Manufacturing process of anti-injury reinforced anesthesia catheter

An anesthesia catheter and manufacturing process technology, applied in the field of medical devices, can solve problems such as contact, achieve the effect of firm combination, strong anti-bending ability, and increase the success rate of catheterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

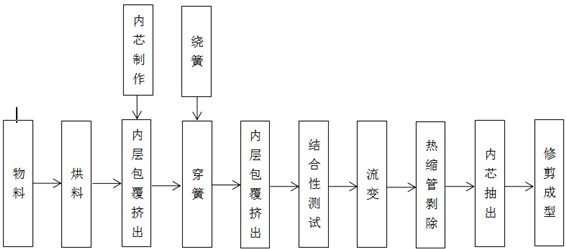

[0031] (1) Baking material: drying polymer plastics at a drying temperature of 100°C and a drying time of 4 hours;

[0032] (2) Inner core production: choose high temperature resistant elastic material, extrude it into a solid tube with a diameter of 0.50mm, as the inner core;

[0033] (3) Inner layer coating extrusion: For the inner layer coating material obtained in steps (1) and (2), select a T-shaped machine head, and feed the inner core from the rear of the machine head along the discharge direction of the machine head. The side of the machine head is fed into the molten material through the rotation of the extruder host screw, the inner core and the material are combined in the die, and then the pipe is drawn through vacuum sizing, cooling, transmission, and forming into a disk to obtain the inner layer coating extruded Out of the tube;

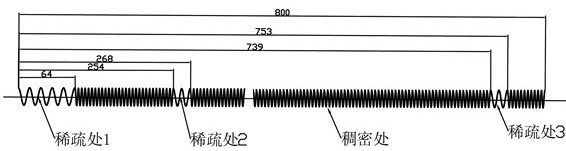

[0034] (4) Winding spring: Select a steel wire with a wire diameter of 0.05-0.10mm, and form the spring through a spring winding mach...

Embodiment 2

[0040] (1) Drying material: drying the material, the drying temperature is 100°C, and the drying time is 4 hours;

[0041] (2) Inner core production: choose high temperature resistant elastic material, extrude it into a solid tube with a diameter of 0.50mm, as the inner core;

[0042](3) Inner layer coating extrusion: For the inner layer coating material obtained in steps (1) and (2), select a T-shaped machine head, and feed the inner core from the rear of the machine head along the discharge direction of the machine head. The side of the machine head is fed into the molten material through the rotation of the extruder host screw, the inner core and the material are combined in the die, and then the pipe is drawn through vacuum sizing, cooling, transmission, and forming into a disk to obtain the inner layer coating extruded Out of the tube;

[0043] (4) Winding spring: Select a steel wire with a wire diameter of 0.05-0.10mm, and form the spring through a spring winding machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com