Wireless electric energy data hybrid transmission rotary connector

A rotary connector and hybrid transmission technology, used in flexible/rotatable wire connectors, connections, circuits, etc., can solve problems such as poor reliability, discontinuous contact impedance, data loss, etc., to ensure high-power electrical energy and data stability. No loss, the effect of shortening the axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

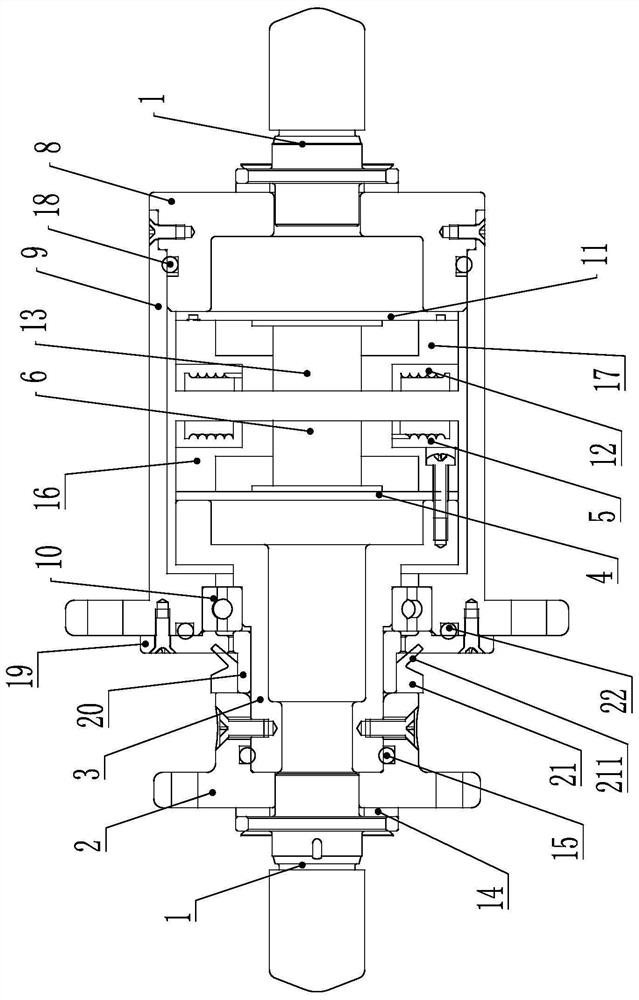

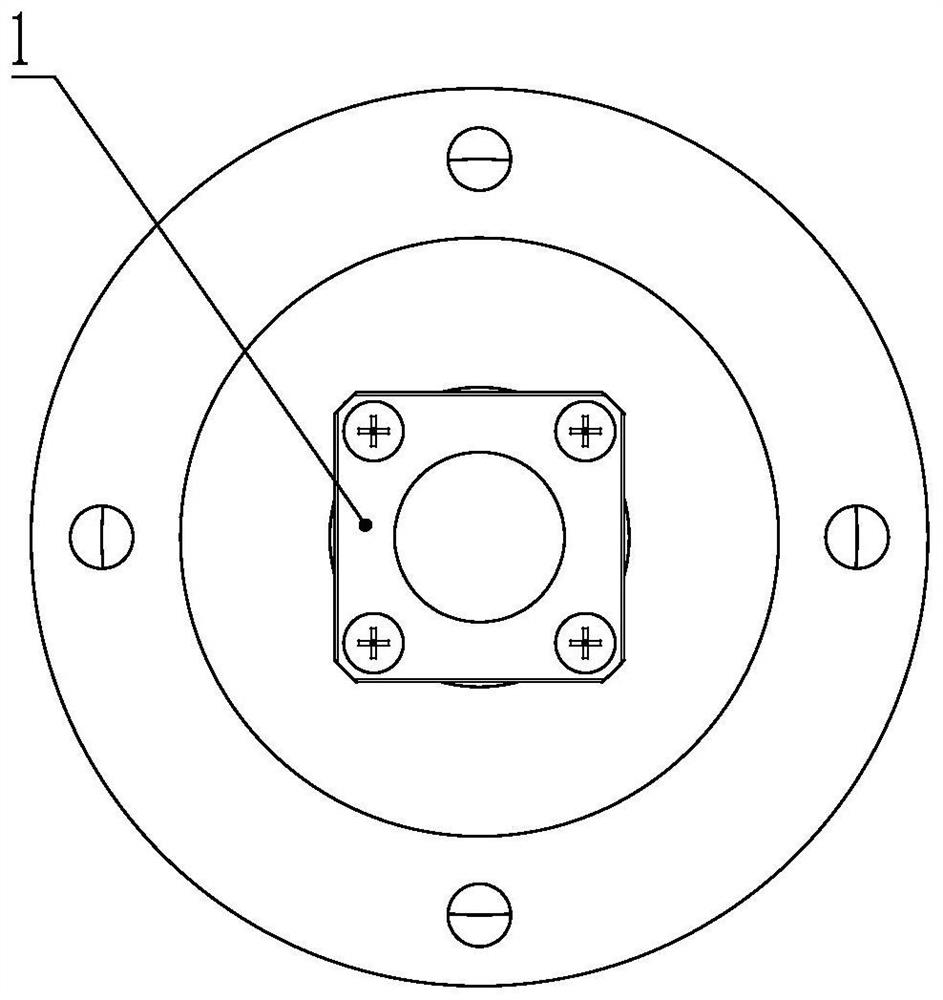

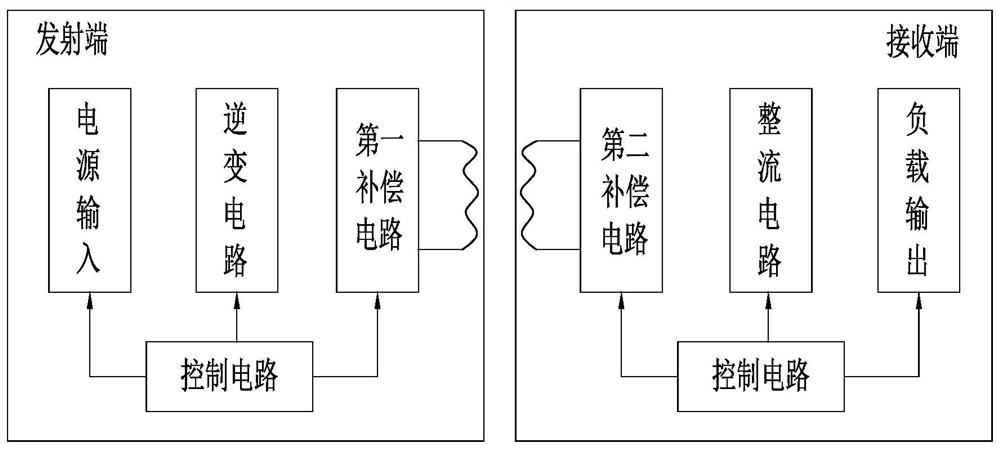

[0040] see Figure 1 to Figure 5 , a wireless power data mixed transmission rotary connector, including a rotor part and a stator part, the rotor part includes a rotor end interface connector 1, a flange 2, a rotating shaft 3, a rotor end circuit board 4, an electric energy transmitting coil 5 and a rotor The end antenna module 6 , the stator part includes a stator end interface connector 7 , a tail end cover 8 , an outer shell 9 , a bearing 10 , a stator end circuit board 11 , a power receiving coil 12 and a stator end antenna module 13 . For ease of description, it is defined that the installation position of the rotor-end interface connector is the rear end of the rotor component, and the installation position of the stator-end interface connector is the rear end of the stator component.

[0041] The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com