Medicament taking and automatic weighing device

An automatic weighing and pharmaceutical technology, applied in the direction of measuring device, weighing, packaging, etc., can solve the problems of difficult to control the amount of medicine, increase working time, trouble, etc., achieve stable material state, ensure weighing accuracy, and avoid drugs. stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

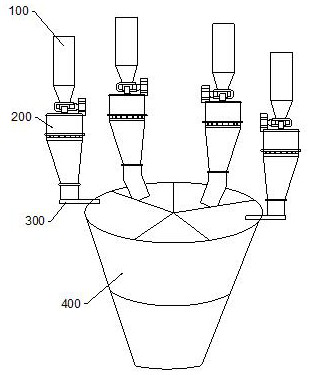

[0034] to combine figure 1 , a medicine taking and automatic weighing device, including a feeding mechanism 100, a weighing mechanism 200 and a re-inspection bin 400 connected in sequence, the re-inspection bin 400 is divided into several sub-bins by partitions, the Each of the several sub-bins corresponds to a feeding mechanism 100. Through multiple feeding mechanisms 100 corresponding to the sub-bins, multi-station batching and weighing can be realized, and the vacuum feeder absorbs the raw materials in the bin. It is transported to the feeding pipe 1 of the feeding mechanism 100. According to the physical properties of the medicine, a variety of suitable stirring and arching devices can be installed in the feeding pipe to prevent the material from arching. After that, the medicine is bagged or transported to the next station.

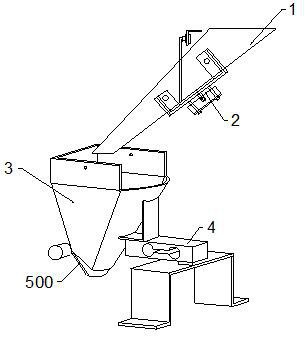

[0035] to combine figure 2 , the feeding mechanism 100 includes a feed pipe 1 and a vibrator 2 arranged on the feed pipe 1 to prevent the retenti...

Embodiment 2

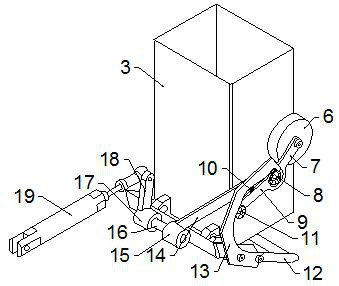

[0043] to combine Figure 5 and Figure 6 , the difference from embodiment 1 is that the blanking assembly includes a bull gear and a pinion connected by a synchronous belt, the pinion is arranged on the output shaft of the stepping motor, and the outer circumference of the bull gear It is meshed with the synchronous belt, and the axial surface of the large gear is provided with a number of evenly distributed guide rods fixedly connected with the inner wall of the large gear. The central part of the axial surface of the large gear is provided with a discharge hole. The end of the guide rod away from the inner wall of the large gear is fixedly connected with the outer periphery of the discharge hole.

[0044] The guide rod is provided with a guide groove extending along the direction of the guide rod, a slide pin is slidably connected in the guide groove, and the bottom end of the slide pin is connected with a fan-shaped plate arranged at the bottom of the discharge hole. Whe...

Embodiment 3

[0048] to combine Figure 7 , a medicine taking and automatic weighing device, including a feeding mechanism 100, a weighing mechanism 200 and a re-inspection bin 400 connected in sequence, the re-inspection bin 400 is divided into several sub-bins by partitions, the The outlet end of the blanking assembly 500 at the bottom of the weighing mechanism 200 transports the medicine to the sub-bin through the conveyor 300, and each sub-bin of the plurality of sub-bins corresponds to a feeding mechanism 100.

[0049] The vacuum feeder absorbs the raw materials in the silo and transports them to the feeding mechanism 100. After the feeding mechanism transports the materials to the weighing mechanism for weighing, the materials are transported to the conveyor through the blanking component. The controller according to the weighing The quality feedback of the mechanism, if the material is discharged through the blanking component at a high speed, it is easy to cause material blockage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com