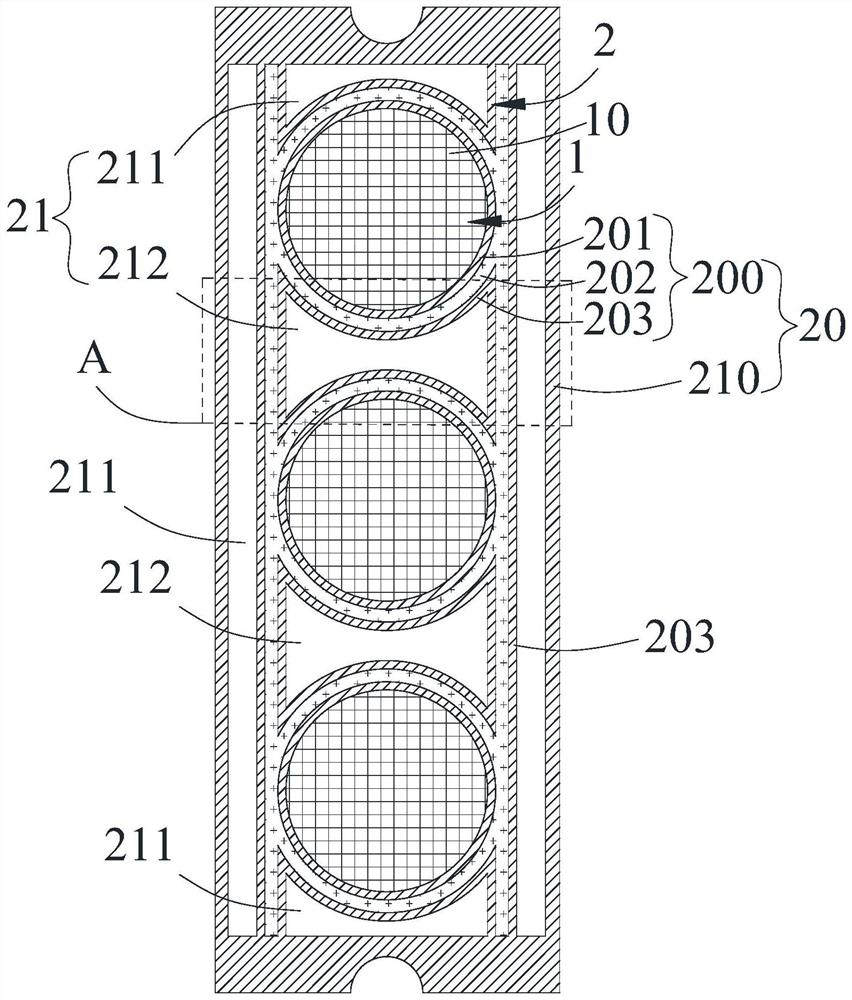

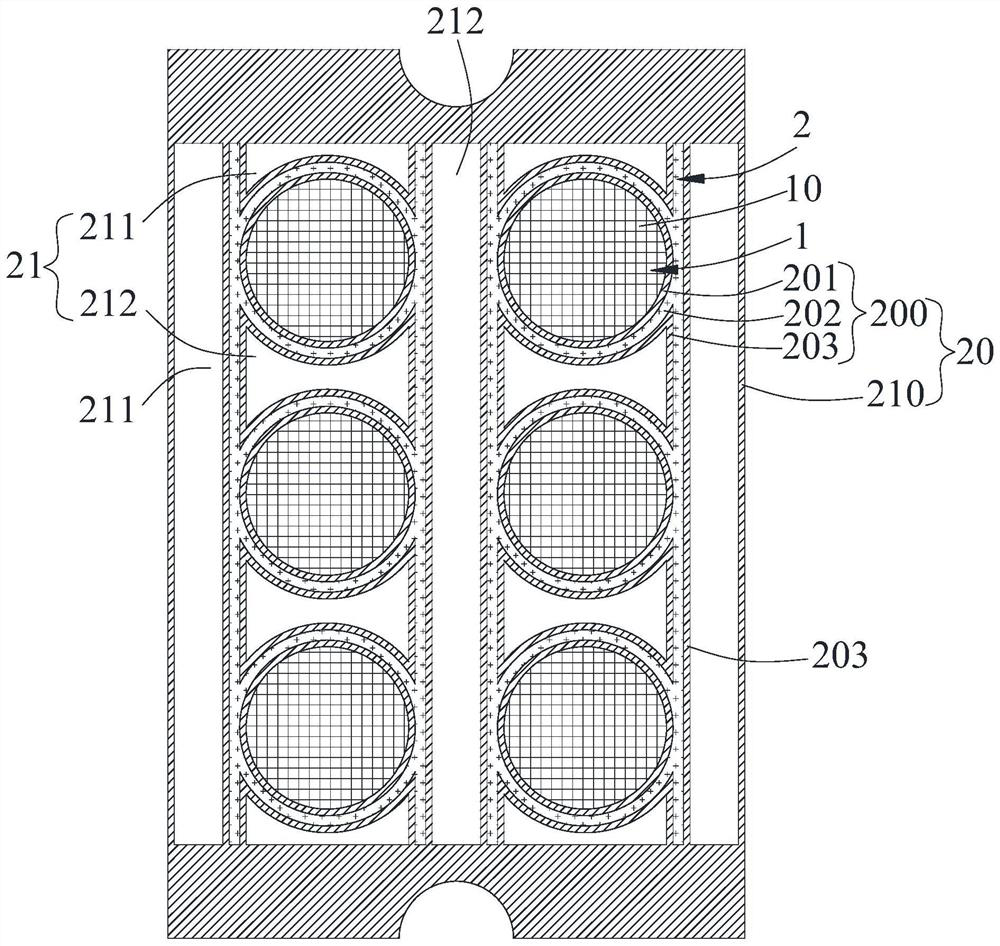

Mask plate and mask assembly

A technology of mask plate and evaporation area, applied in the field of mask plate and mask assembly, can solve the problem of affecting evaporation effect, precision metal mask plate cannot be flattened by magnetic field adsorption, and precision metal mask plate is prone to wrinkles and other problems, to achieve the effect of improving evaporation yield, uniform strain, and not easy to wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

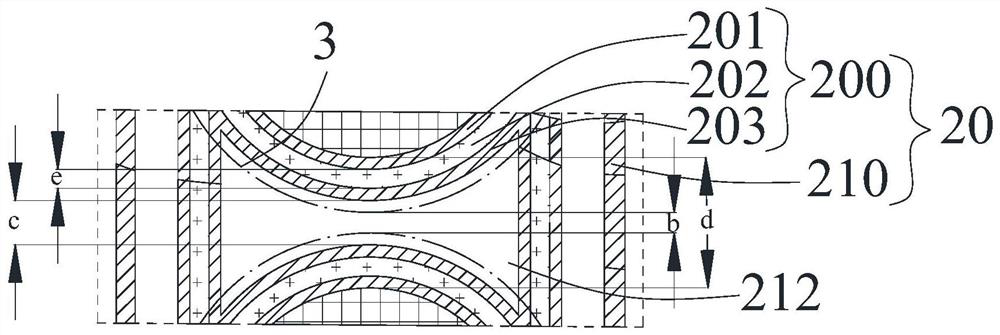

[0036] The features and exemplary embodiments of the various aspects of the present application will be described in detail below. Many specific details are proposed in the following detailed description to provide a comprehensive understanding of the present application. However, it is apparent to those skilled in the art that the present application can be implemented in the case where some details do not require these specific details. The description of the embodiments is merely a better understanding of the present application only for examples of the examples of the present application.

[0037] It should be noted that in this article, a relationship term such as the first and second, etc. is only used to distinguish an entity or operation with another entity or an operational zone, without having to require or imply these entities or operations. There is any such practical relationship or order. Moreover, the term "comprising", "comprising" or any other variable is intended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com