Defect detection system and method for thin film material

A technology for defect detection and thin film materials, which is applied in the field of defect detection systems for thin film materials, can solve the problems of poor detection effect, poor generalization ability, and low detection accuracy, so as to improve the detection effect and reduce the probability of missed detection and false detection , Improve the effect of defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

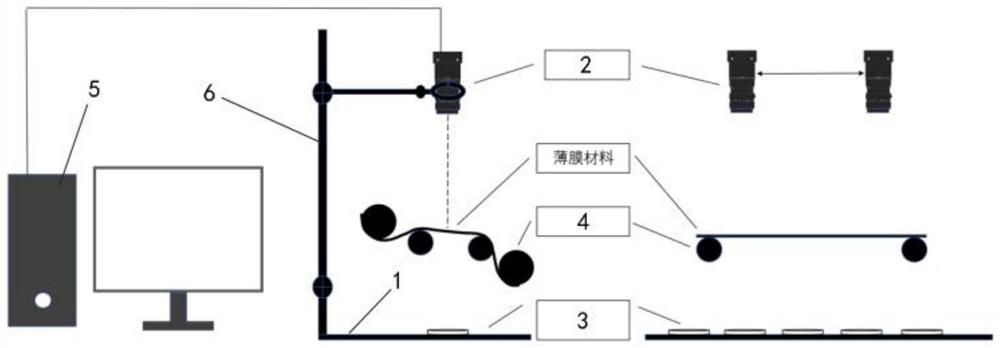

[0067] Such as figure 1 As shown, a defect detection system for thin film materials described in this embodiment includes an image acquisition platform 1, a line scan camera 2, a light source 3, a conveying line 4 for conveying the film, a detection computer 5 and a mounting frame 6;

[0068] Among them, the light source 3 is laid on the image acquisition platform 1, and emits high-brightness line light from bottom to top; the line array camera 2 is fixed above the light source 3 through the mounting frame 6; the transmission line 4 is installed between the line array camera 2 and the light source 3, It extends along the laying direction of the light source 3; the detection computer 5 is connected with the line scan camera 2.

[0069] Specifically, in the above,

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com