Processing technology of single-needle gold feeding base

A processing technology and base technology, which is applied in the field of single-needle gold feeding base processing technology, can solve problems such as complicated procedures, and achieve the effects of simplifying the process flow, reducing labor intensity, and reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

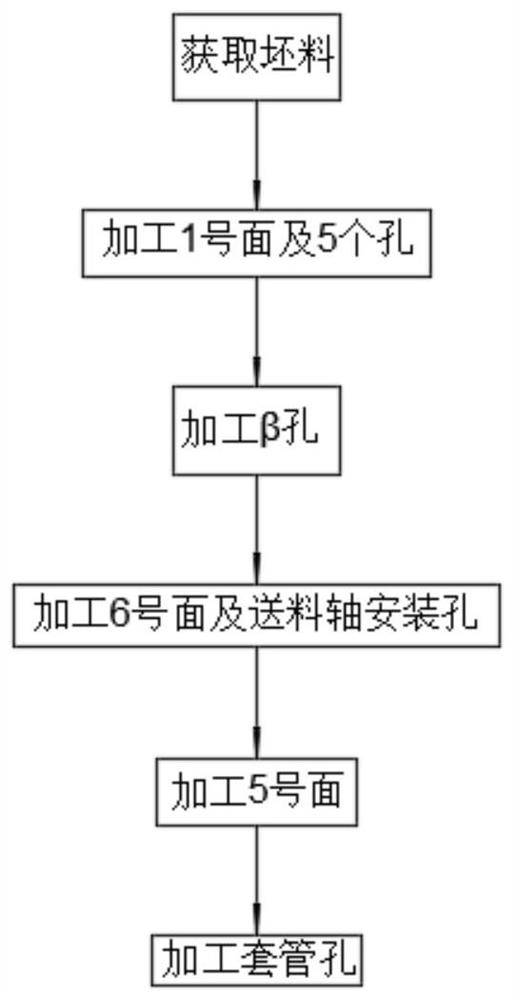

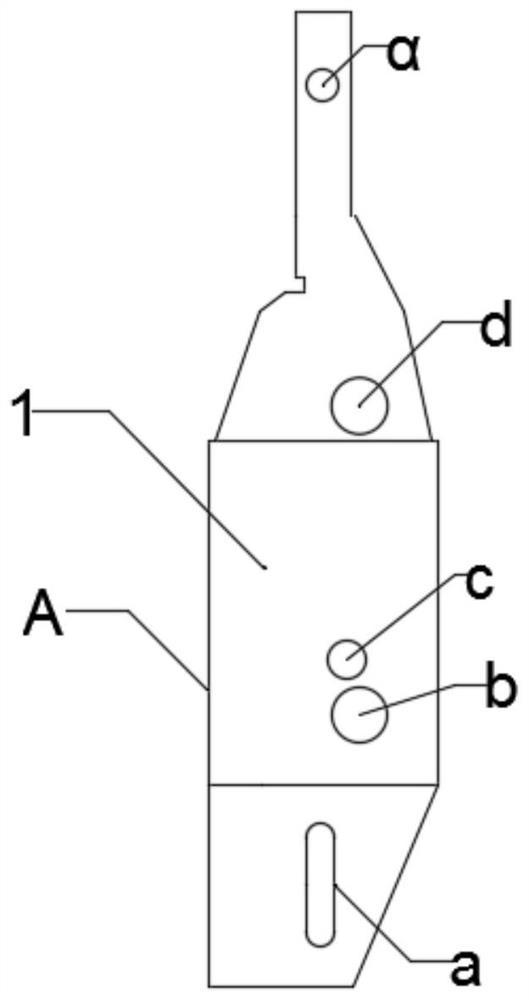

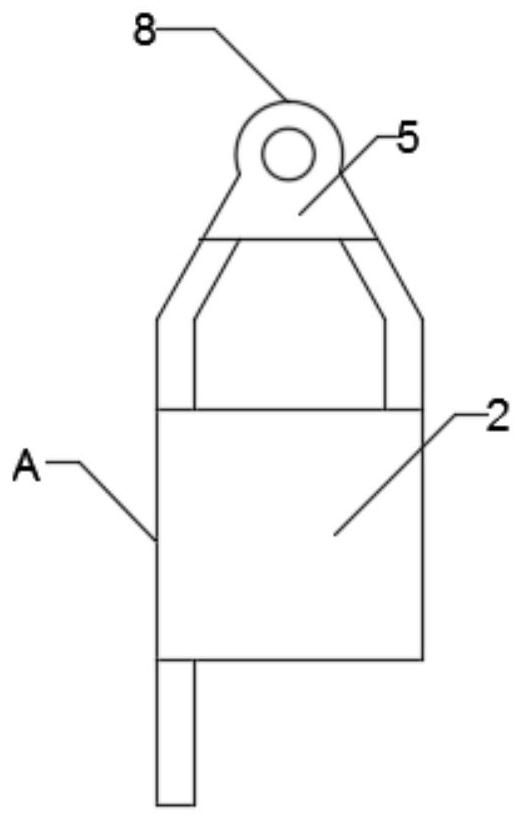

[0035] Such as Figure 1-11 As shown, a processing technology for a single-needle gold feeding base is characterized in that the specific steps are as follows: Step 1: Obtain a blank B, and the blank B is initially provided with 3 holes, which are waist-shaped adjustment hole a, sleeve Hole f and feeding shaft installation hole e, No. 1 surface 1, No. 5 surface 5, No. 6 surface 6 of the blank B, waist-shaped adjustment hole a, casing hole f and feeding installation hole e all leave a margin; Step 2: Process No. 1 surface 1 and 5 through holes through the machining center, firstly mill the No. 1 surface 1 to remove the remaining margin to the product standard size, and then drill and tap through the machining center to obtain b holes b, C hole c, d hole d, α hole α4 threaded holes, then remove the margin of the waist adjustment hole a to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com