting a slab having a rectangular cross-section having a thickness of 300 mm x 400 mm in width and casting a slab having a circular cross-section having a diameter of 190 mm were carried out.

[0111] The slab having a rectangular cross-section is heated at a predetermined heating temperature, and is formed into a steel pipe material with a diameter of 190 mm or 140 mm by hot rolling (slab-rolled steel pipe material). The seamless steel pipe produced using the above-mentioned steel pipe blank is described as "strip rolling" in the column of the steel pipe blank classification in Table 3, Table 4, and Table 5. In addition, the heating temperature in the steel sheet rolling, the heating time from 900° C. to the heating temperature, and the steel sheet rolling completion temperature w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com