A kind of composite sodium hyaluronate gel resisting hyaluronidase hydrolysis and preparation method thereof

A technology of hyaluronidase and sodium hyaluronate, used in pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problems of reduced biocompatibility, easy to cause immune response, etc., so as to delay the degradation time and strengthen the anti-enzyme The ability to decompose and improve the effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

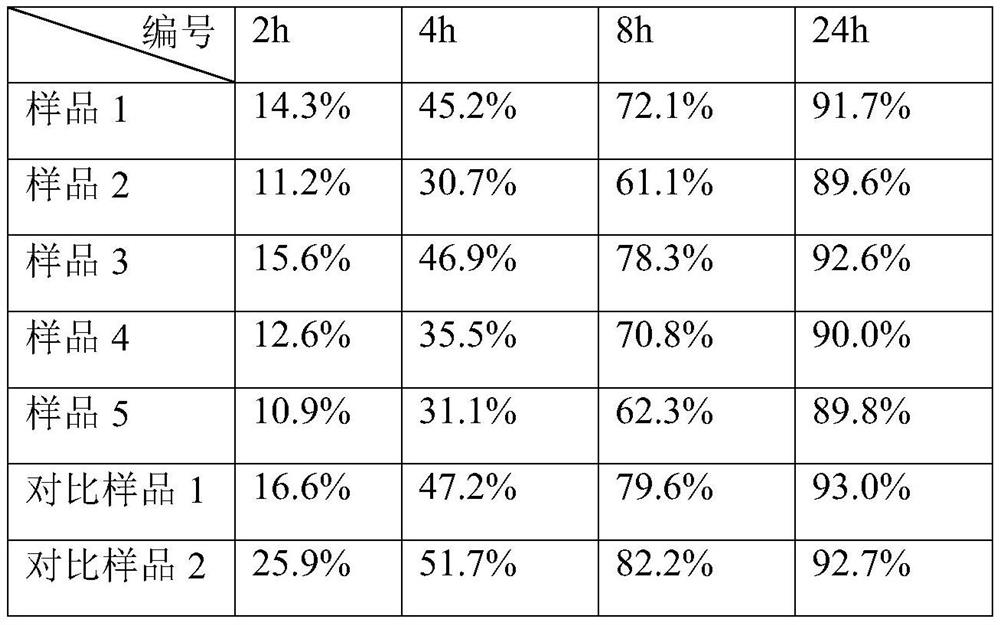

Embodiment 1

[0029] A chondroitin sulfate-sodium hyaluronate composite gel resistant to hydrolysis by hyaluronidase is specifically prepared by the following method:

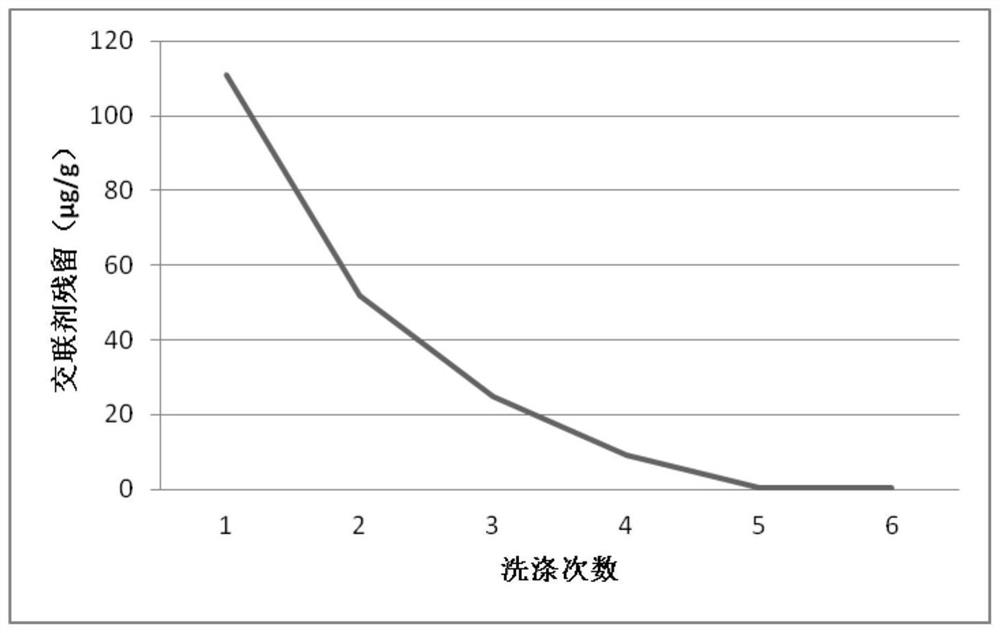

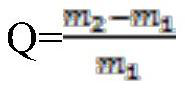

[0030] Weigh 1g of chondroitin sulfate (molecular weight is 10kDa), dissolve it in 50mL NaOH solution (pH=11) and keep stirring, add 5g sodium hyaluronate dry powder (molecular weight is 800kDa), add 1mL BDDE and stir well. The reaction was carried out in an environment with a temperature of 37° C. for 4 h, and the initial cross-linked gel was obtained after the reaction. The gel was precipitated with 95% ethanol, and the precipitate was repeatedly washed with purified water and dried to obtain gel powder.

[0031] Weigh 10g of dry sodium hyaluronate powder (molecular weight 1500kDa) and dissolve it in 50mL of NaOH solution (pH=11), then add 2g of dry powder of primary cross-linked gel and stir evenly, and stir and react at 37°C for 5h. After the reaction, 1 mL of BDDE was added and stirred evenly, and the cross-linking was...

Embodiment 2

[0034] A chondroitin sulfate-sodium hyaluronate composite gel resistant to hydrolysis by hyaluronidase is specifically prepared by the following method:

[0035] Weigh 2g chondroitin sulfate (molecular weight is 10kDa), dissolve it in 50mL NaOH solution (pH=11) and keep stirring, add 5g sodium hyaluronate dry powder (molecular weight is 800kDa), add 1mL BDDE and stir well. The reaction was carried out in an environment with a temperature of 37° C. for 4 h, and the initial cross-linked gel was obtained after the reaction. The gel was precipitated with 95% ethanol, and the precipitate was repeatedly washed with purified water and dried to obtain gel powder.

[0036] Weigh 10g of dry sodium hyaluronate powder (molecular weight 1500kDa) and dissolve it in 50mL of NaOH solution (pH=11), then add 2g of dry powder of primary cross-linked gel and stir evenly, and stir and react at 37°C for 5h. After the reaction, 1 mL of BDDE was added and stirred evenly, and the cross-linking was stre...

Embodiment 3

[0038] A chondroitin sulfate-sodium hyaluronate composite gel resistant to hydrolysis by hyaluronidase is specifically prepared by the following method:

[0039] Weigh 2g chondroitin sulfate (molecular weight is 10kDa), dissolve it in 50mL NaOH solution (pH=11) and keep stirring, add 5g sodium hyaluronate dry powder (molecular weight is 800kDa), add 1mL BDDE and stir well. The reaction was carried out in an environment with a temperature of 37° C. for 4 h, and the initial cross-linked gel was obtained after the reaction. The gel was precipitated with 95% ethanol, and the precipitate was repeatedly washed with purified water and dried to obtain gel powder.

[0040] Weigh 10g of dry sodium hyaluronate powder (molecular weight 1500kDa) and dissolve it in 50mL of NaOH solution (pH=11), then add 2g of dry powder of primary cross-linked gel and stir evenly, and stir and react at 37°C for 5h. After the reaction, 1 mL of BDDE was added to stir evenly, and the cross-linking was streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com