Magnetron sputtering banknote printing plate coating equipment

A technology of magnetron sputtering and coating equipment, used in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problem of low qualification rate of banknote printing plate coating, avoid disturbance and ensure cleanliness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

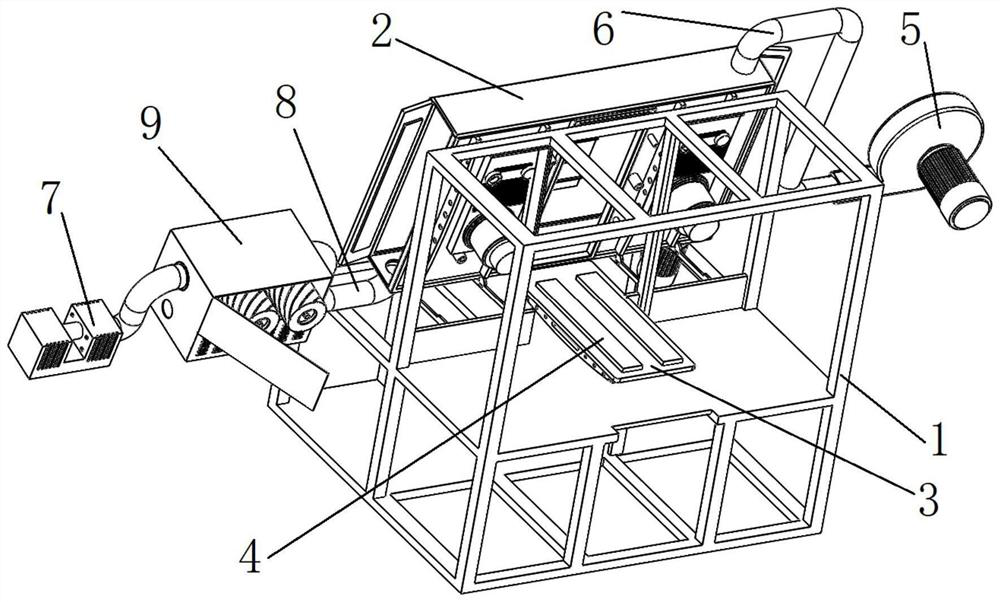

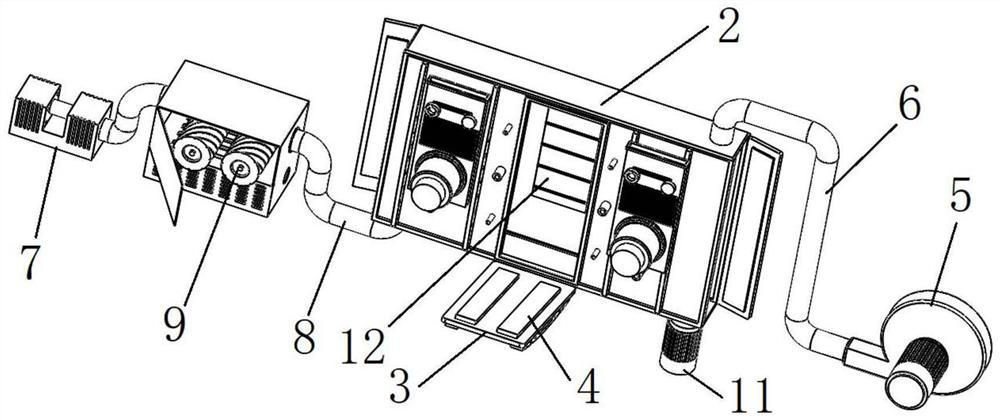

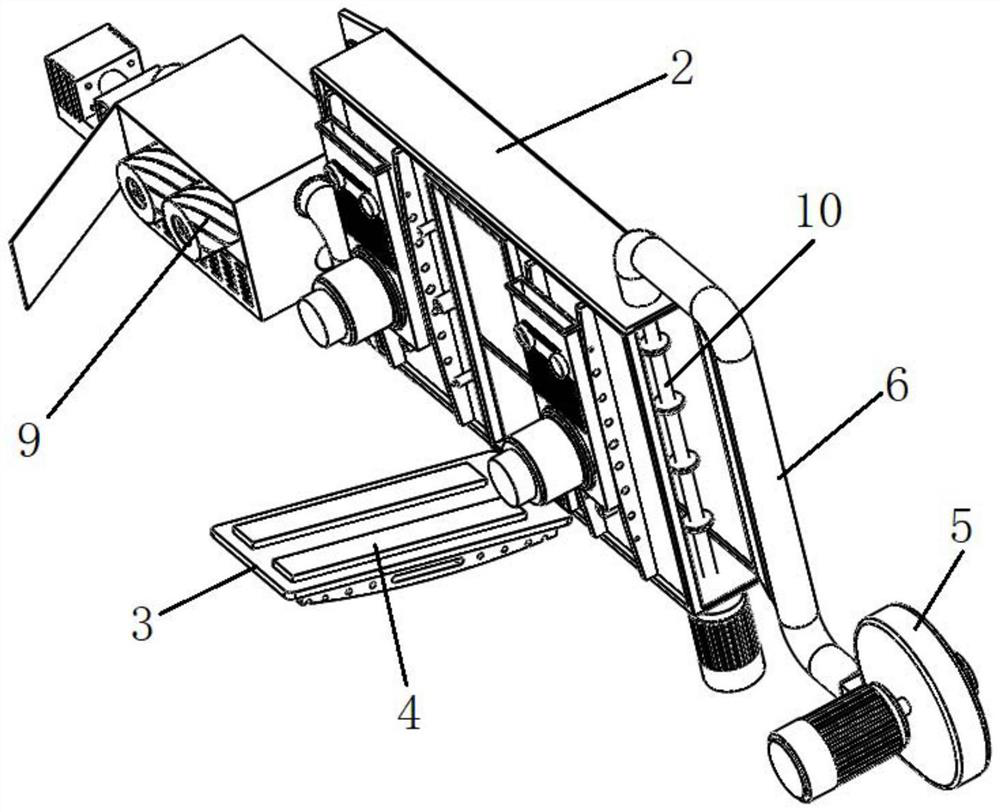

[0033] Such as Figure 1 to Figure 3 Shown is a specific implementation of a magnetron sputtering banknote printing plate coating device provided in this embodiment, including: a mounting bracket 1 , and a vacuum chamber 2 fixedly installed on the mounting bracket 1 . The left and right sides of the vacuum chamber 2 are respectively equipped with an air pumping assembly and an inflating assembly, and a winding rod 10 is installed on the right side of the inner cavity of the vacuum chamber 2 to rotate. For the convenience of observing the internal structure of the vacuum chamber 2, Figure 1 to Figure 3 The sidewalls on the left and right sides of the medium vacuum chamber are all open, and the carrier plate 3 on the vacuum chamber is in a ready state. During the coating process, the side walls on the left and right sides of the vacuum chamber are completely sealed and connected with the vacuum chamber body, and the bearing plate is in the working state, and is sealed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com