Method for improving stability of non-noble metal cathode catalyst layer of fuel cell

A cathode catalysis and fuel cell technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of unable to meet the needs of mobile power sources, unstable cathodes, etc., and achieve the effect of improving stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

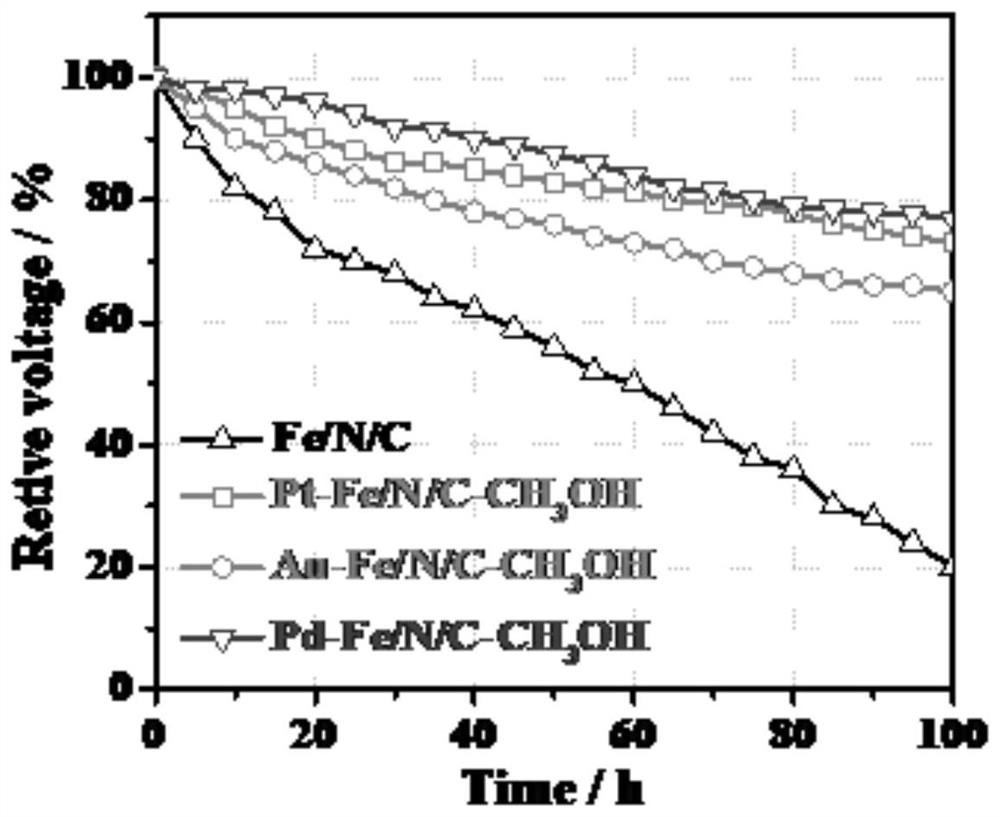

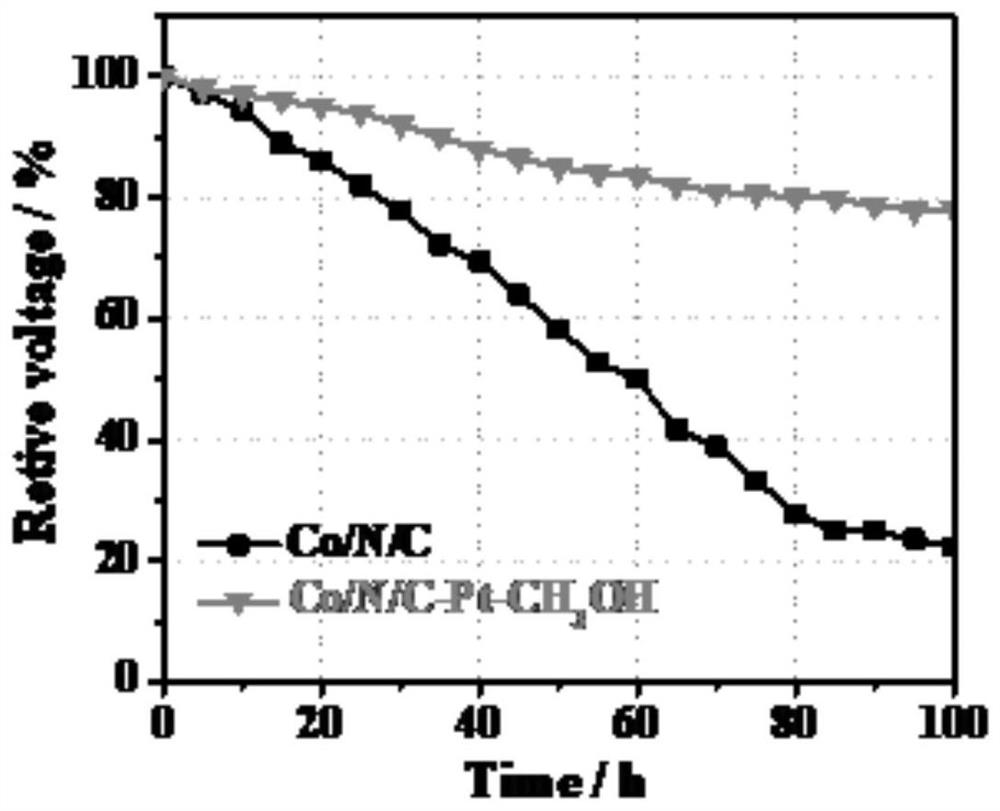

Embodiment 1

[0022] (1) Take 10 mg of Pt@Fe / N / C catalyst compounded in advance and 0.5 mL of 5% Nafion solution to prepare cathode ink. The solvent is water and isopropanol (volume ratio 1:4). After ultrasonic dispersion, use electrostatic The cathode gas diffusion electrode was prepared by spraying, and the cathode catalyst loading was 4 mg cm -2 ;

[0023] (2) The anode catalyst is a commercial PtRu / C catalyst, and the anode gas diffusion electrode is prepared by the same spraying method, and the anode catalyst loading is 4 mg cm -2 ;

[0024] (3), select Nafion 211 membrane as proton exchange membrane, carry out hot pressing to prepare film-forming electrode with proton exchange membrane and the cathode gas diffusion electrode of step (1) and the anode gas diffusion electrode of step (2);

[0025] (4) Assembling the membrane electrode prepared in step (3) into a battery for single-cell testing. The test conditions are: Scribner test system; oxidant: 100% humidified oxygen or air; ano...

Embodiment 2

[0027] (1) Take 10mg of Au@Fe / N / C catalyst compounded in advance and 0.5mL 5% Nafion solution to prepare cathode ink. The solvent is water and isopropanol (volume ratio 1:4). After ultrasonic dispersion, use electrostatic The cathode gas diffusion electrode was prepared by spraying, and the cathode catalyst loading was 4 mg cm -2 ;

[0028] (2) The anode catalyst is a commercial PtRu / C catalyst, and the anode gas diffusion electrode is prepared by the same spraying method, and the anode catalyst loading is 4 mg cm -2 ;

[0029] (3), select Nafion 211 membrane as proton exchange membrane, carry out hot pressing to prepare film-forming electrode with proton exchange membrane and the cathode gas diffusion electrode of step (1) and the anode gas diffusion electrode of step (2);

[0030] (4) Assembling the membrane electrode prepared in step (3) into a battery for single-cell testing. The test conditions are: Scribner test system; oxidant: 100% humidified oxygen or air; anode fu...

Embodiment 3

[0032] (1) Take 10mg of Pd@Fe / N / C catalyst compounded in advance and 0.5mL 5% Nafion solution to prepare cathode ink. The solvent is water and isopropanol (volume ratio 1:4). After ultrasonic dispersion, use electrostatic The cathode gas diffusion electrode was prepared by spraying, and the cathode catalyst loading was 4 mg cm -2 ;

[0033] (2) The anode catalyst is a commercial PtRu / C catalyst, and the anode gas diffusion electrode is prepared by the same spraying method, and the anode catalyst loading is 4 mg cm -2 ;

[0034] (3), select Nafion 211 membrane as proton exchange membrane, carry out hot pressing to prepare film-forming electrode with proton exchange membrane and the cathode gas diffusion electrode of step (1) and the anode gas diffusion electrode of step (2);

[0035] (4) Assembling the membrane electrode prepared in step (3) into a battery for single-cell testing. The test conditions are: Scribner test system; oxidant: 100% humidified oxygen or air; anode fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com