Paperboard cutter for carton packaging box

A packaging box and cutter technology, used in paper/cardboard containers, packaging, transportation and packaging, etc., can solve the problems of high resistance to moving the blade down, poor cutting effect, and large consumption of blade, so as to reduce the cutting resistance. , Improve the cutting efficiency and the effect of efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

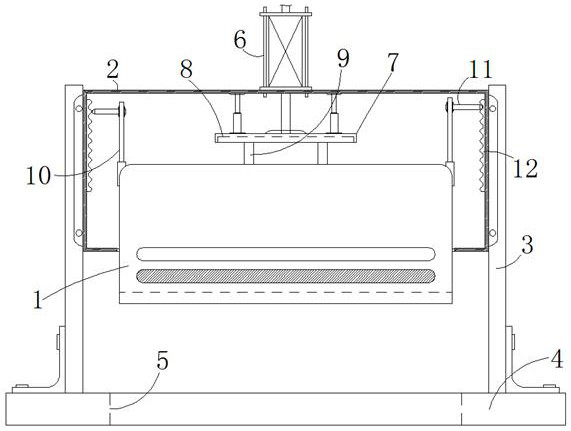

[0030] Such as figure 1 As shown, the cardboard cutter includes a knife plate 1, the knife plate 1 is slid up and down and installed on the lower end surface of the shell 2, and the side of the shell 2 is fixed on the platform 4 through the column 3, and the platform 4 is provided with a knife plate 1 corresponding up and down. A hydraulic rod 6 is installed on the casing 2, and the output end of the hydraulic rod 6 is connected with the upper end surface of the knife plate 1 through the connecting rod 7 and the vertical rod 9, and also includes a chute 8, which is set on the lower end surface of the connecting rod 7 The top of the chute 8 and the vertical bar 9 is slidingly connected, and the bottom end of the vertical bar 9 is fixedly connected with the knife plate 1; the stacked cardboard is located between the knife plate 1 and the platform 4, and the width of the cardboard is smaller than that of the knife plate 1 Length, when the hydraulic rod 6 was running, the knife pl...

Embodiment 2

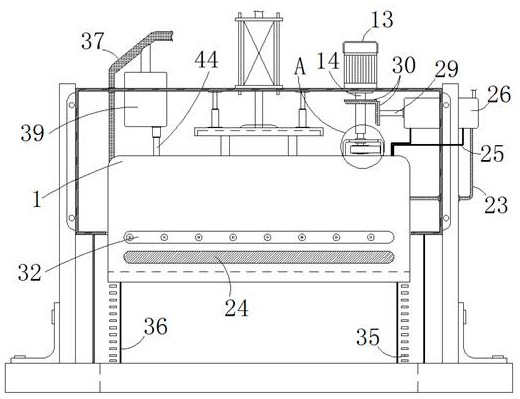

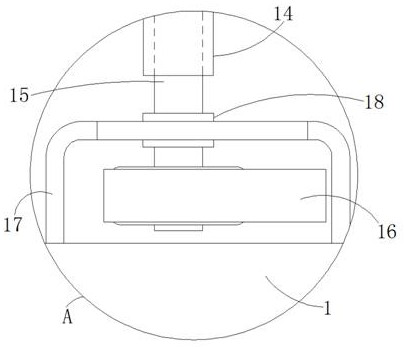

[0033] Such as figure 2 and image 3 As shown, the difference from Embodiment 1 is that in this embodiment the vibrating mechanism is composed of a motor 13, a vertical cylinder 14, a vertical shaft 15 and a cam plate 16, and the top of the vertical cylinder 14 with a square slot and the top of the motor 13 are provided inside. The output end is connected, and the inside of the vertical tube 14 is vertically slidingly connected with the vertical shaft 15 below it. The bottom end of the vertical shaft 15 is fixed with a horizontally distributed cam plate 16, and the right side surface of the cam plate 16 is connected to the inner wall of the vibration box 17. contact, and the top wall of the vibrating box 17 and the slider 18 are horizontally slidingly connected, and the slider 18 is rotatably connected to the vertical shaft 15 passing through, the motor 13 drives the cam plate 16 to rotate, and the eccentrically installed cam plate 16 drives and fixes the The vibrating box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com