Hermetically sealed aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and capacitors, applied in capacitor terminals, capacitor parts, capacitor casings/packages, etc., can solve problems such as electrolyte leakage, capacitor failure, and decrease in bonding force, so as to prolong service life and improve air tightness. , the effect of saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

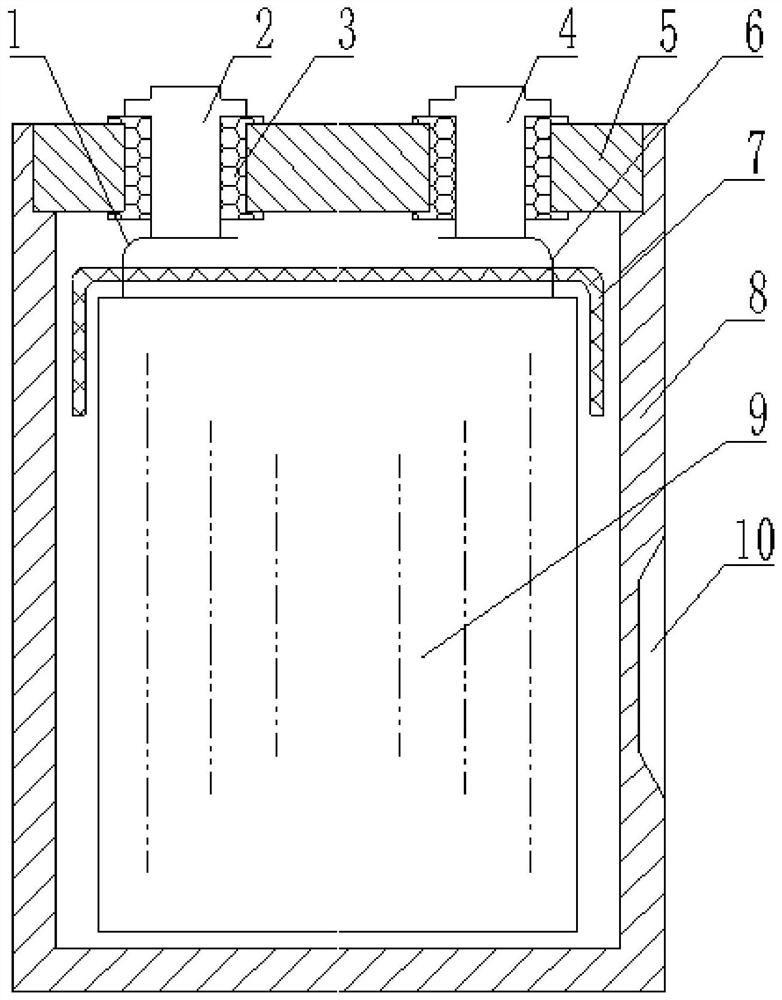

[0032] Such as figure 2 As shown, a cylindrical hermetic aluminum electrolytic capacitor is provided in this embodiment, comprising:

[0033] The circular cover plate 11 is composed of the metal cover plate 5, the positive terminal 1, the negative terminal 4 and the insulating ring 3 arranged between the positive terminal 1 and the negative terminal 4 and the metal cover 5. The insulating ring 3 is made of injection molding Forming, the material of the metal cover plate 5, the positive terminal 1 and the negative terminal 3 is high-purity aluminum, and the material of the insulating ring 3 is polyphenylene sulfide;

[0034] The positive lead-out bar 1 arranged on the capacitor core 9 with electrolyte attached passes through the heat shield 7 and connects with the positive lead-out end 1 by riveting, and the negative lead-out bar 6 arranged on the capacitor core 9 with electrolyte attached passes through the insulation cover 7 The heat shield 7 is connected to the negative po...

Embodiment 2

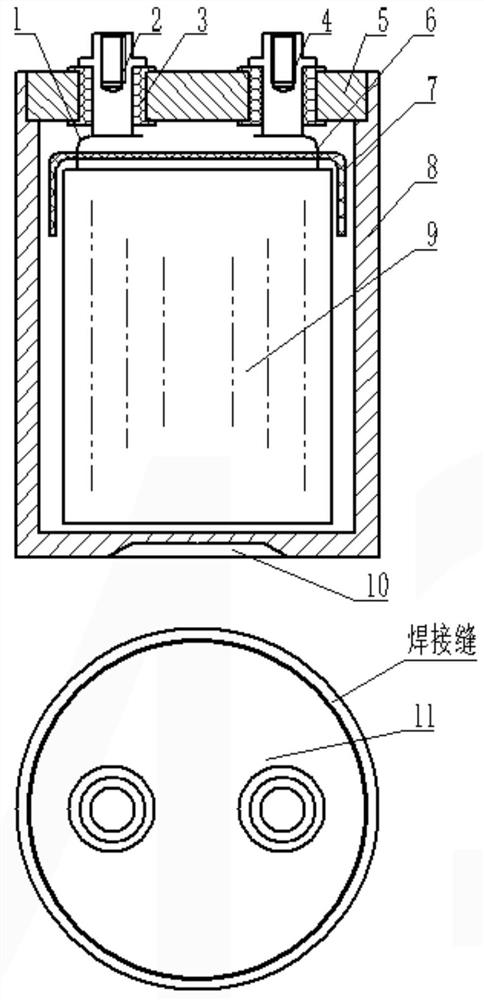

[0041] Such as image 3 As shown, a square hermetic aluminum electrolytic capacitor is provided in this embodiment, including:

[0042] The square cover plate 12 is composed of the metal cover plate 5, the positive terminal 1, the negative terminal 4 and the insulating ring 3 arranged between the positive terminal 1 and the negative terminal 4 and the metal cover 5, and the insulating ring 3 is molded , the material of the metal cover plate 5 is stainless steel, the material of the positive terminal 1 and the negative terminal 3 is high-purity aluminum, and the material of the insulating ring 3 is epoxy resin;

[0043] The positive lead-out bar 1 arranged on the capacitor core 9 with the electrolyte attached passes through the heat shield 7 and is connected to the positive lead-out end 1 by laser spot welding, and the negative lead-out bar 6 arranged on the capacitor core 9 with the electrolyte attached After passing through the heat shield 7, it is connected to the negative ...

Embodiment 3

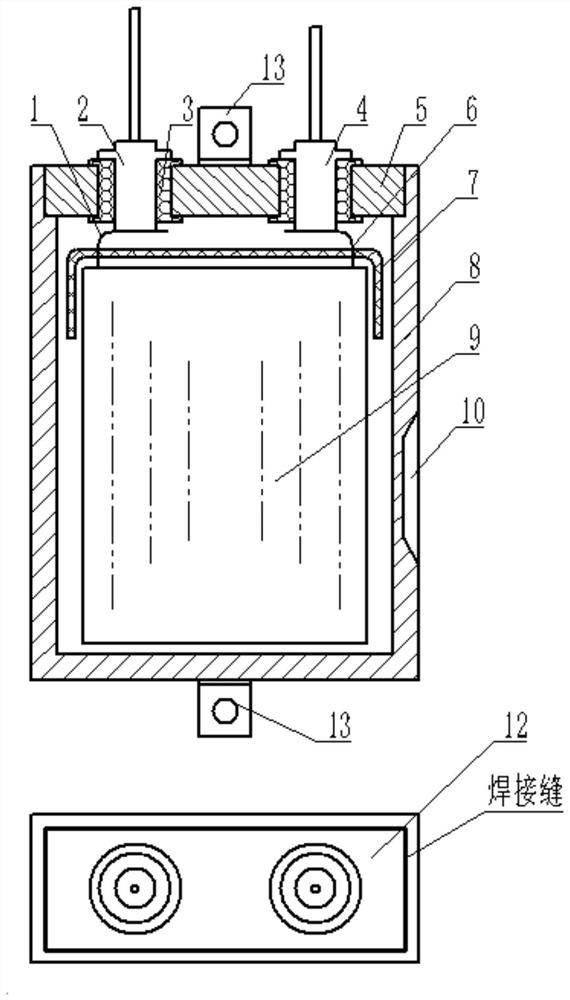

[0051] Such as Figure 4 As shown, this embodiment provides a bidirectional lead-out cylindrical hermetic aluminum electrolytic capacitor, including:

[0052] The circular single lead-out cover plate 14 is composed of the metal cover plate 5, the positive electrode lead-out end 1 and the insulating ring 3 arranged between the positive electrode lead-out end 1 and the metal cover plate 5. The insulating ring 3 is formed by injection molding, and the material of the metal cover plate 5 is It is aluminum alloy, the material of the positive terminal 1 is high-purity aluminum, and the material of the insulating ring 3 is polyester resin.

[0053] Firstly, connect the negative lead-out bar 6 arranged on the capacitor core 9 with the electrolyte solution to the inner bottom of the metal case 8 by laser spot welding, and put the capacitor core 9 with the electrolyte solution into the metal case 8, and then put the The positive lead-out bar 1 arranged on the capacitor core 9 with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com