Gas well gas and speed increasing and water atomizing device

A technology of water atomization and gas well, applied in the direction of injection device, injection device, liquid injection device, etc., can solve the problems of low recovery rate, small liquid drainage capacity, high safety and reliability requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

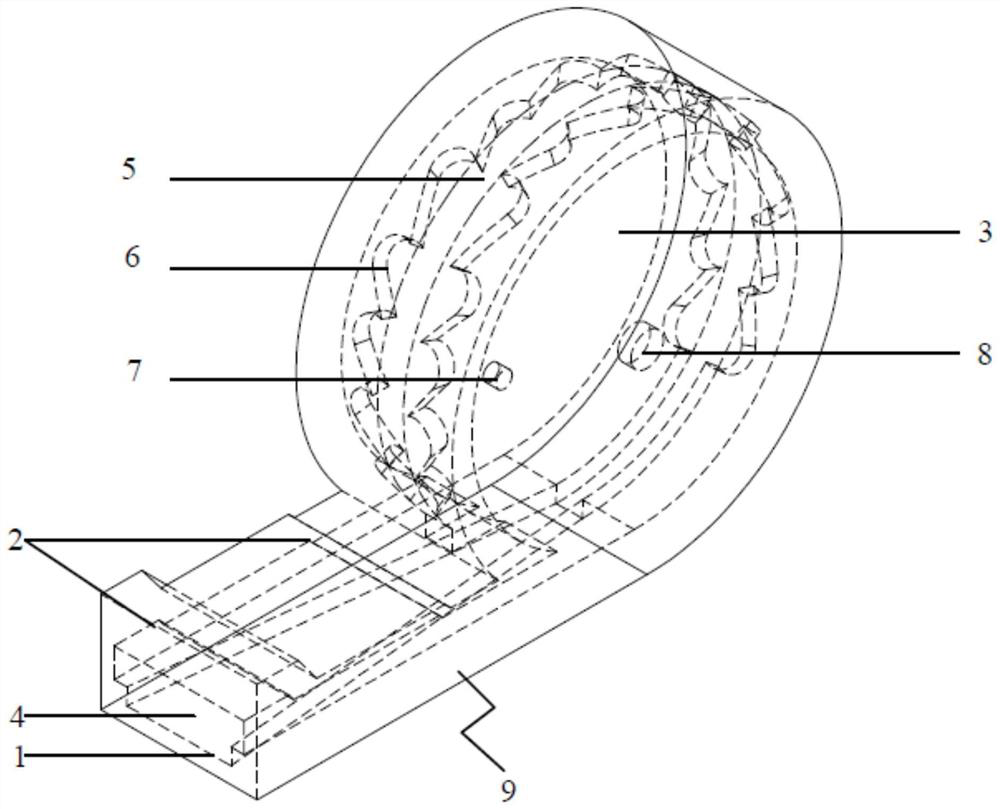

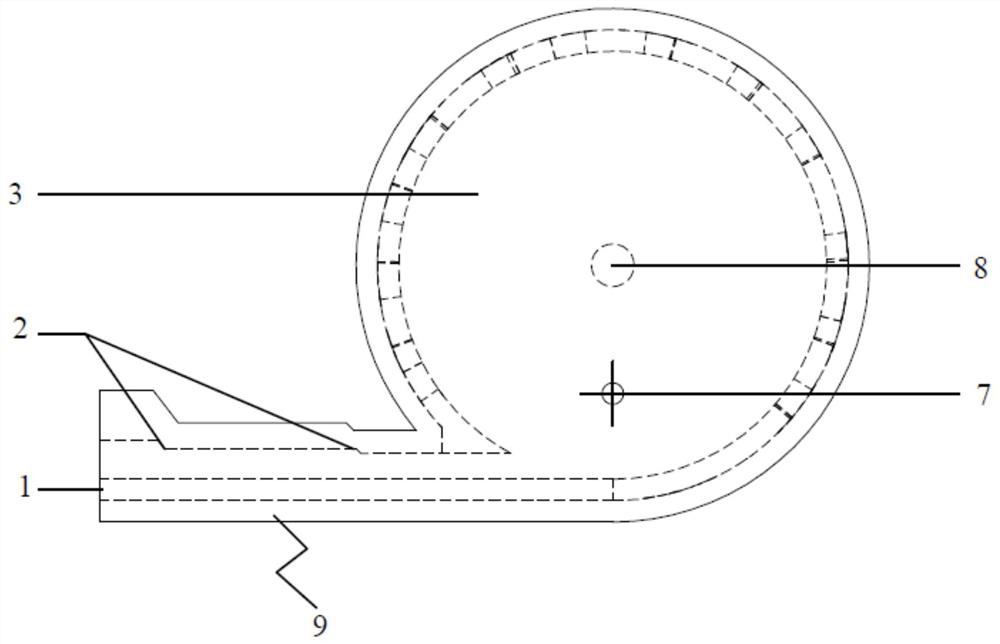

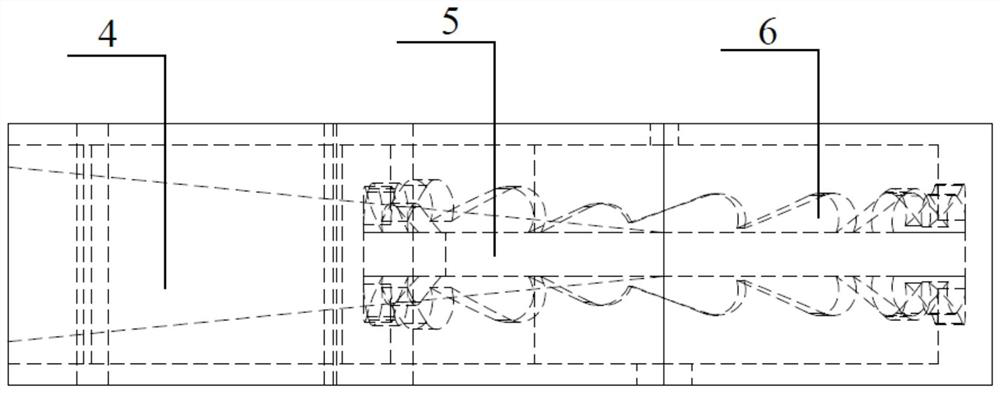

[0017] Such as figure 1 As shown, the embodiment of the present invention provides a gas well gas-increasing speed-up and water atomization device, which may include: a spray chamber inlet 1, an inlet variable diameter pre-acceleration chamber 2, an annular speed-up chamber 3, and a tapered diameter pre-acceleration flow channel 4 , acceleration channel main channel 5, variable diameter speed-up channel 6, atomization outlet 7, air outlet 8, linear pre-acceleration chamber 9; the whole device consists of a linear pre-acceleration chamber 9 and an annular speed-up chamber 3 tangential to it Composition, the inlet 1 of the spray chamber is the direction of fluid inflow, the atomization outlet 7 and the air outlet 8 are the direction of fluid outflow, the atomization outlet 7 and the air outlet 8 are respectively arranged on the two sides of the annular sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap