Reverse type recycling method for lithium carbonate battery

A lithium battery and lithium carbonate technology, which is applied in the field of reverse recycling and regeneration of lithium carbonate batteries, can solve the problems of waste battery sorting, recycling and reuse efficiency and low utilization rate, and achieve convenient recycling, efficiency and utilization rate. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

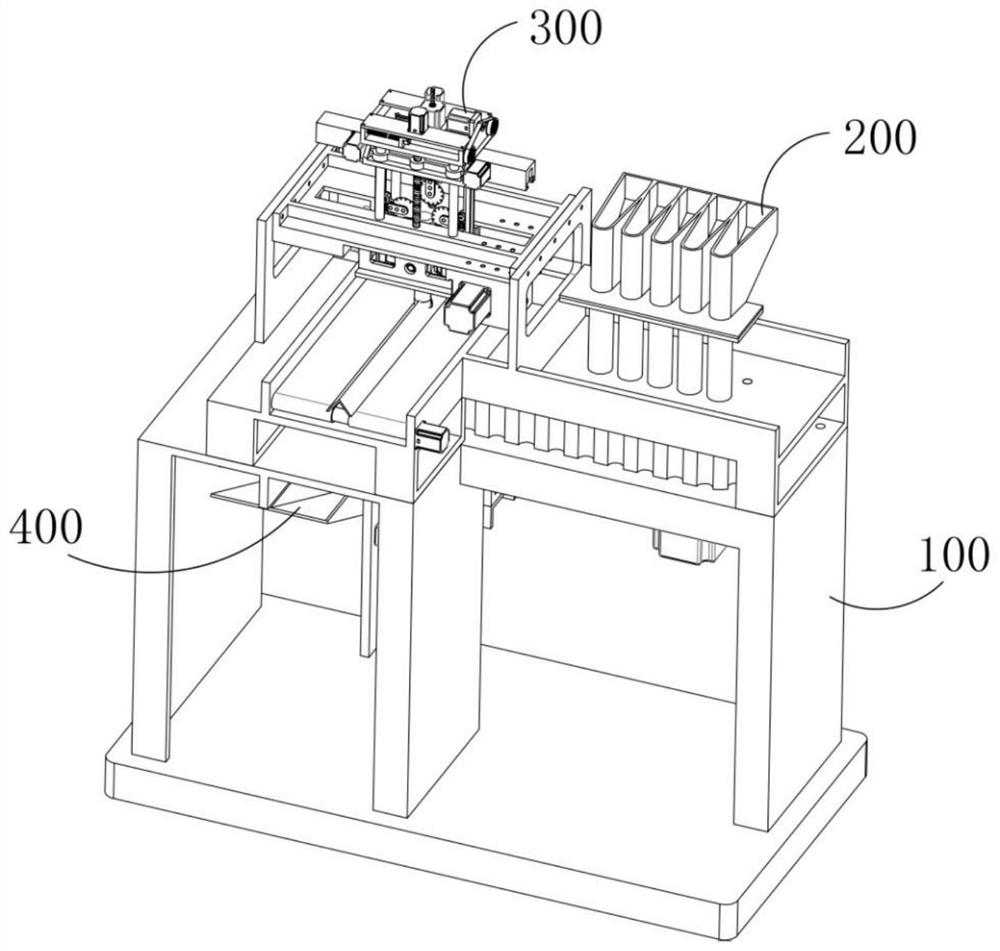

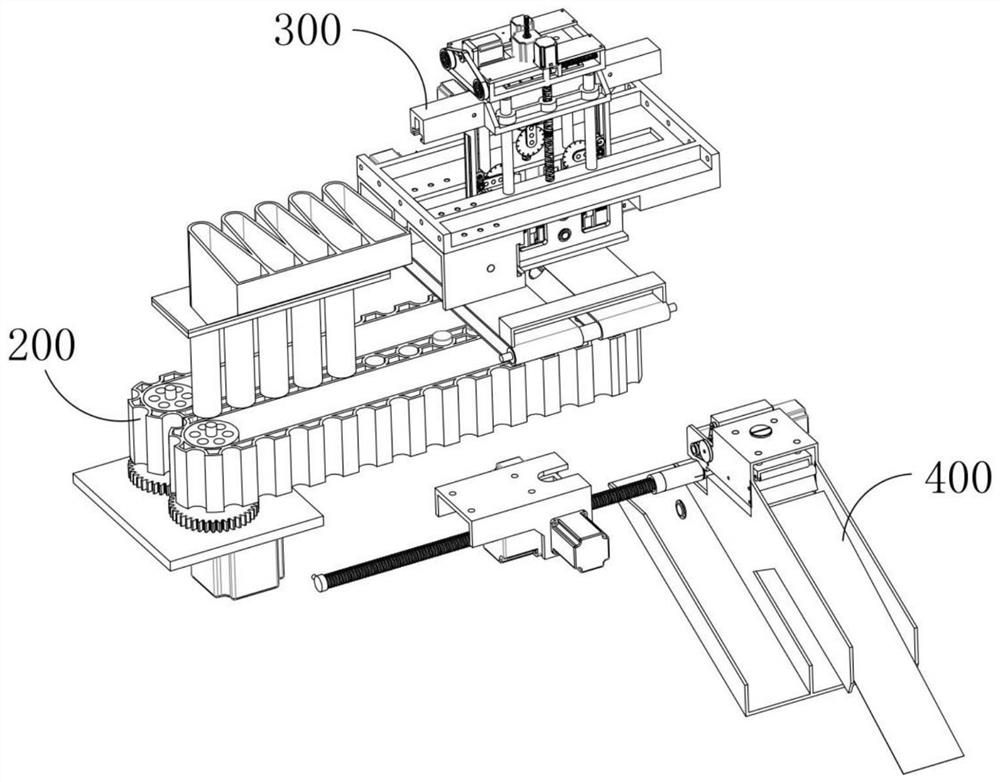

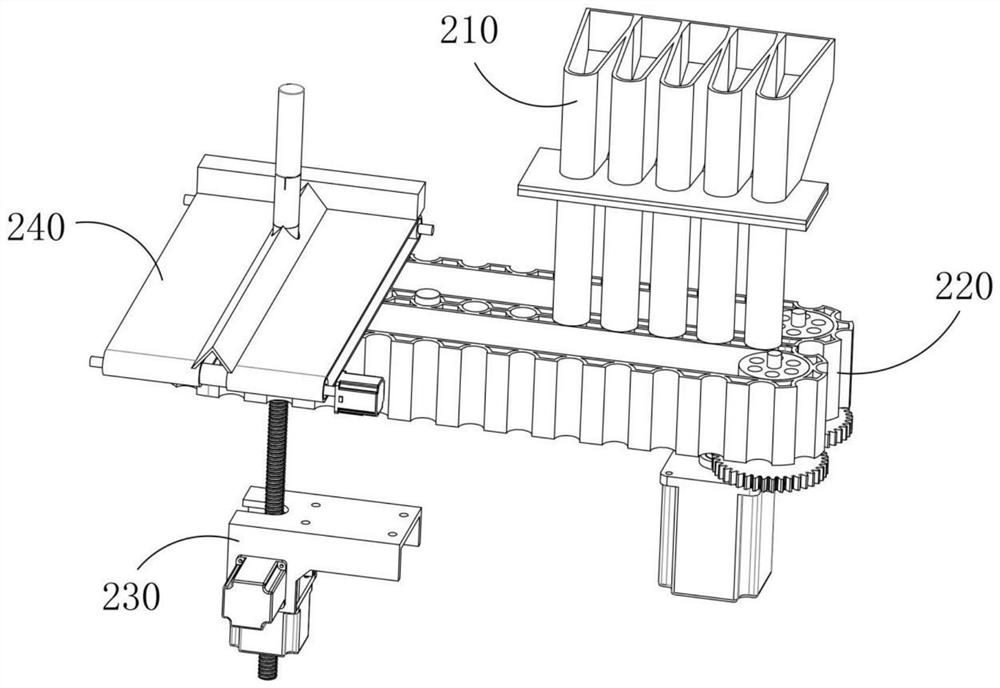

[0040] In order to further illustrate the technical means and function taken in the present invention, the present invention is intended, and the specific embodiments, structures, features and their effects in accordance with the present invention will be described below in conjunction with the drawings and preferred embodiments.

[0041] Such as Figure 22 As shown, the lithium battery typically includes a battery case, a cell, a negative electrode end of the closed end of the battery case, is embedded in the positive end of the battery case opening end, and the positive extreme end is pasted and the battery cell, the battery core includes a diaphragm, an electrolyte, and the like. The diaphragm is typically a layer of helix.

[0042] A retrograde recovery method for lithium carbonate batteries, its steps are:

[0043] S1: The lithium battery is inserted into the guide mechanism 210 in a positive electrode, and the guiding mechanism 210 directs the lithium battery to fall into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com