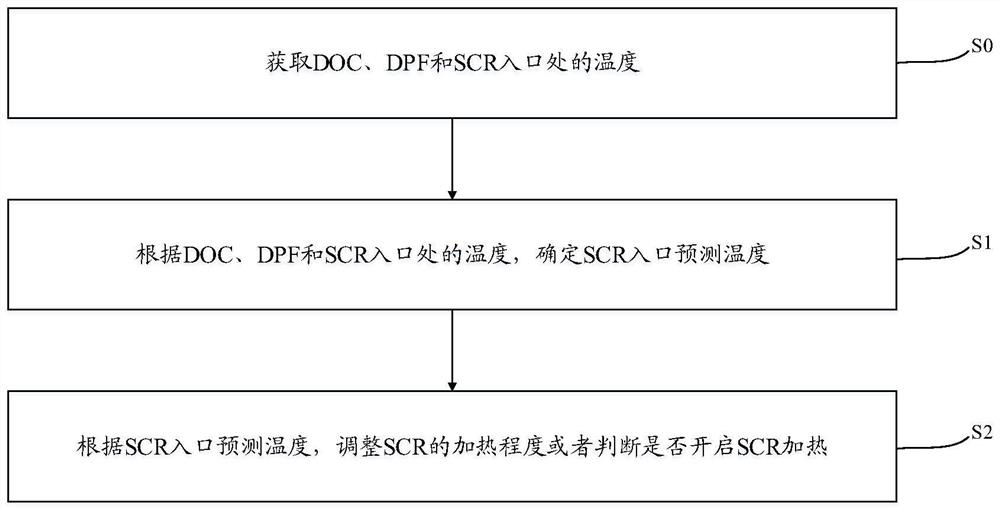

SCR inlet temperature management method and system

A management method and inlet temperature technology, applied in the direction of exhaust gas treatment, electrical control of exhaust gas treatment devices, mechanical equipment, etc., can solve the problems of wasting fuel and affecting the conversion efficiency of SCRNox, and achieve good improvement effect and robustness of results Good, simple and reliable algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

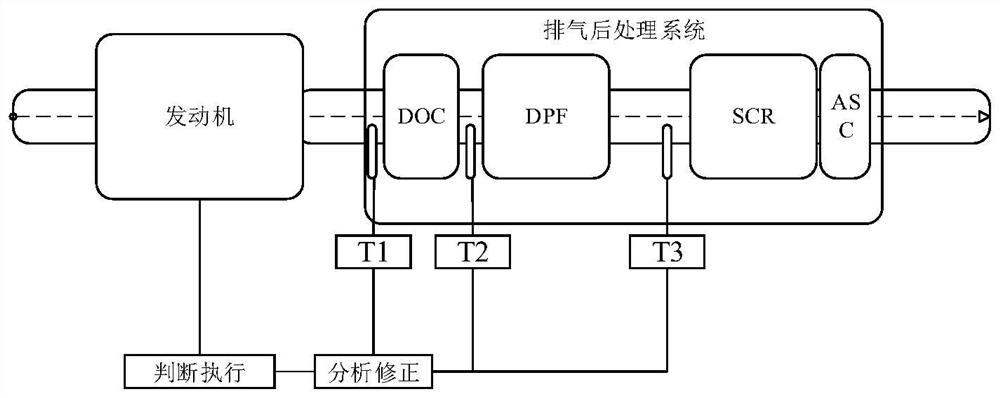

[0057] A1: The first control factor is determined according to the temperature at the entrance of the DOC, and the second control factor is determined according to the temperature at the entrance of the DPF.

[0058] In this example, after the first control factor and the second control factor are calibrated and tabulated through the realization of the test, the temperature T 1 and the temperature T at the inlet of the DPF 2 Obtained by fuzzing.

[0059] A2: According to the first control factor and the second control factor, determine the correction coefficient of the temperature at the inlet of the SCR.

[0060] In this embodiment, according to the formula β=η*α 1 +(1-η)*α 2 , to determine the correction coefficient β of the temperature at the entrance of the SCR; among them, η is a weighting coefficient, which is also calibrated and adjusted according to the test results, and the value range is between 0 and 1. In this example, the value of η is 0.5, and α 1 is the firs...

Embodiment approach A

[0079] Embodiment A: When the predicted temperature at the SCR inlet is greater than or equal to the set temperature, the SCR heating is not turned on. When the predicted temperature at the inlet of the SCR is lower than the set temperature, the SCR heating is turned on.

Embodiment approach B

[0080] Embodiment B: If Embodiment C is adopted in S1, it can be directly judged whether to turn on the SCR heating according to the correction coefficient β. When β is greater than or equal to the set value, SCR heating is not turned on; when β is less than the set value, SCR heating is turned on. The setting value can be calibrated, and the value range is the same as that of β, which is 0~2, and the calibration is 1 in this example. At this time, the correction coefficient β itself can represent the level of the predicted temperature of the SCR inlet, and can be used in S3 to replace the predicted temperature value of the SCR inlet.

[0081] When the SCR heating is turned on, reduce the opening of the engine intake throttle valve or the exhaust gas throttle valve, increase the main fuel injection quantity of the engine, push back the engine timing, turn on the far rear injection, and turn on the second Seven nozzles open fuel injection, adjust VGT opening and / or adjust EGR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com