Combined sand mold

A combination and sand mold technology, which is applied in the direction of casting molding equipment, molds, cores, etc., can solve the problems of mold core shape or fine degree constraints, and achieve the effect of saving overall materials, omitting machine tool processing, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

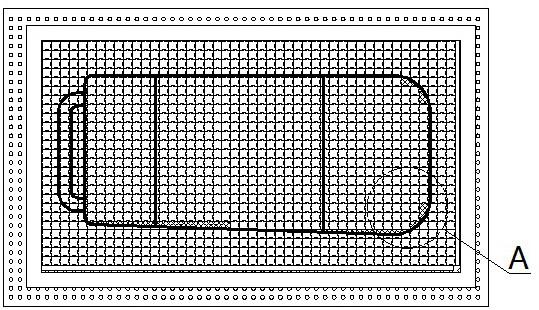

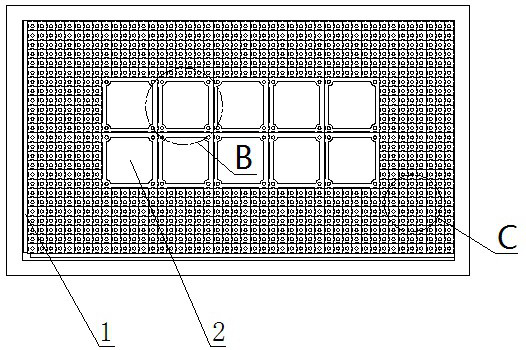

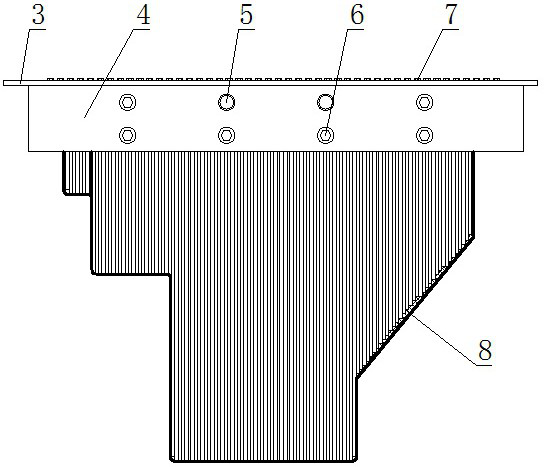

[0032] As shown in the figure, the combined sand mold is suitable for large and medium-sized sand molds, and its preferred embodiment is: a movable interconnection mechanism 14 is arranged around the sand mold column assembly 10 and the sand mold core assembly 2, and the conventional sand mold column assembly 10 between the sand mold core assemblies 2, between the sand mold column assemblies 10 and the sand mold core assemblies 2 can be directly connected flexibly; for the unconventional sand mold column assemblies 4 and sand mold column assemblies 10. Different movable interconnection mechanisms 14 are arranged on both sides of the interconnection adapter plate, and they can be connected flexibly through the interconnection adapter plate. In this way, sand mold column assemblies 4 or sand mold The column assembly 10 is movably connected with the sand mold core assembly 2 .

[0033] The sand mold column assembly 10 is composed of sand mold column units of various lengths and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com