Coating aluminum foil as well as preparation method and application thereof

A technology of coating and aluminum foil, which is applied in the field of coated aluminum foil and its preparation, can solve the problems of limited filtering effect of the filter, increase the volume of the air conditioner, affect the heat exchange effect, etc., achieve long-term stable heat exchange performance, reduce oily smoke and Effect of dust adhesion and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

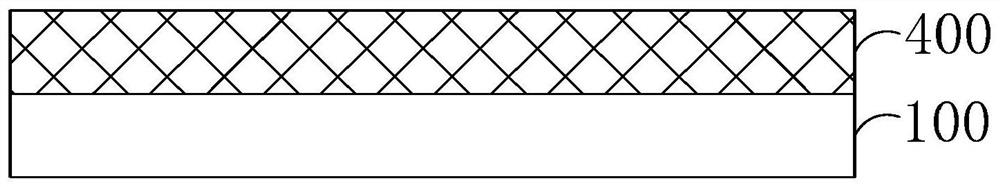

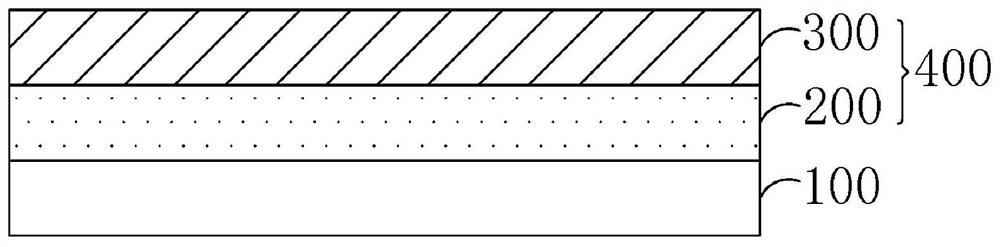

[0077] According to an embodiment of the present invention, the method for preparing a coated aluminum foil includes the following steps: coating paint on at least one surface of an aluminum foil substrate to form a functional coating to obtain a coated aluminum foil.

[0078] According to an embodiment of the present invention, when the functional coating contains a hydrophilic layer and an anti-corrosion layer, when preparing the coated aluminum foil, the anti-corrosion layer coating is first primed to form an anti-corrosion layer, and then the hydrophilic layer coating is topcoated to form a hydrophilic layer. layer to produce a coated aluminum foil. In some embodiments of the present invention, the preparation method of the coated aluminum foil comprises the following steps: 1) coating an anti-corrosion coating on at least one surface of the aluminum foil substrate, curing to form an anti-corrosion layer; The surface away from the aluminum foil base material is coated with...

Embodiment 1

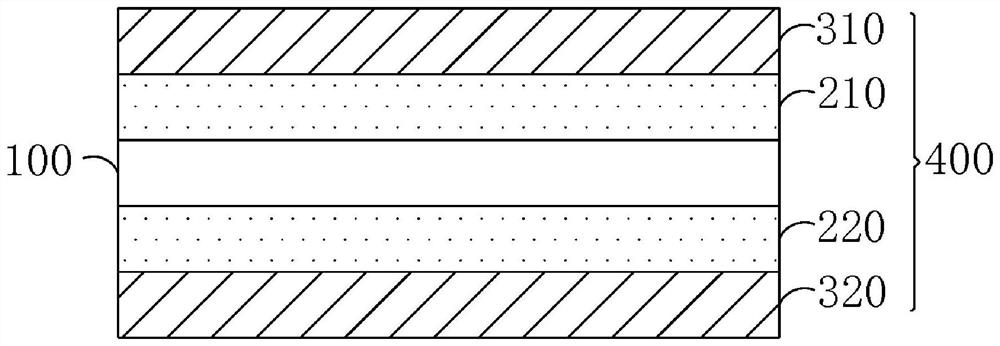

[0091] refer to image 3 , the structure and composition of the coated aluminum foil in this example are as follows:

[0092] The first hydrophilic layer: the amount of coating film is 0.5g / m 2 The coating of the first hydrophilic layer consists of 8wt% hydroxyl acrylic acid monomer, 28wt% carboxyl acrylic acid monomer, 9wt% amido acrylic acid monomer, 8wt% epoxy acrylic acid monomer, 2wt% sodium persulfate, 1wt% ten Sodium dialkylbenzenesulfonate and the remainder of water;

[0093] The first anti-corrosion layer: the amount of coating film is 0.8g / m 2 ; The coating of the first anticorrosion layer consists of 12wt% acrylic resin, 3.2wt% ethylene glycol butyl ether and the water of the remainder;

[0094] Aluminum foil substrate;

[0095] The second anti-corrosion layer: the amount of coating film is 0.8g / m 2 ; The coating of the second anti-corrosion layer consists of 12wt% acrylic resin, 3.2wt% ethylene glycol butyl ether and the water of the remainder;

[0096] The s...

Embodiment 2

[0103] refer to image 3 , the structure and composition of the coated aluminum foil in this example are as follows:

[0104] The first hydrophilic layer: the amount of coating film is 0.8g / m 2 The coating of the first hydrophilic layer consists of 8wt% hydroxyl acrylic acid monomer, 28wt% carboxyl acrylic acid monomer, 9wt% amido acrylic acid monomer, 8wt% epoxy acrylic acid monomer, 2wt% sodium persulfate, 1wt% ten Sodium dialkylbenzenesulfonate and the remainder of water;

[0105] The first anti-corrosion layer: the amount of coating film is 0.5g / m 2 ; The coating of the first anticorrosion layer consists of 12wt% acrylic resin, 3.2wt% ethylene glycol butyl ether and the water of the remainder;

[0106] Aluminum foil substrate;

[0107] The second anti-corrosion layer: the amount of coating film is 0.5g / m 2 ; The coating of the second anti-corrosion layer consists of 12wt% acrylic resin, 3.2wt% ethylene glycol butyl ether and the water of the remainder;

[0108] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com