Catalyst for selective catalytic reduction of ammonia to remove NOx and preparation method thereof

A selectivity and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve catalytic activity reduction, copper and iron loss, hydrothermal stability In order to achieve high NOx conversion efficiency, improve kinetic distribution, high temperature activity and hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the molecular sieve-loaded catalyst used for ammonia selective catalytic reduction to remove NOx comprises the following steps in sequence:

[0030] 1. Pre-calcining: Calcining the ZSM-35 molecular sieve at a temperature of 120°C for 0.5 hours. Through the pre-calcination treatment, the organic matter of the molecular sieve channel and the template agent on the surface is removed, which is more conducive to the subsequent ion exchange.

[0031] 2. Ion exchange: Disperse the pre-calcined ZSM-35 molecular sieve into water at room temperature to form a molecular sieve slurry; at the same time, in another reaction kettle, dissolve copper chloride at room temperature, and then pour it into the molecular sieve slurry. Stirring constantly, stir for 3 hours. Wherein, the weight ratio of copper ion to ZSM-35 molecular sieve is 1%.

[0032] 3. The molecular sieve after cation exchange is washed with deionized water, then dried at 50° C. for 3 hours, an...

Embodiment 2

[0035] This example is basically the same as Example 1, the only difference being that the molecular sieve is Cu-ZSM-5 molecular sieve.

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 1, the only difference being that the molecular sieve is a Beta molecular sieve.

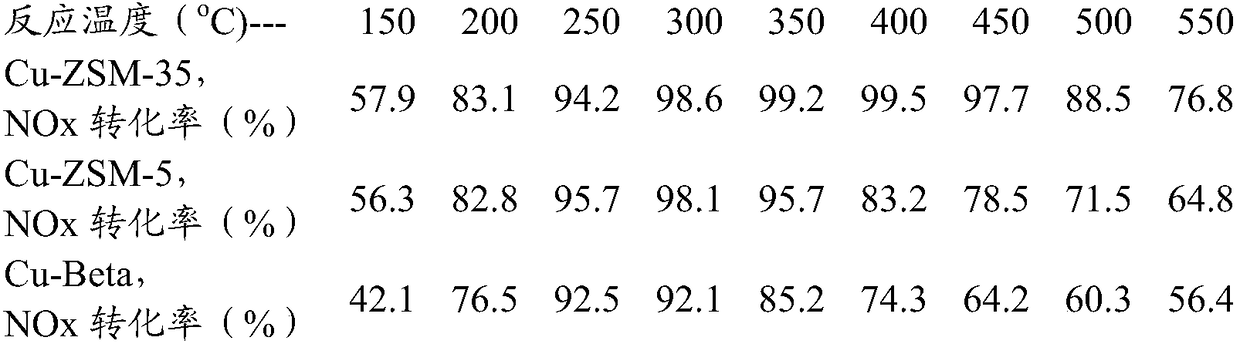

[0038] The performance test results of the molecular sieve supported catalyst prepared in Examples 1-3 are shown in Table 1 below:

[0039] Table 1

[0040]

[0041] The reaction space velocity is 90000(h -1 ), 800ppmNH 3 , 800ppmNO, 8%O 2 ,

[0042] It can be seen from Table 1 that the catalyst prepared in Example 1 can have high NOx conversion efficiency under conditions of wider temperature range and high space velocity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com