A large fluidity and high resistance to dispersion cast-in-situ pile concrete containing machine-made sand and dust-collecting stone powder

A technology of machine-made sand and cast-in-place piles, which is applied in the field of building materials, can solve the problems of high glue consumption and difficulty in using dust-collected stone powder on site, so as to improve work performance, solve the shortage of fly ash resources, and reduce the glue consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

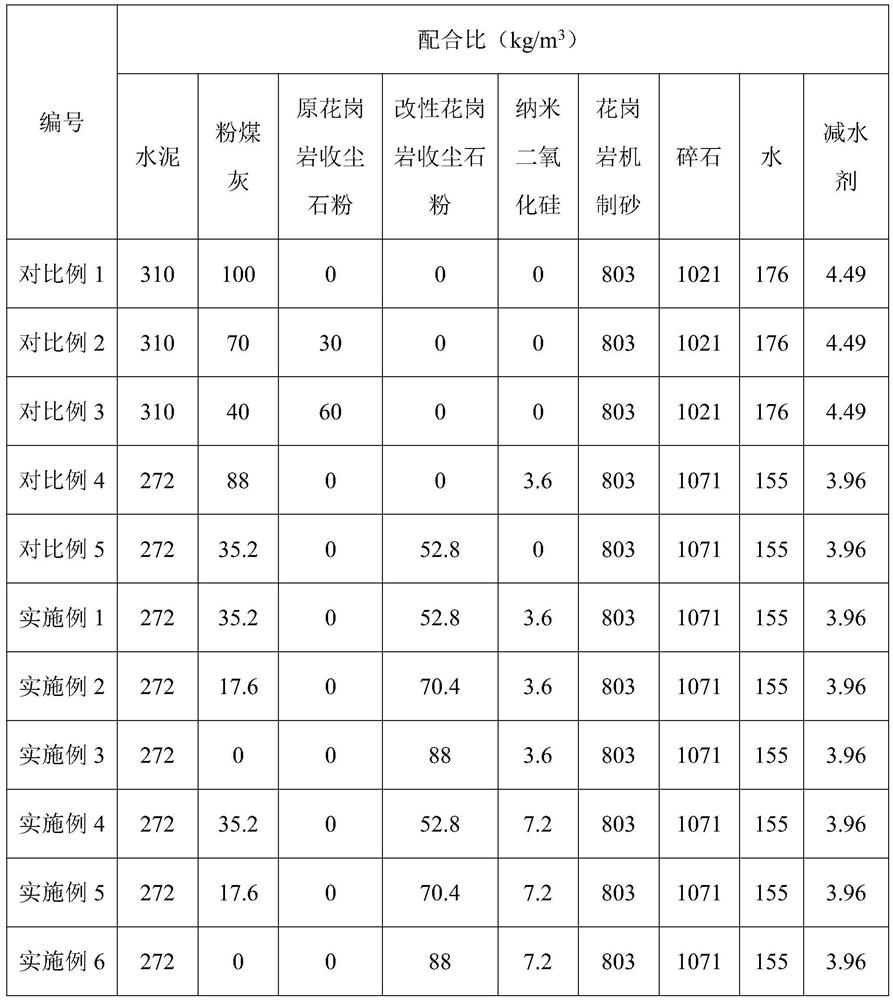

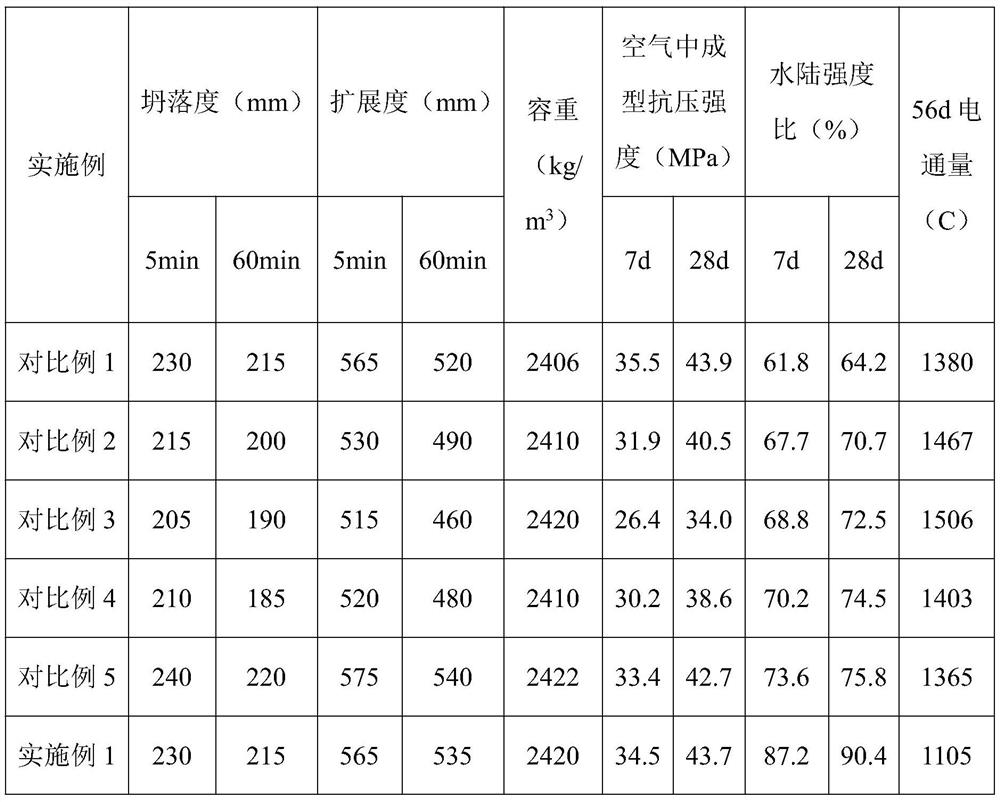

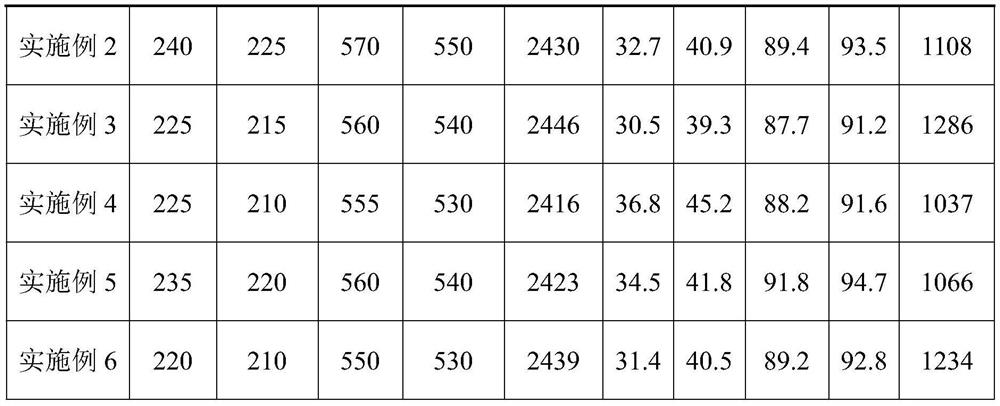

Method used

Image

Examples

preparation example Construction

[0034] In the present invention, the preparation method of the modified machine-made sand dust collecting stone powder comprises the following steps:

[0035] (1) Mix the co-solvent with water to obtain a mixed solution;

[0036] (2) Spray the mixed solution on the surface of the machine-made sand dust-collecting stone powder, mix it, then age, dry, and ball mill to obtain the modified machine-made sand dust-collecting stone powder.

[0037]In the present invention, the co-solvent is a mixture of triisopropanolamine and triethanolamine; the mass ratio of triisopropanolamine and triethanolamine is preferably 2 to 3:1, more preferably 2.5:1; The dosage of the above-mentioned co-solvent is preferably 0.15-0.20% of the dosage of the dust-collecting stone powder of the machine-made sand.

[0038] In the present invention, the machine-made dust-collecting stone powder is preferably one or more of limestone powder, marble powder, granite stone powder, basalt stone powder, and quartz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| methylene blue value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com