Steel-making intelligent centralized control intelligent application platform construction method

An application platform and construction method technology, applied in application software and intelligent manufacturing, iron and steel metallurgy fields, can solve the problems of significant differences in process models, multi-source heterogeneity of data and information, and difficulty in intelligent manufacturing, so as to improve product quality, stability and efficiency. Effectiveness of labor productivity, streamlining operators, resolving data silos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

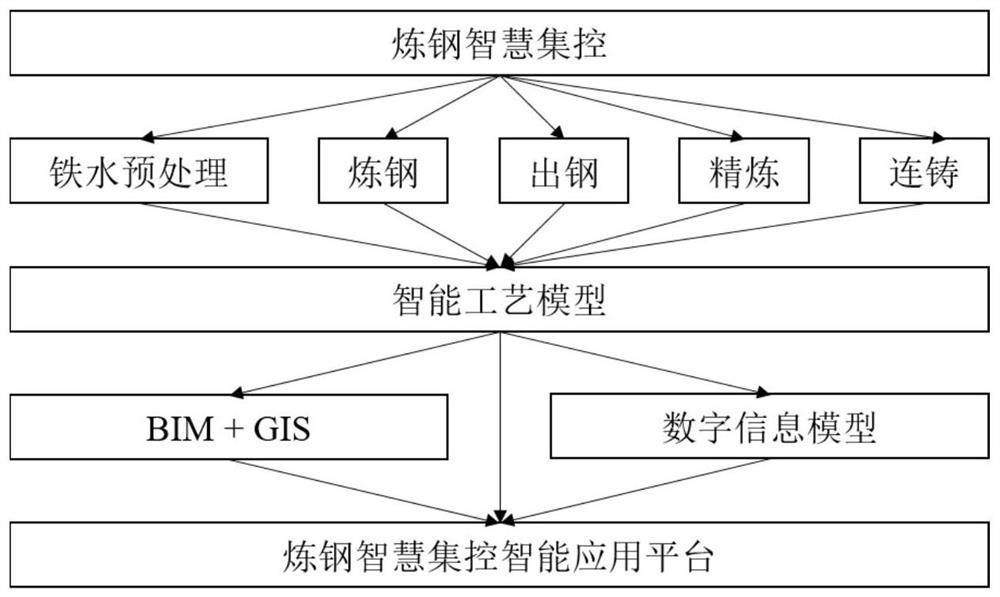

[0024] A method for constructing an intelligent application platform for intelligent centralized control of steelmaking in this embodiment is specifically a method for constructing an intelligent application platform for intelligent centralized control of steelmaking in a B / S structure, including pretreatment of molten iron, BOF steelmaking, BOF tapping, LF Refining and billet continuous casting, the steps are:

[0025] Step 1: According to the converter steelmaking smart centralized control technology plan, the converter steelmaking process is decomposed into hot metal pretreatment, converter steelmaking, converter tapping, LF refining, and billet continuous casting. The main equipment includes two 150t hot metal desulfurization pre Treatment furnace, two 150t converters, two 150t LF refining furnaces, two 7-machine, 7-strand 165mm×165mm billet continuous casting machines, as well as supporting several molten iron tanks, ladles, slag tanks, ladle trolleys, and slag tank trolle...

Embodiment 2

[0031] A method for constructing an intelligent application platform for intelligent centralized control of steelmaking in this embodiment is specifically a method for constructing an intelligent application platform for intelligent centralized control of electric furnace steelmaking with a C / S architecture, including scrap steel supply, electric furnace steelmaking, electric furnace tapping, and LF refining , slab continuous casting, the steps are:

[0032] Step 1: According to the electric furnace steelmaking smart centralized control technology plan, the electric furnace steelmaking process is decomposed into scrap steel supply, electric furnace steelmaking, electric furnace tapping, LF refining, and slab continuous casting. The main equipment includes four scrap storage areas, one 150t electric furnace, two 150t LF refining furnaces, two slab continuous casting machines with a thickness of 150-250mm and a width of 1000-1800mm, as well as a number of supporting ladle tanks, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com