Device for replacing non-initial-set cement paste and construction method

A technology of mud and water coagulation, which is applied in the field of cement pouring, can solve the problems of delayed static load test detection date, affecting the improvement of single pile bearing capacity, and blockage of post-grouting pipes, so as to achieve perfect internal cleaning, not easy to move, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

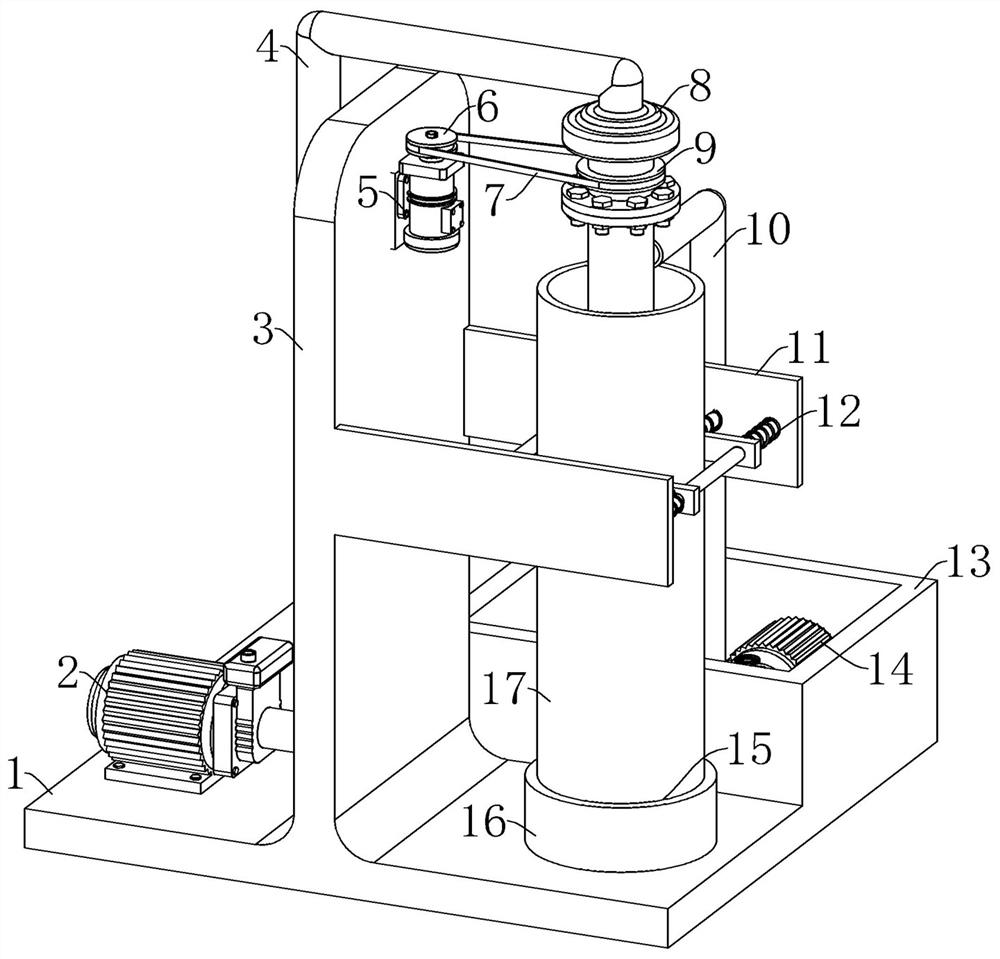

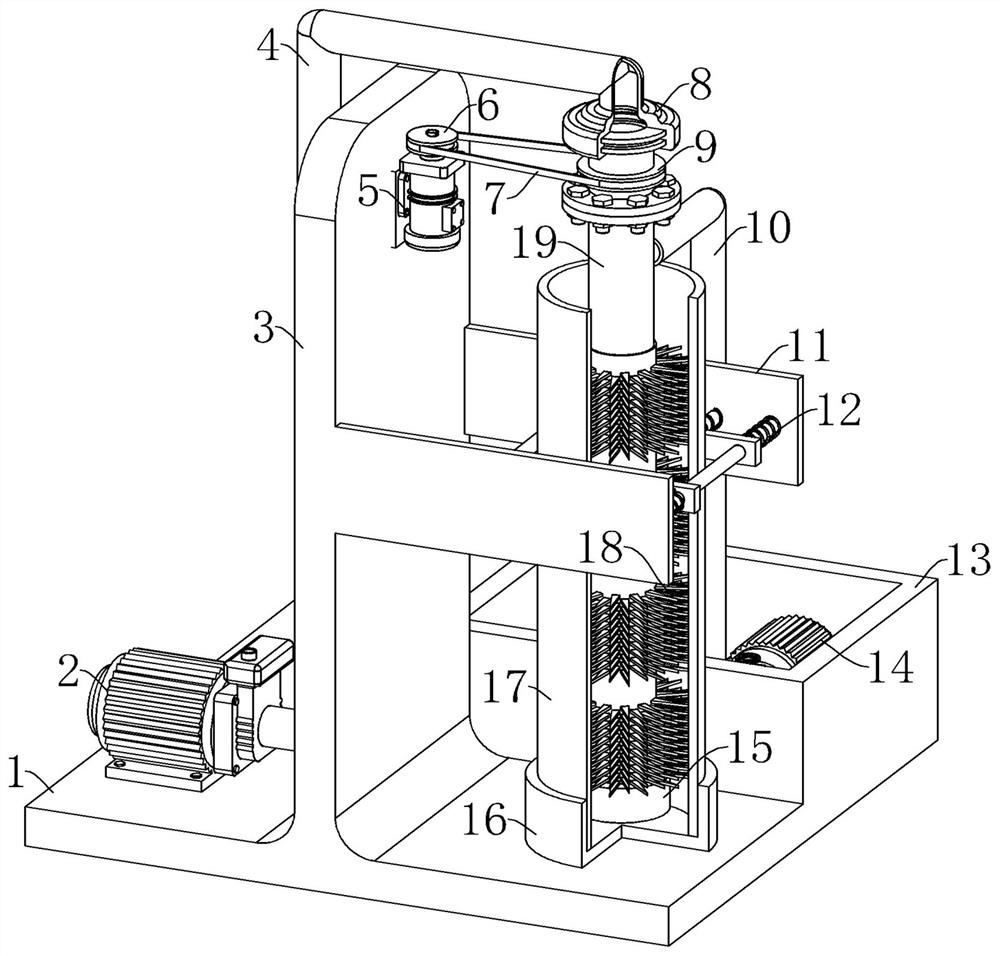

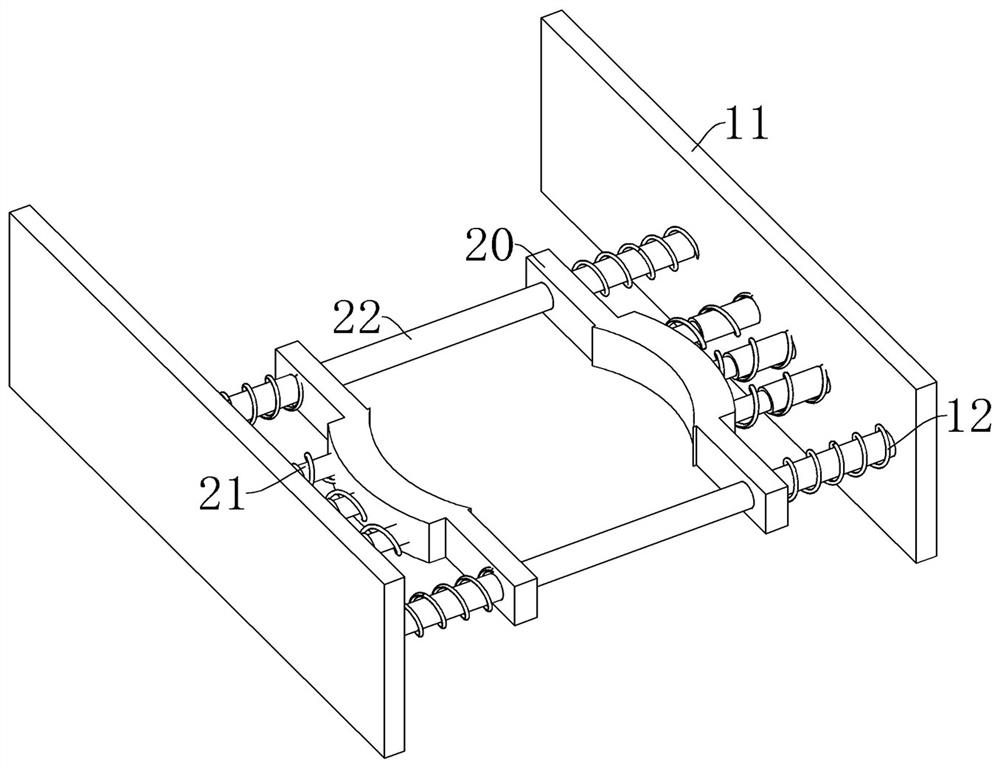

[0034] refer to Figure 1-5 : A kind of device for displacing uninitially set cement slurry, comprising: a base 1 with a support plate 3 on the top; a clamping mechanism, arranged on the support plate 3, for clamping the cleaned pipe, wherein The mechanism includes a mounting part, a power buffer part, two splints 20, and the two splints 20 are respectively slidably connected to the two ends of the mounting part; The mechanism includes a driving part, a connecting part, a transmission part, a water suction pipe 19 and a cleaning brush 18. The water suction pipe 19 is arranged at the center of the clamping mechanism, and the cleaning hair brush 18 is sleeved on the outer surface of the water suction pipe 19.

[0035] In this embodiment: the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com