Manifold micro-column array flat plate heat exchanger

A technology of microcolumn array and heat exchanger, which is applied in the field of heat pipe of F28d15/02, can solve the main problems such as limited effect and unrealized optimization of manifold microchannel structure, so as to improve heat dissipation performance, strengthen overall heat transfer, improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

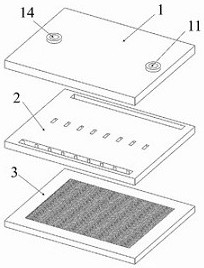

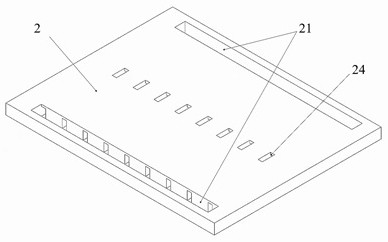

[0034] Figure 1-8 Disclosed is a manifold microcolumn array plate heat exchanger. Such as figure 1 As shown, the manifold microcolumn array flat plate heat exchanger is provided with fluid inlet and outlet layer 1, manifold diversion layer 2 and microcolumn array layer 3 in sequence from top to bottom, and the three-layer structure is combined to form a complete manifold microcolumn array heat exchanger. heater.

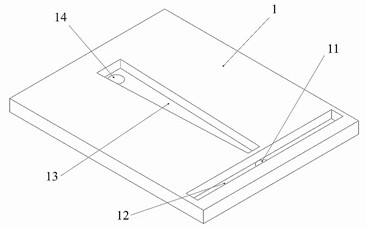

[0035] Such as figure 1 , 2 As shown, the fluid inlet and outlet layer 1 includes an upper face and a lower face, the upper face is provided with a fluid inlet 11 and a fluid outlet 14, the lower face is provided with a fluid inlet channel 12 and a fluid outlet channel 13, and the fluid inlet 11 It communicates with the fluid inlet channel 12, and the fluid outlet 14 communicates with the fluid outlet channel 13. The fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com