Optical mirror surface online detection method and detection device

An optical mirror and detection device technology, applied in the field of laser detection, can solve the problems affecting the work and application of lasers, low work efficiency, high maintenance cost, etc., and achieve the effect of easy fine detection and analysis, strong applicability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

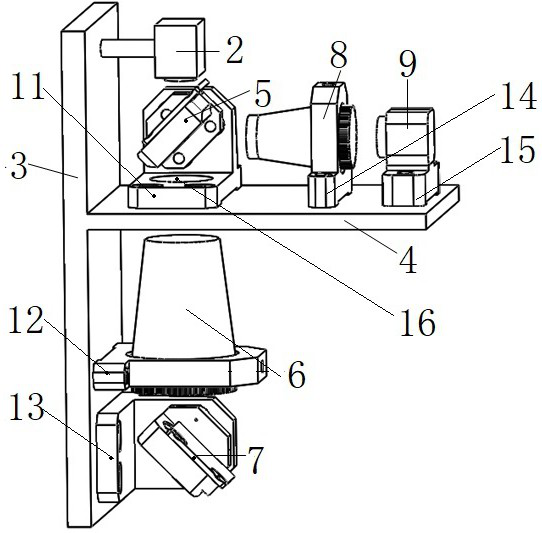

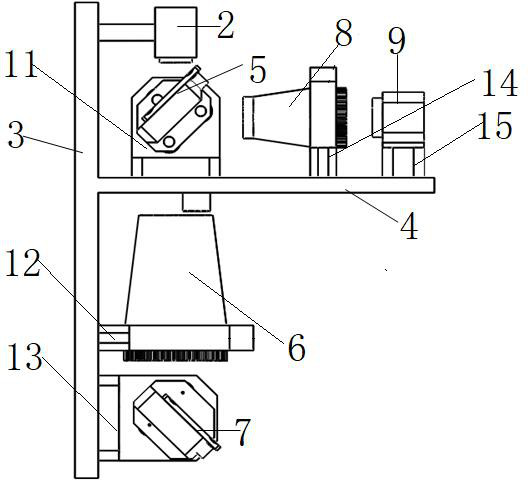

Image

Examples

Embodiment Construction

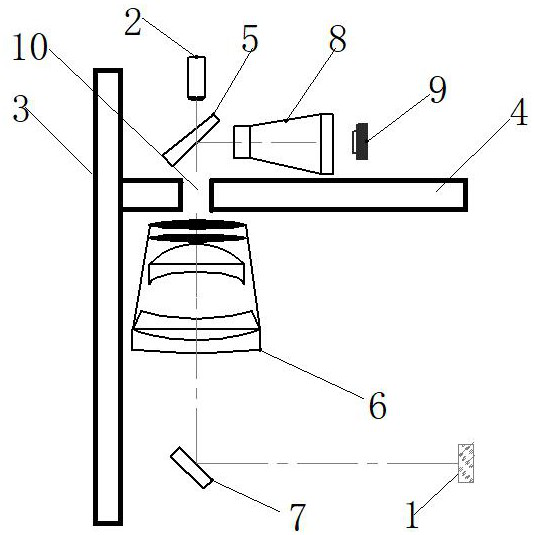

[0025] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

[0026] like image 3 As shown, a kind of optical mirror online detection method provided by the present invention adopts confocal detection method, comprising the following steps:

[0027] S01. Adopt the indicator light source with two modes of thin beam and large spot, adjust the indicator light source to the thin beam mode, take the indicator light emitted by the indicator light source as the reference light, and the incident light path of the indicator light source passes through the beam splitter in sequence before reaching the optical mirror And the zoom lens group, the optical path of the indicator light source coincides with the main optical axis of the zoom lens group; the reflector reflects the incident light path of the indicat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap