Oil injection funnel

A funnel and oil filling technology, applied in the field of brake oil filling device, can solve problems such as the hidden danger of brake oil injection, and achieve the effects of simple use, avoiding brake oil pollution and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

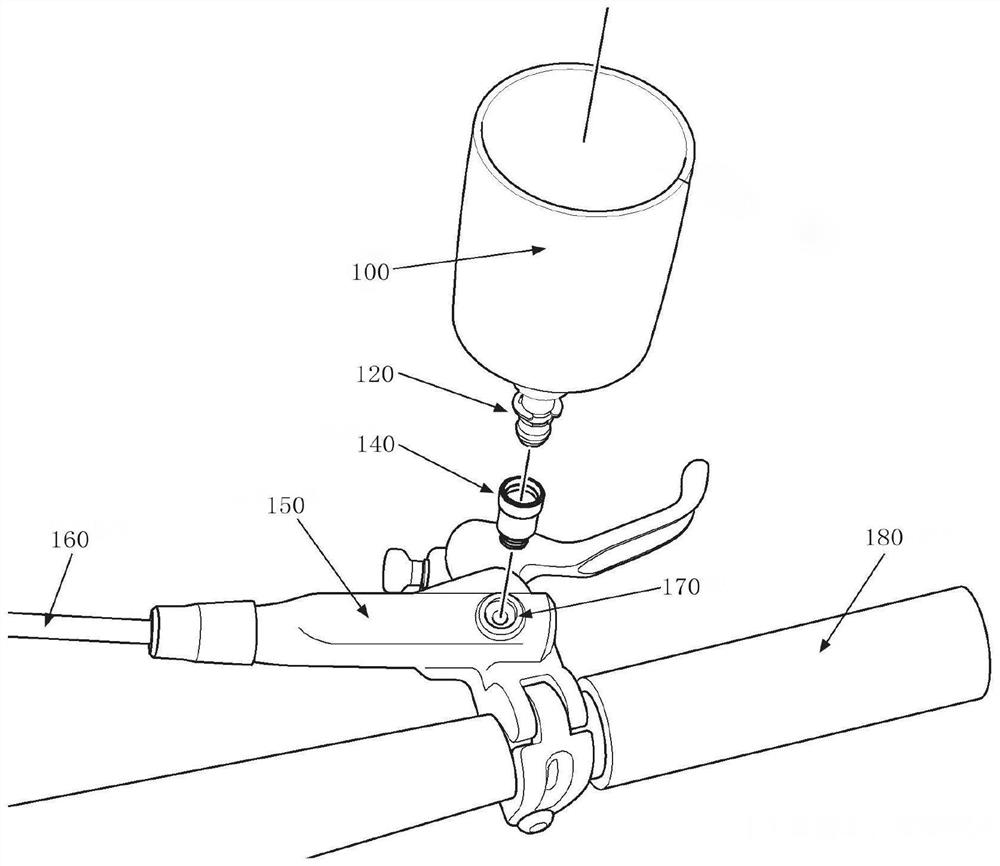

[0053] Embodiment 1: a kind of oil filling funnel, see Figure 1 to Figure 16 .

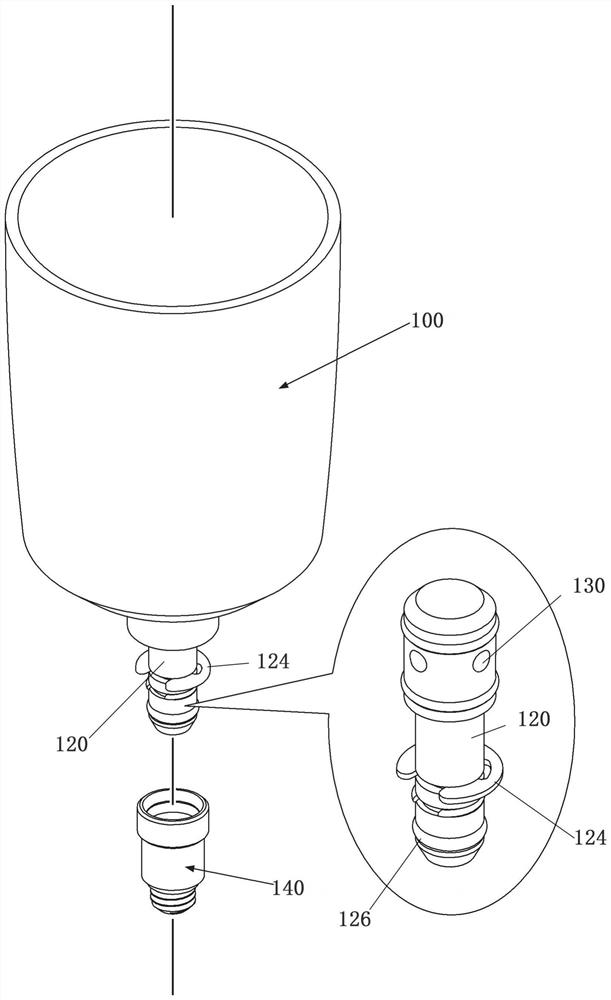

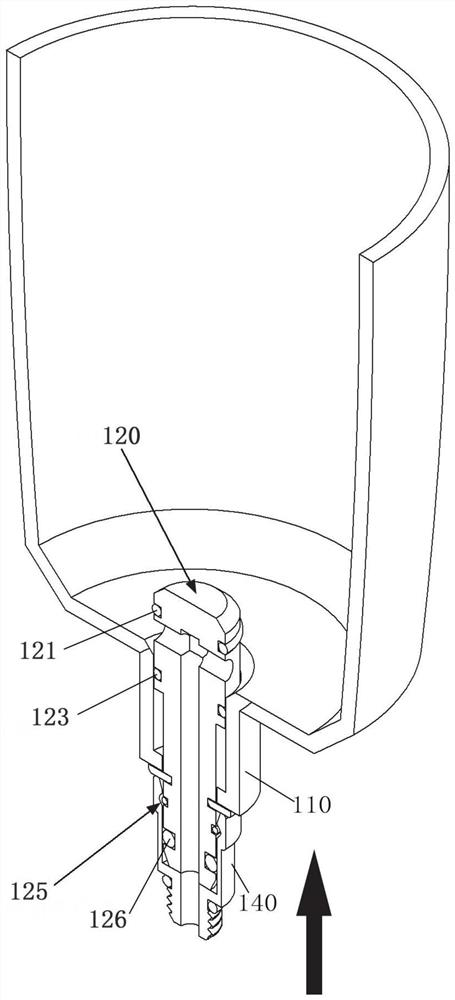

[0054]It includes a bucket body 100 for holding oil and a bucket neck 120. The bucket body 100 is a cylindrical structure with an open top, and the bucket neck 120 is a tubular structure with a main oil hole 127 in the middle and is connected to the bucket. Body 100 is movably plugged; specifically, the upper end of the main oil hole 127 does not pass through the top of the bucket neck and ends at the top of the bucket neck 120, and the lower end of the main oil hole 127 runs through the lower end of the bucket neck 120 It is an open end, and at the same time, four oil distribution holes 122 , 128 , 129 , 130 communicating with the oil injection hole 127 are opened on the upper circumferential side wall of the bucket neck 120 .

[0055] Further, the bucket neck 120 on the upper and lower sides of the oil separation hole 127 is respectively sleeved with an upper seal 121 and a lower seal 123, the...

Embodiment 2

[0078] Embodiment 2. This embodiment is used on the structure described in Embodiment 1. During use, a syringe is used to cooperate with the bucket body to remove air from the brake caliper. The process is as follows:

[0079] 1. First, install the thread of the adapter on the oil filling port of the brake handle.

[0080] 2. The operator holds the bucket body and inserts the bucket body into the upper end of the bucket neck.

[0081] 3. The operator holds the bucket body and inserts the lower end of the bucket neck into the adapter. When the bucket neck is inserted into the bottom of the adapter, the steel wire retaining ring 125 for the shaft will be snapped into the slot 142 of the adapter, so that the oil distribution port is open.

[0082] 4. Choose a medical syringe and fill it with brake oil, and connect it to the oil filling port of the brake caliper through a hose (there are two oil filling holes for hydraulic brakes, which are respectively located on the brake handle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com