Stepped grading spillway with energy dissipation effect

A ladder-shaped, spillway technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as difficulty in achieving high energy dissipation effect, unstable water jump state of stilling pools, and lengthening of stilling pools. Achieve the effect of overcoming disadvantages and limitations of use conditions, structural safety and adaptability, and improving energy dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

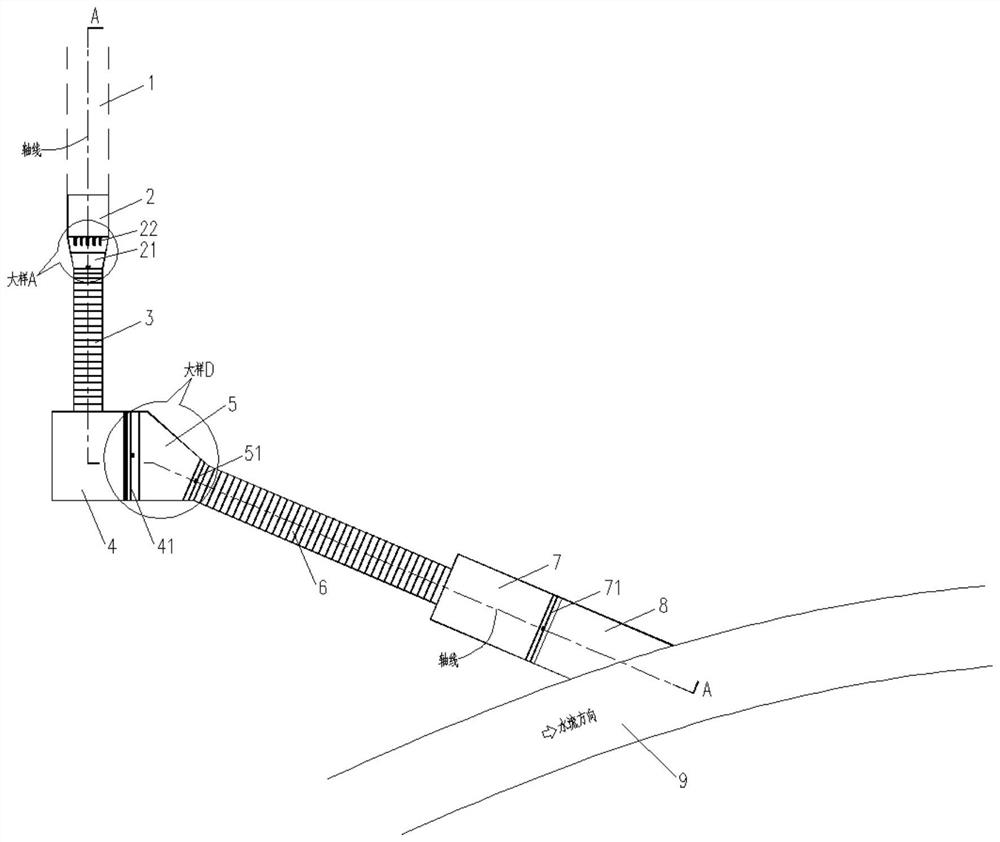

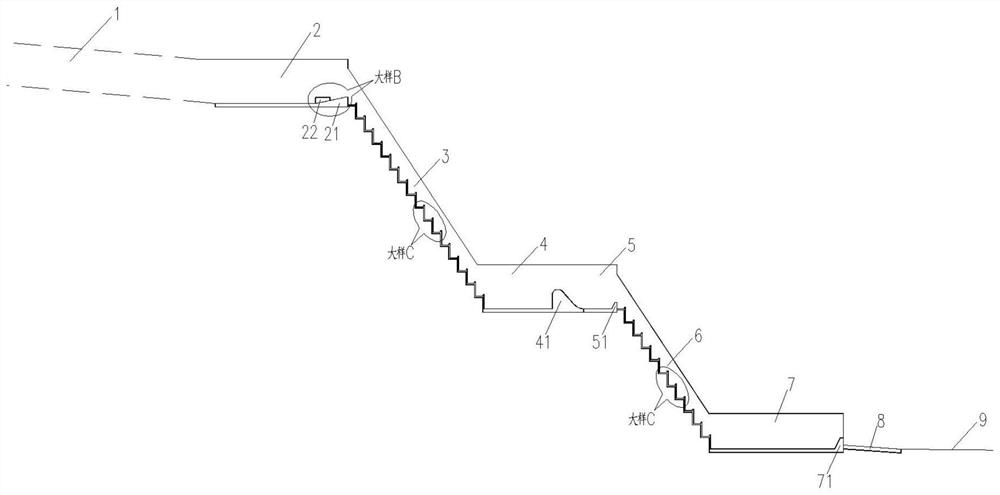

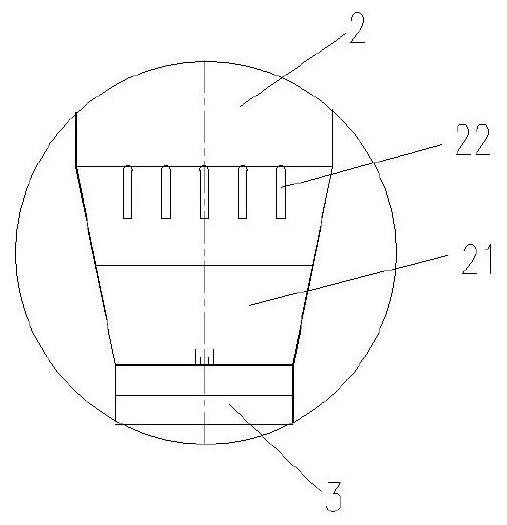

[0031] Such as Figure 1 to Figure 6 As shown, a ladder-shaped graded spillway with energy dissipation effect according to the present invention includes a first-level stilling basin 2, a first-level steep groove 3, a second-level stilling basin 4, and a third-level stilling basin arranged in sequence from upstream to downstream Stilling basin 5, second-level steep groove 6, fourth-level stilling basin 7 and sea diffuser 8, the upstream side of the first-level stilling basin 2 is connected to the flood discharge tunnel 1, and the downstream side of the said sea diffuser 8 is connected to the original The river course 9 connects smoothly. When in use, the transverse direction of the first-level stilling pool 2, the first-level steep groove 3, the second-level stilling pool 4, the third-level stilling pool 5, the second-level steep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com