Green recoverable and degradable corrugated carton and production method thereof

A corrugated box and corrugated paper technology, applied in the field of carton preparation, can solve the problems of limited strength and impact resistance of corrugated board, reduce packaging space, waste resources, etc., and achieve the effects of being beneficial to environmental protection, saving wood, and being easy to restore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

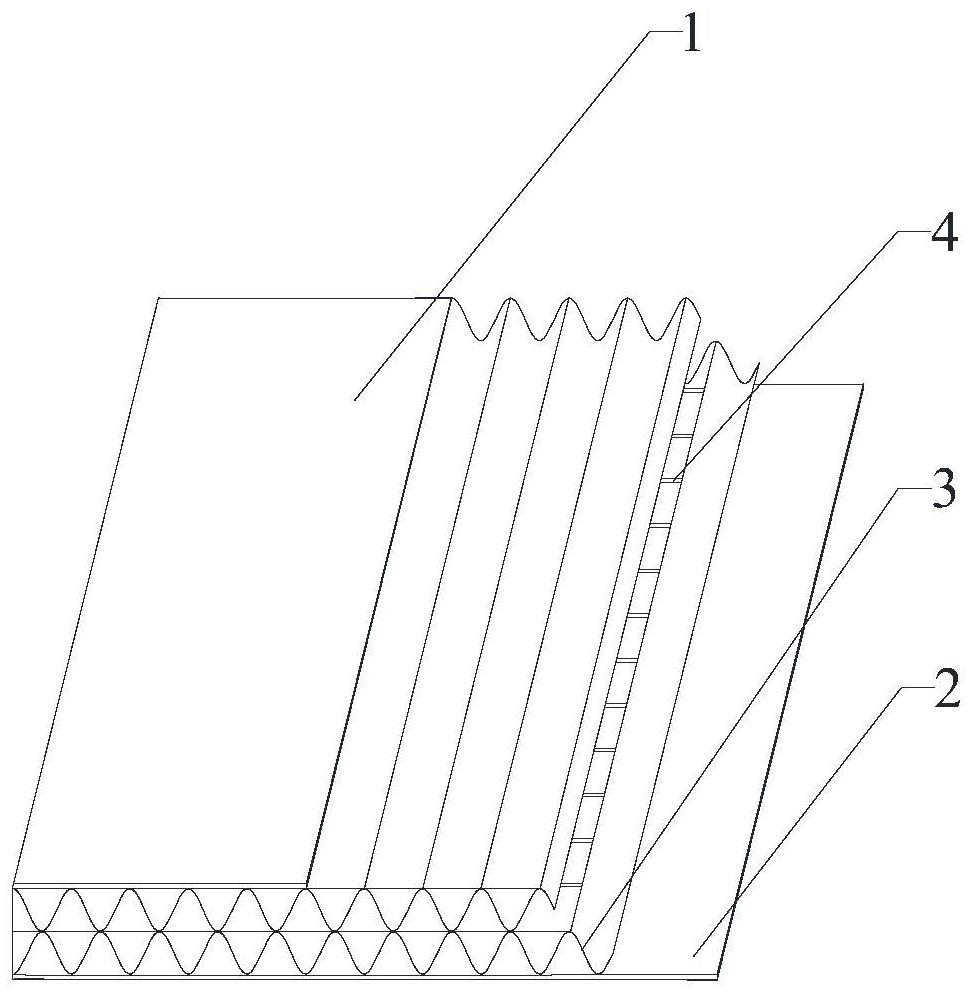

[0024] Please refer to Figure 1-2 , a green recyclable and degradable corrugated box, the corrugated box is prepared from high-elastic calcium-plastic corrugated cardboard; the high-elastic calcium-plastic corrugated cardboard includes an outer plane cardboard 1, two layers of calcium-plastic Corrugated paper 2 and bottom plane cardboard 3;

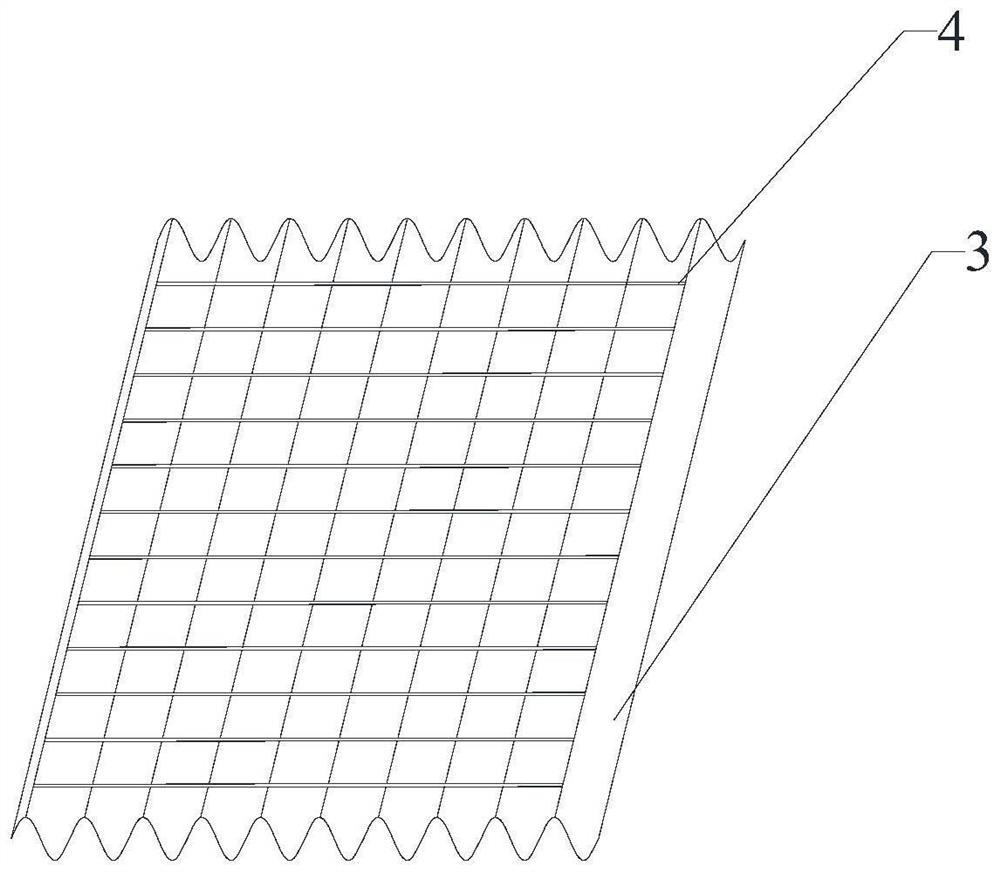

[0025] The cross-section of the calcium-plastic corrugated paper 2 is a wave-shaped concave-convex surface, and the shape of each layer of the calcium-plastic corrugated paper 2 is the same, and the vertices of the convex surfaces between the adjacent calcium-plastic corrugated paper 2 are connected; and the adjacent calcium-plastic corrugated paper 2 A plurality of cotton threads 4 are arranged along the wave extension direction of the calcium-plastic corrugated board 2.

[0026] The calcium-plastic corrugated paper 2 is prepared from polyethylene, calcium carbonate, starch, zinc stearate, barium stearate and antioxidant 1010 according...

Embodiment 2

[0033] Please refer to Figure 1-2 , a green recyclable and degradable corrugated box, the corrugated box is prepared from high-elastic calcium-plastic corrugated cardboard; the high-elastic calcium-plastic corrugated cardboard includes an outer plane cardboard 1, two layers of calcium-plastic Corrugated paper 2 and bottom plane cardboard 3;

[0034] The cross-section of the calcium-plastic corrugated paper 2 is a wave-shaped concave-convex surface, and the shape of each layer of the calcium-plastic corrugated paper 2 is the same, and the vertices of the convex surfaces between the adjacent calcium-plastic corrugated paper 2 are connected; and the adjacent calcium-plastic corrugated paper 2 A plurality of cotton threads 4 are arranged along the wave extension direction of the calcium-plastic corrugated paper 2 .

[0035] The calcium-plastic corrugated paper 2 is prepared from polyethylene, calcium carbonate, starch, zinc stearate, barium stearate and antioxidant 1010 accordin...

Embodiment 3

[0042] Please refer to Figure 1-2 , a green recyclable and degradable corrugated cardboard box, the corrugated cardboard box is prepared from high-elastic calcium-plastic corrugated cardboard; Corrugated paper 2 and bottom plane cardboard 3;

[0043] The cross-section of the calcium-plastic corrugated paper 2 is a wave-shaped concave-convex surface, and the shape of each layer of the calcium-plastic corrugated paper 2 is the same, and the vertices of the convex surfaces between the adjacent calcium-plastic corrugated paper 2 are connected; and the adjacent calcium-plastic corrugated paper 2 A plurality of cotton threads 4 are arranged along the wave extension direction of the calcium-plastic corrugated paper 2 . The calcium-plastic corrugated paper 2 is prepared from polyethylene, calcium carbonate, starch, zinc stearate, barium stearate and antioxidant 1010 according to the following weight ratio 100:200:100:1:1:1. The cotton threads 4 are flat, and the adjacent cotton thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com