Universal modular chassis structure for new energy automobile

A new energy vehicle, modular technology, applied in the substructure, the layout of the cooling combination of the power unit, the vehicle components, etc., can solve the problems of restricting production capacity, waste of space design, falling off, etc., and achieves good impact resistance and energy absorption. Strong effect and convenient buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

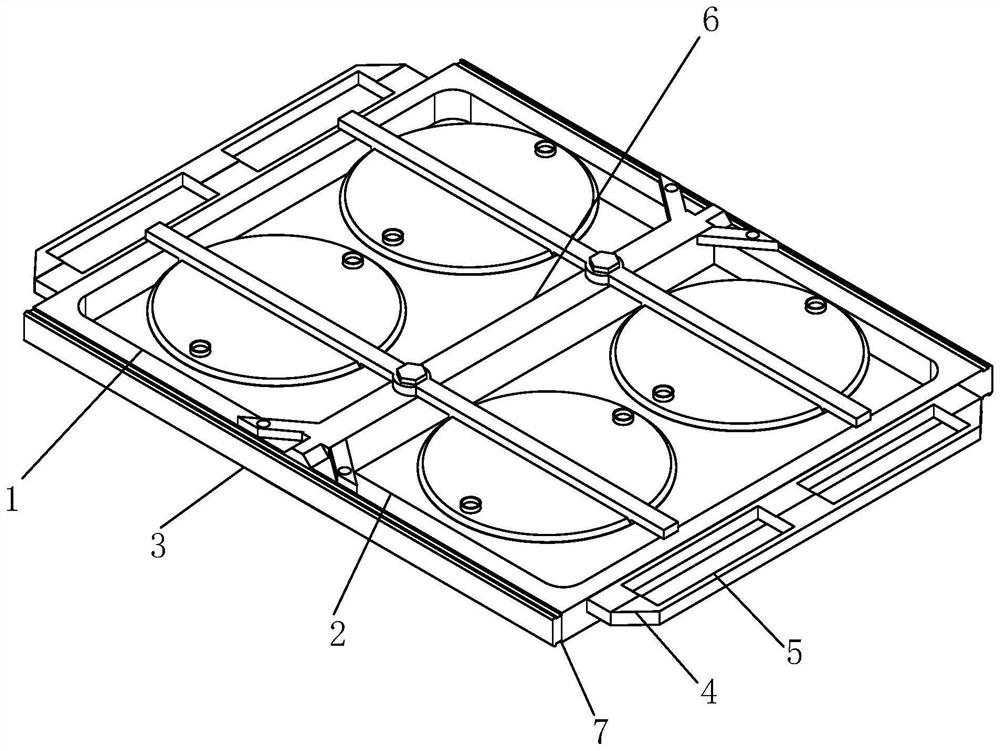

[0028] see figure 1 , the present invention provides a universal modular chassis structure for new energy vehicles through improvement, including a left chassis 1, the right side of the left chassis 1 is connected to the right chassis 2, and the front and rear ends of the left chassis 1 and the right chassis 2 are arranged There are protective side bars 3, connecting pieces 4 are provided on the outer sides of the left chassis 1 and the right chassis 2, openings 5 are opened at the front and rear ends of the connecting pieces 4, and auxiliary stabilizing devices 6 are provided at the inner connection positions of the left chassis 1 and the right chassis 2, A protective structure 7 is provided at the bottom of the left chassis 1 and the right chassis 2 .

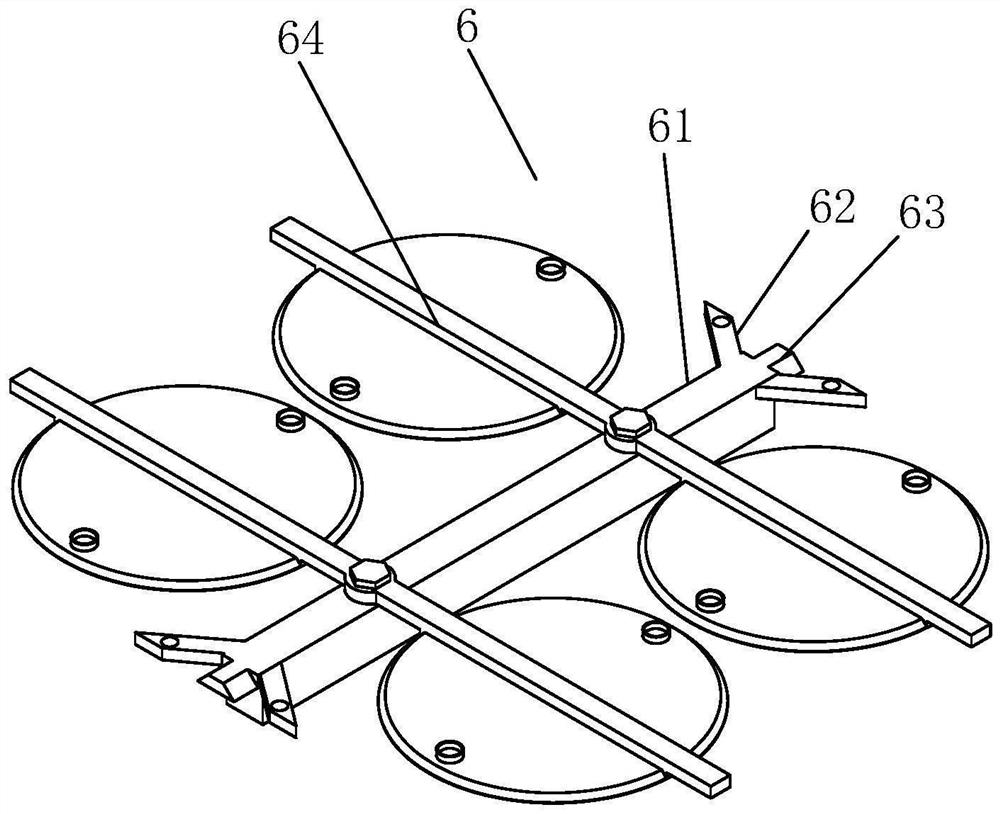

[0029] see figure 2 , the present invention provides a common modular chassis structure for new energy vehicles through improvement. The auxiliary stabilizing device 6 includes a strut 61, a connecting arm 62, a pressing ...

Embodiment 2

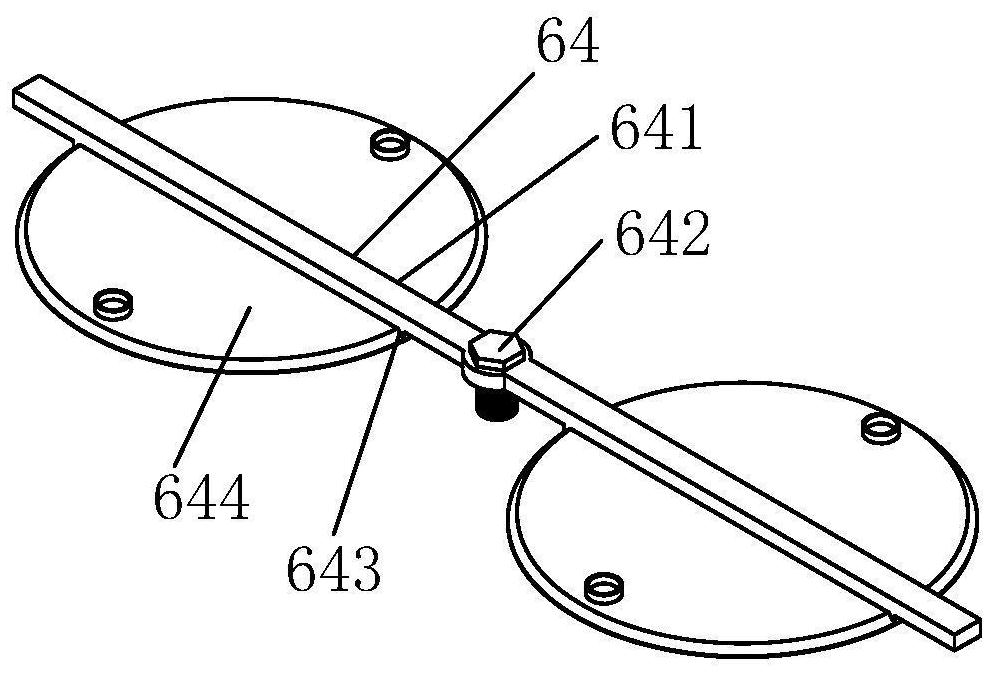

[0034] The present invention provides a general-purpose modular chassis structure for new energy vehicles through improvement. The front and rear ends of the strut 61 are glued to the inner sides of the left chassis 1 and the right chassis 2 by superglue to facilitate disassembly and assembly; The cross bar 641 is sleeved on the outside of the adjusting bolt 642 to facilitate the adjustment of the angle; the inner side of the water inlet pipe 6442 and the water outlet pipe 6443 are provided with sealing rings, and the sealing performance is increased when connecting with the external connecting pipe for water injection.

[0035] The present invention provides a universal modular chassis structure for new energy vehicles through improvement, and its working principle is as follows;

[0036] First, when it is necessary to use the modular chassis structure, first connect the inner sides of the left chassis 1 and the right chassis 2, then install protective side bars 3 at the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com