Fishing port wharf structure suitable for different water levels and using method of fishing port wharf structure

A fishing port and wharf technology, applied in the field of port water conservancy projects, can solve the problems of high rental maintenance and use costs, unfavorable modular production and complex component structures, etc., achieve low rental maintenance and use costs, and facilitate modular production and manufacturing. The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

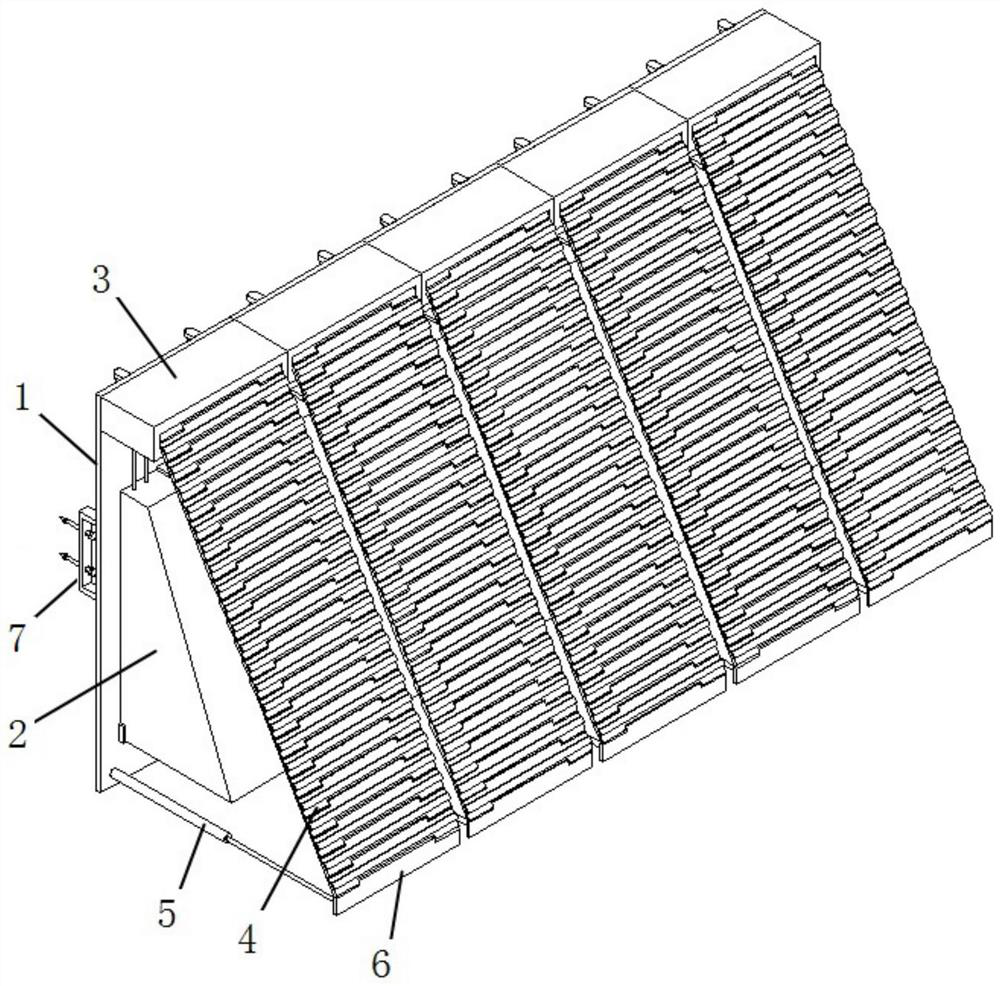

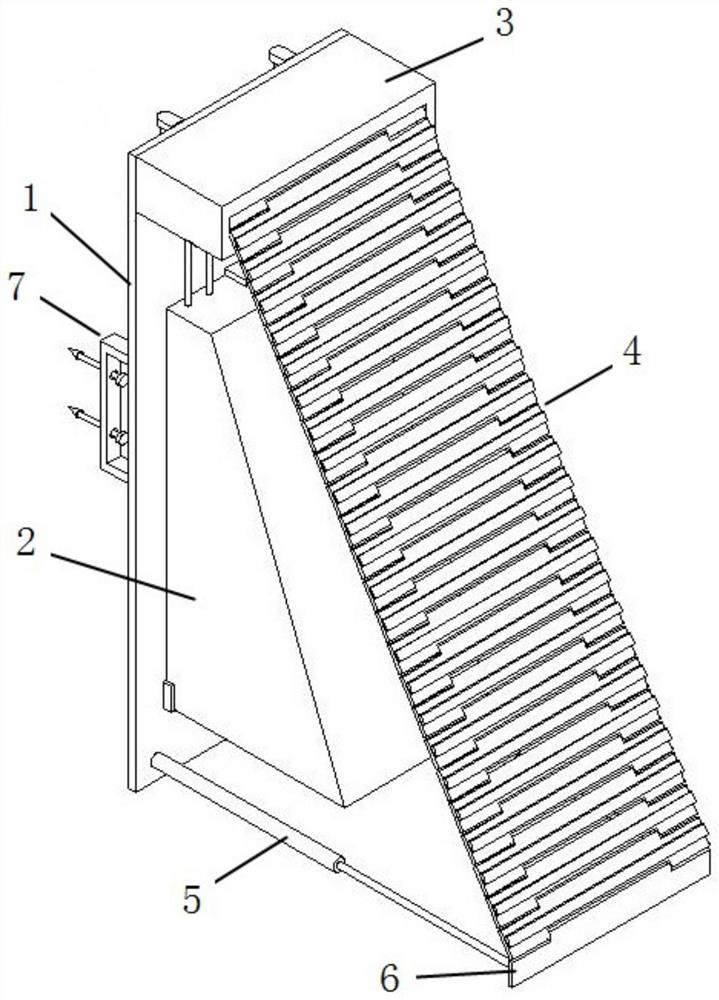

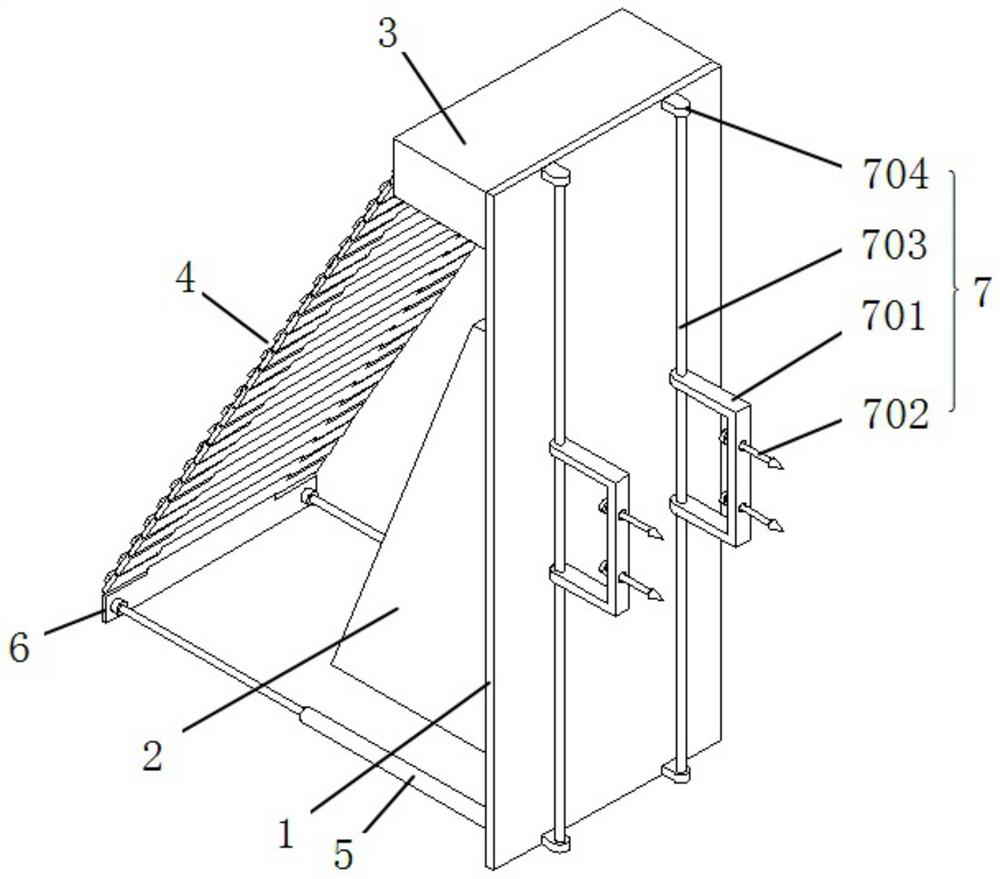

[0034] see Figure 1-6 As shown, this embodiment is a fishing port wharf structure suitable for different water levels. The fishing port wharf structure includes several modular docking units. Type docking plate 4, telescopic rod 5, limit base plate 6 and self-adjusting guiding mechanism 7.

[0035] In this embodiment, a floating airbag 2 is connected to the outer middle part of the support vertical plate 1, and a storage box 3 is fixed on the outer top of the support vertical plate 1. The storage box 3 is provided with a storage area 301 for installing the rolling assembly and a storage area 301 for installing The air pump installation area 302 of the buoyancy adjustment air pump, the buoyancy adjustment air pump communicates with the floating air bag 2 through the air pipeline, and the reel of the winding and unwinding assembly is wound and connected with a roller shutter type docking plate 4 . The outer end of the roller shutter-type docking plate 4 is connected with a lim...

Embodiment 2

[0043] The structure and application of this embodiment are basically the same as those of Embodiment 1, the difference being that the telescopic rod 5 is an electric telescopic rod.

Embodiment 3

[0045] The structure and application of this embodiment are basically the same as those of the first embodiment, the difference being that the support vertical board 1 is fixedly connected to the floating airbag 2 by binding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com