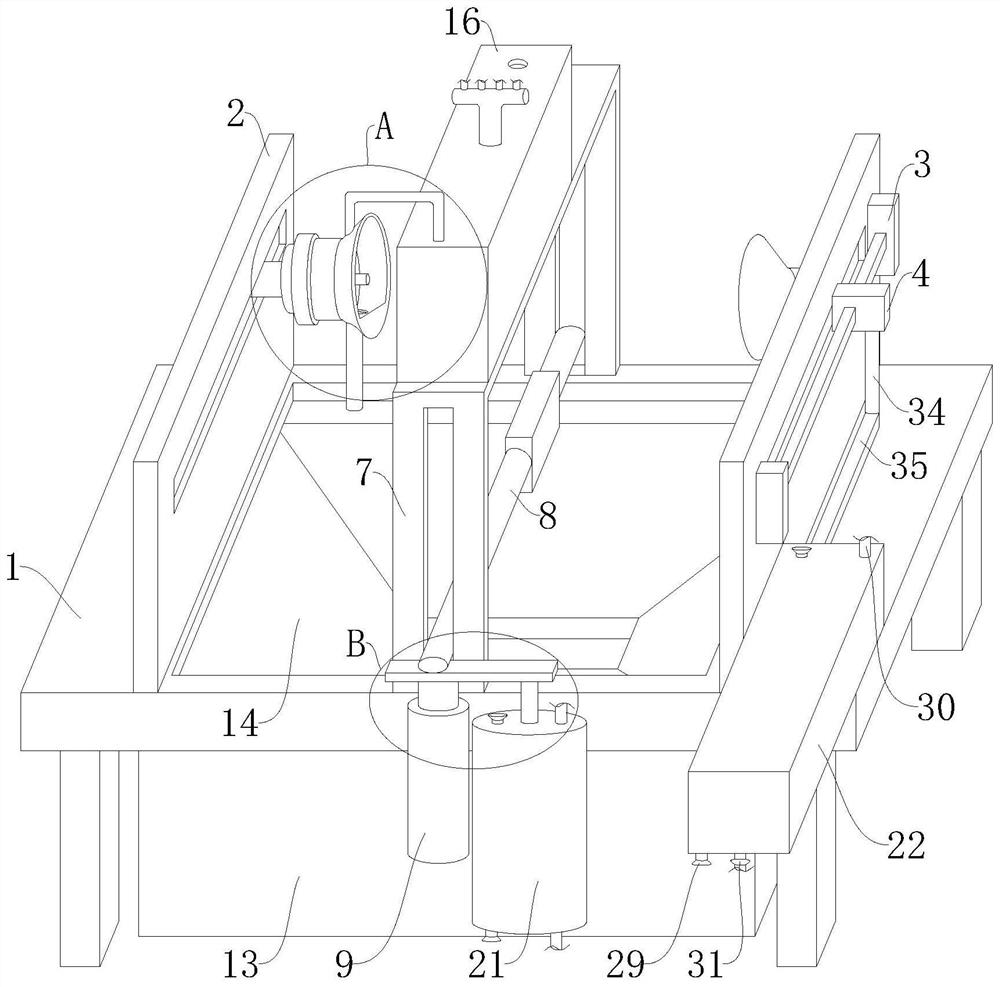

Multi-station numerical control bilateral milling machine

A technology with two digits and two controls, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of splashing around, cleaning and collecting time delays, etc., and achieve the effect of preventing the funnel from being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

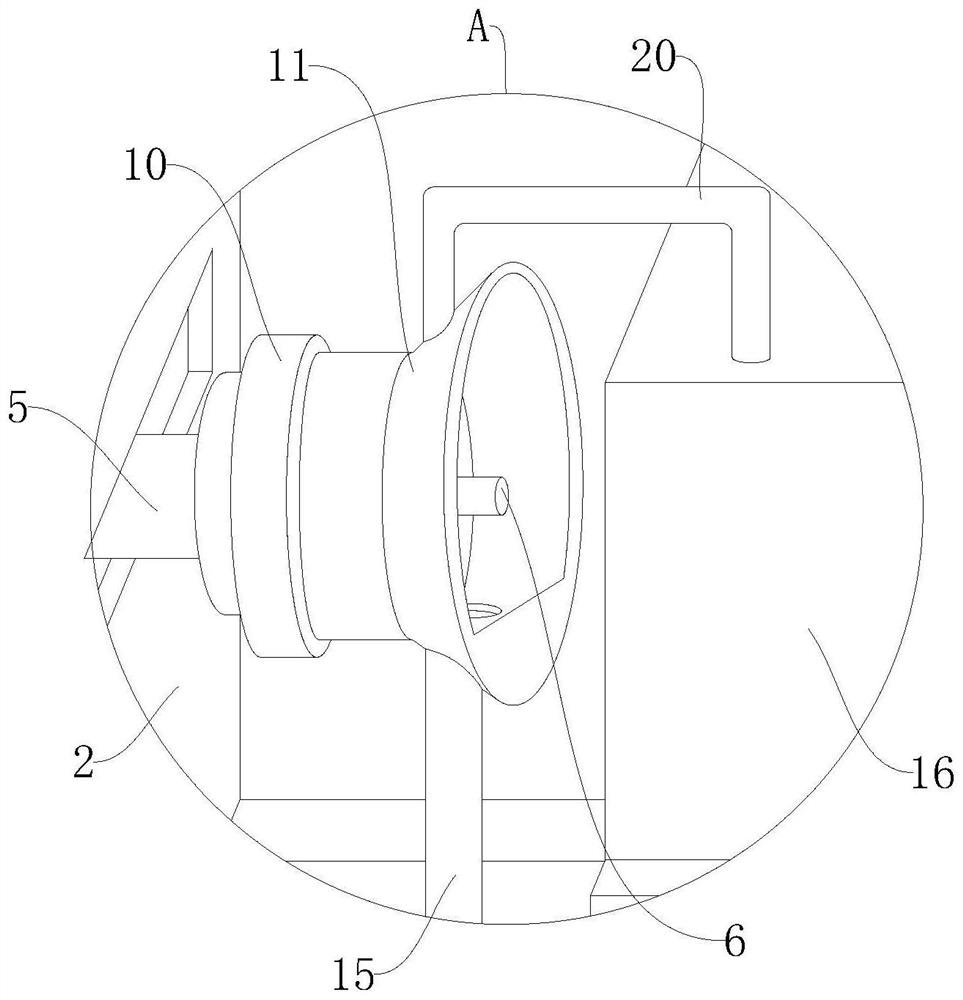

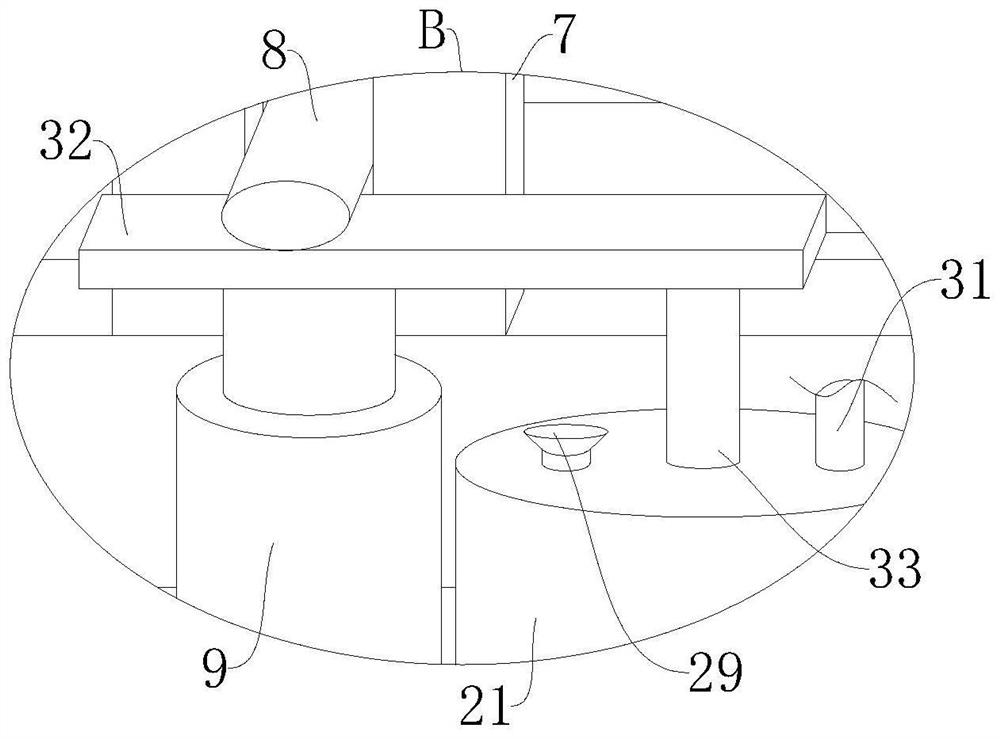

[0055] As an embodiment of the present invention, refer to figure 1 , Figure 8 and Figure 9 The inflation mechanism includes a first cylinder 21 and a second cylinder 22 fixedly installed on the side wall and the top wall of the workbench 1 respectively, and the first cylinder 21 and the second cylinder 22 are respectively equipped with a first piston plate 23 and a second cylinder 22. Two piston plates 24, the first piston plate 23 divides the first cylinder 21 into the first cavity 25 and the second cavity 26 from top to bottom, and the second piston plate 24 divides the second cylinder 22 into the second cavity from left to right. Three cavity 27 and the 4th cavity 28, on the top wall of the first cavity 25, the bottom wall of the second cavity 26, the top wall of the 3rd cavity 27 and the side wall of the 4th cavity 28 all fixed installations The first check valve 29 and the intake pipe 30 communicating with the gas cylinder 16 are arranged, and the second check valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com