Adjustable ejector and high-pressure gas well and low-pressure gas well simultaneous recovery gas-liquid mixed transportation system

An adjustable and ejector technology, which is applied in the pipeline system, gas/liquid distribution and storage, mixer, etc., can solve the problems of nozzle influence, gas well pressure reduction, and restricting the scope of application of the process, so as to simplify the gas gathering process, Realize the effect of gathering and transportation process and efficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

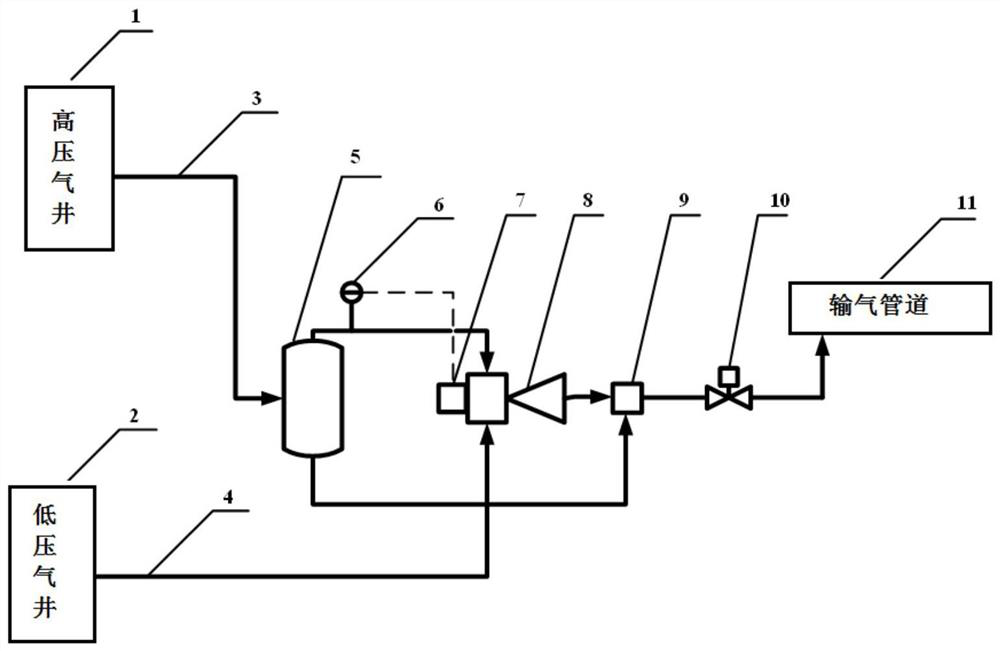

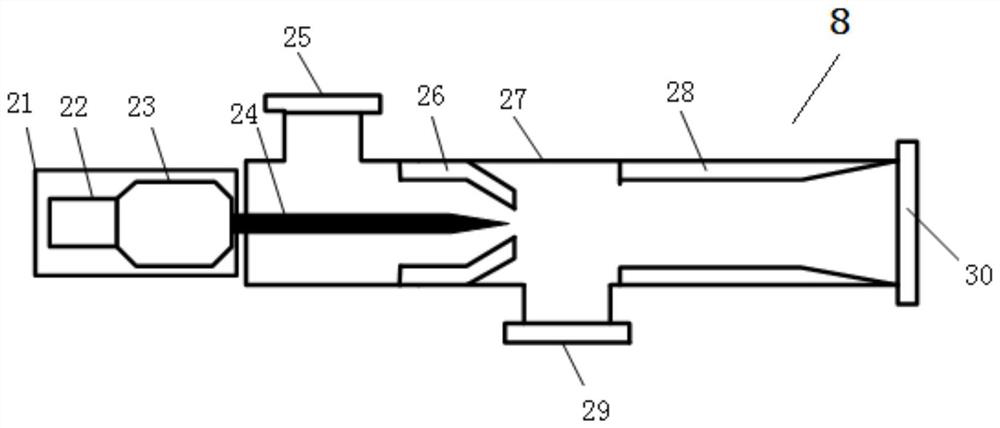

[0059] like figure 1 and figure 2 As shown, the present embodiment proposes an adjustable ejector 8, which mainly includes: a mixing tube 28, one end of which is provided with a mixer outlet 30; a sleeve 27 connected to the other end of the mixing tube 28, the The side of sleeve pipe 27 is provided with low-pressure air inlet 29; Regulator chamber is provided with nozzle 26, adjustment cone 24 and high-pressure air inlet 25, and described nozzle 26 is connected with described sleeve pipe 27, and described adjustment cone 24 is connected with The nozzles 26 are arranged cooperatively for adjusting the pressure of the air flow passing through the nozzles 26 . As shown in the figure, the front end of the adjusting cone 24 is in the shape of a slender cone.

[0060] The adjustable injector 8 also includes: a controller 21, arranged at the end of the adjustable injector 8, including a model calculation module 22 and a stepper motor 23, the model calculation module 22 is electric...

Embodiment 2

[0062] like figure 1 and figure 2 As shown, the present embodiment proposes a high-pressure and low-pressure gas well co-production gas-liquid mixed delivery system, including: an adjustable ejector 8; Gas port 29; high-pressure gas-liquid separator 5 is provided with inlet, gas phase outlet and liquid phase outlet, gas phase outlet is connected to the high pressure air inlet 25 of adjustable ejector 8 through pipeline, and pressure sensor 6 is arranged on gas phase outlet and high pressure On the pipeline between the air inlets 25; the gas-gathering pipeline 3 of the high-pressure gas well, one end is connected to the inlet of the high-pressure gas-liquid separator 5; the gas-liquid mixer 9 is arranged on the downstream of the adjustable injector 8, including gas phase inlet, liquid A phase inlet and a gas-liquid outlet, the gas phase inlet is connected to the gas outlet 30 of the mixer, and the liquid phase inlet is connected to the liquid phase outlet.

[0063] The high-...

Embodiment 3

[0066] In this embodiment, the system of the present invention is adopted to connect the newly developed wells of the gas field in parallel to the gas gathering pipelines of the existing gas wells, so as to realize the simultaneous exploitation of high pressure new wells and low pressure old wells, and transport them to the gas field gas gathering station by means of gas-liquid mixed transportation. After adopting the system of this embodiment, the effect is obvious. The output pressure of the new high-pressure well is 5 MPa, the flow rate is 100,000 m3 / day, the output pressure of the old low-pressure well is 2 MPa, and the gas volume is 10,000 m3 / day. Simultaneous production of high and low pressure gas wells can be realized , the production of high-pressure gas wells does not affect the production of low-pressure gas wells.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap