Sodium hyaluronate essence and preparation method thereof

A technology of sodium hyaluronate and hyaluronic acid, applied in the field of skin care products, can solve the problems of poor absorption of hyaluronic acid essence and general moisturizing effect, so as to enhance anti-enzyme ability, enhance skin moisturizing, and enhance cell activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

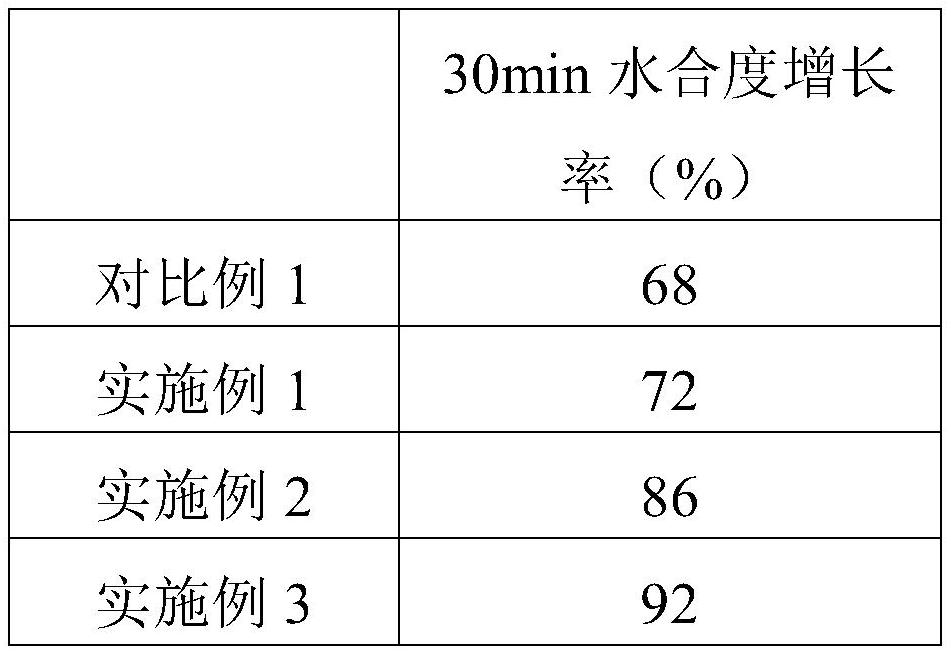

Examples

Embodiment 1

[0064] A preparation method of sodium hyaluronate essence, comprising the steps of:

[0065] S1: Mix 6g of modified sodium hyaluronate, 0.5g of squalane, 0.8g of propolis, 45g of humectant, and 60g of deionized water, then raise the temperature to 80°C and keep it warm for 2 hours to obtain a mixed solution 1; the modified Sodium hyaluronate is butylated sodium hyaluronate; the moisturizing agent is a mixture of glycerin and Luba oil with a mass ratio of 2:1;

[0066] S2: Add 9g of skin conditioner and 4g of Chinese medicine essence extract to the mixed solution 1 prepared in step S1, stir evenly, and lower the temperature of the system to 30°C to obtain mixed solution 2; the mass ratio of the skin conditioner is 2:1 A blend of hydrogenated soy lecithin and cetyl alcohol.

[0067] S3: Add 0.5 g of an absorption enhancer to the mixed solution 2, and stir evenly to obtain a sodium hyaluronate essence; the absorption enhancer is a mixture of menthol and N-methylpyrrolidone with ...

Embodiment 2

[0077] A preparation method of sodium hyaluronate essence, comprising the steps of:

[0078] S1: Mix 6g of modified sodium hyaluronate, 0.5g of squalane, 0.8g of propolis, 45g of humectant, and 60g of deionized water, then raise the temperature to 80°C and keep it warm for 2 hours to obtain a mixed solution 1; the modified Sodium hyaluronate is trifluoroacetylated sodium hyaluronate; the moisturizing agent is a mixture of glycerin and Luba oil with a mass ratio of 2:1;

[0079] S2: Add 9g of skin conditioner and 4g of Chinese medicine essence extract to the mixed solution 1 prepared in step S1, stir evenly, and lower the temperature of the system to 30°C to obtain mixed solution 2; the mass ratio of the skin conditioner is 2:1 A blend of hydrogenated soy lecithin and cetyl alcohol.

[0080] S3: Add 0.5 g of an absorption enhancer to the mixed solution 2, and stir evenly to obtain a sodium hyaluronate essence; the absorption enhancer is a mixture of menthol and N-methylpyrroli...

Embodiment 3

[0090] A preparation method of sodium hyaluronate essence, comprising the steps of:

[0091] S1: Mix 6g of modified sodium hyaluronate, 0.5g of squalane, 0.8g of propolis, 45g of humectant, and 60g of deionized water, then raise the temperature to 80°C and keep it warm for 2 hours to obtain a mixed solution 1; the modified Sodium hyaluronate is a mixture of butyrylated sodium hyaluronate and trifluoroacetylated sodium hyaluronate with a mass ratio of 1:2; the moisturizing agent is a mixture of glycerin and Luba oil with a mass ratio of 2:1 ;

[0092] S2: Add 9g of skin conditioner and 4g of Chinese medicine essence extract to the mixed solution 1 prepared in step S1, stir evenly, and lower the temperature of the system to 30°C to obtain mixed solution 2; the mass ratio of the skin conditioner is 2:1 A blend of hydrogenated soy lecithin and cetyl alcohol.

[0093] S3: Add 0.5 g of an absorption enhancer to the mixed solution 2, and stir evenly to obtain a sodium hyaluronate e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com