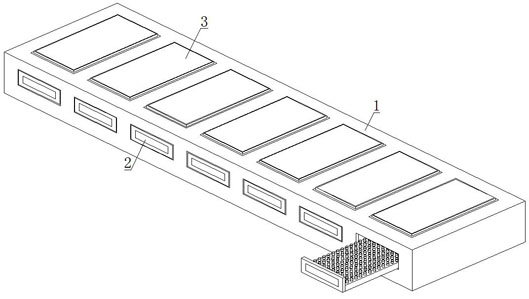

Device and method for testing current-carrying capacity of copper bar

A testing device and flow technology, which is applied to the measuring device, the housing of the measuring device, the parts of the electrical measuring instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a test method of a test device for the carrying capacity of a copper bar, comprising the following steps:

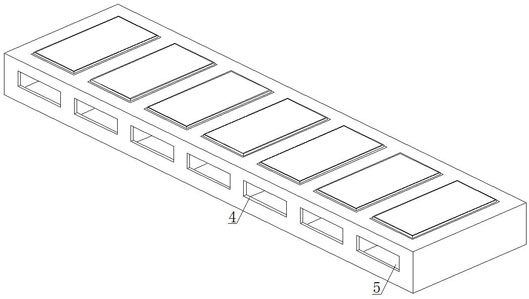

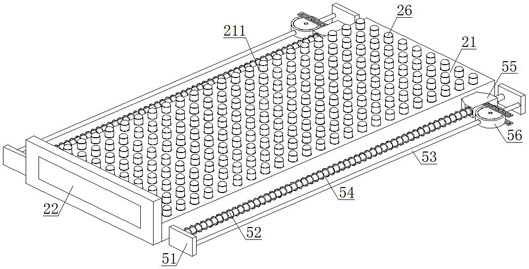

[0050] Step 1: start the drive shaft 564, the disc body 561 makes the top pressure small block 565 drive the limit bar 553 to move to one side, the trapezoidal slider 55 drives the external baffle 22 to disengage from the opening 4, and the supporting test plate 2 as a whole moves from Pulled out from the test cavity 5, the adjusting plate 56 can move along with the trapezoidal slider 55, when the external baffle 22 is loosened, the supporting test plate 2 returns to the test cavity 5 as a whole;

[0051] Step 2: When the supporting test board 2 is pulled out from the test cavity 5, place the copper bar test piece 6 on the upper end of the supporting board 21, start the driving gear 2412, and the two sets of adjusting gears 2413 move closer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com