Cable comprehensive processing equipment

A comprehensive processing and cable technology, which is applied to equipment for dismantling/armoring cables, equipment for cutting/splitting cables, installation of cables, etc., can solve problems such as unfavorable construction personnel for construction, and reduce the efficiency of power grid distribution construction, etc., to achieve Improve construction efficiency, protect safety, and facilitate portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

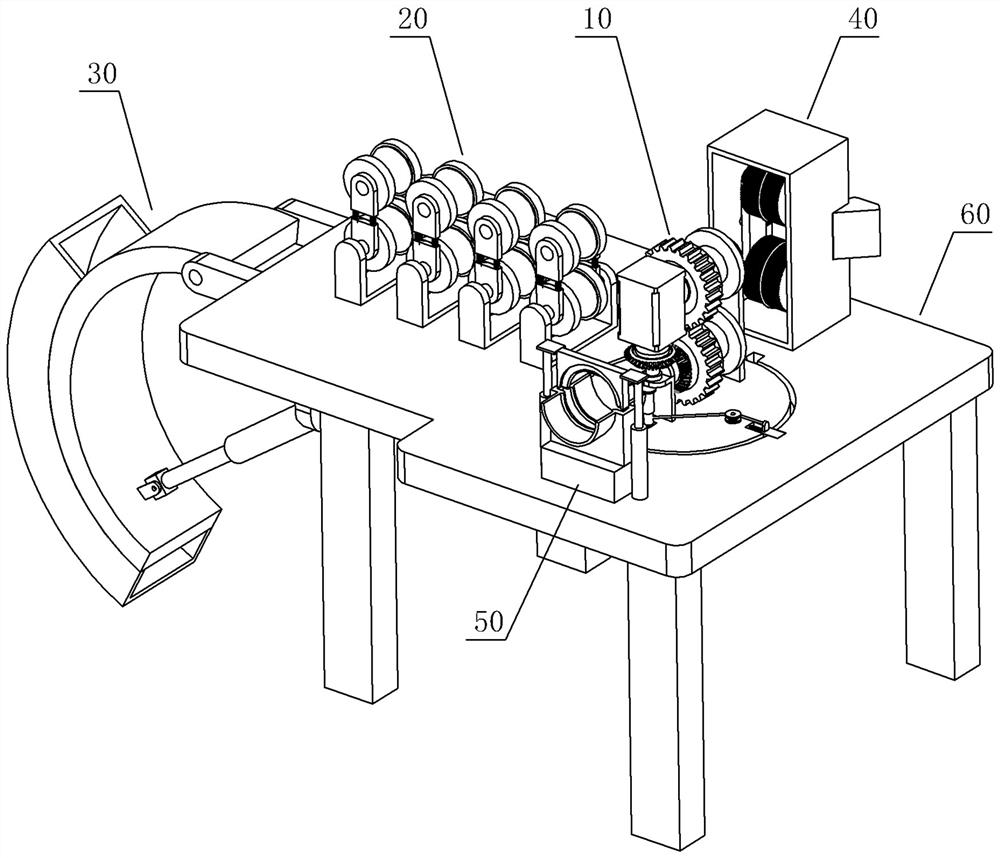

[0030] Embodiment Cable integrated processing equipment

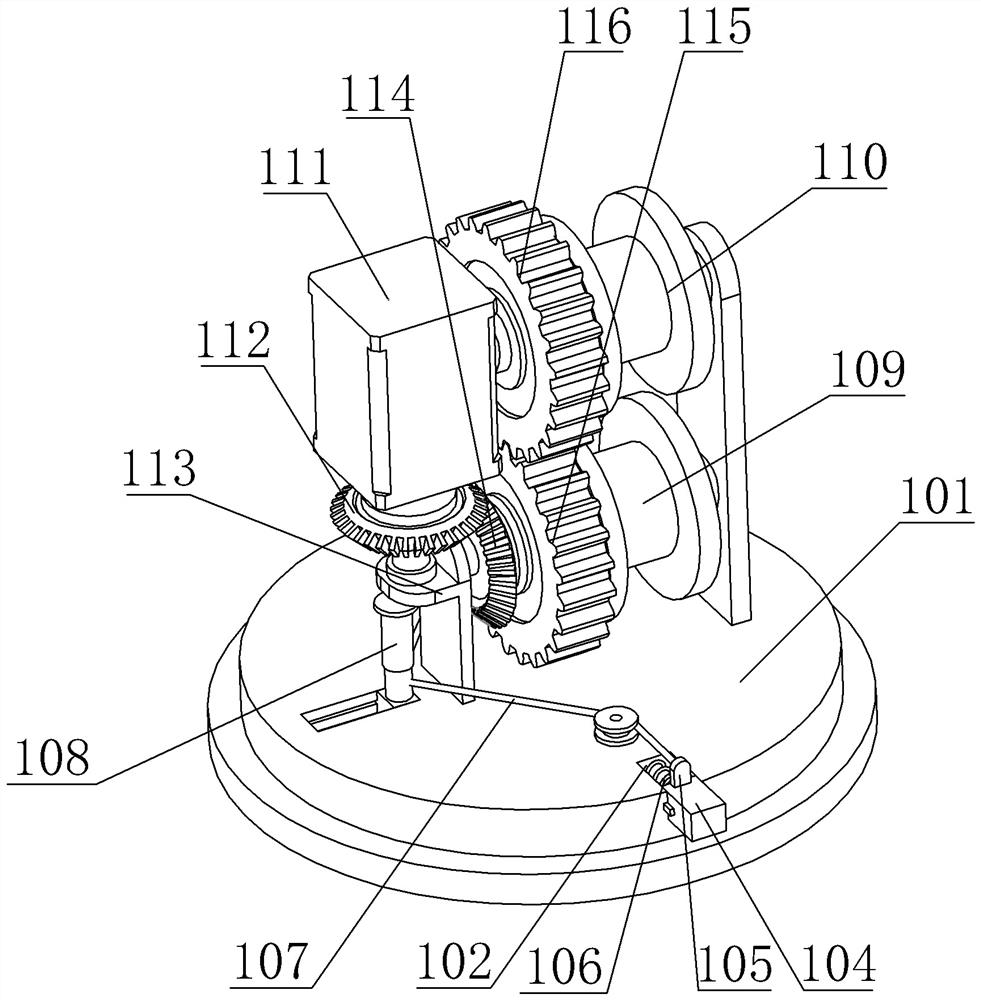

[0031] This example Figure 1 to Figure 7 As shown, it is a kind of comprehensive processing equipment for cables, including an operation table 60, on which a straightening mechanism 20 for straightening cables, a bending mechanism 30 for bending cables, and a bending mechanism 30 for bending cables are arranged on the operation table 60 A stripping mechanism 40 for cable stripping, a cutting mechanism 50 for cutting the cable, and a push mechanism 10 for delivering the cable to the aforementioned mechanisms. The propulsion mechanism 10 is located in the middle of the console 60 , the above-mentioned mechanisms are arranged in the circumferential direction of the propulsion mechanism 10 and the cable delivery direction faces the propulsion mechanism 10 , and the cables are transported to the above-mentioned mechanism by the rotation of the propulsion mechanism 10 .

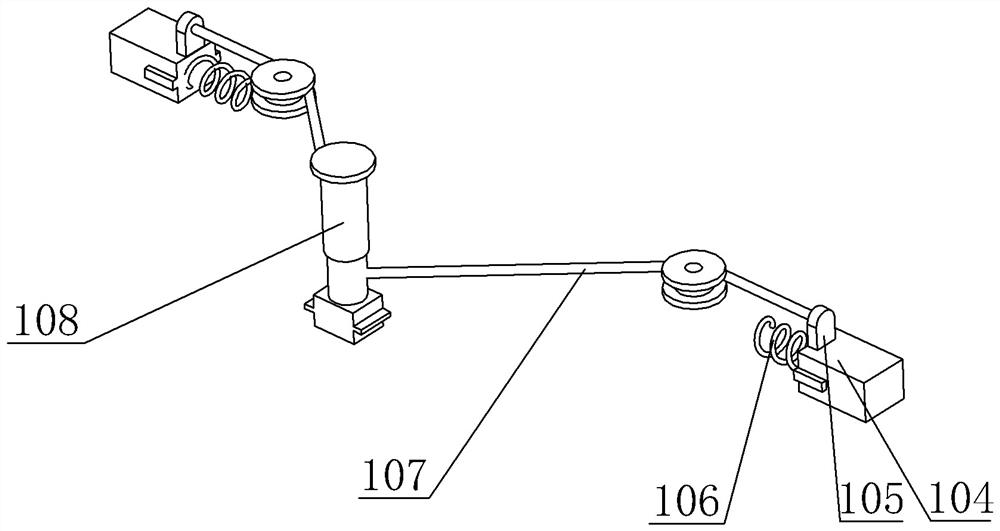

[0032] The propulsion mechanism 10 is rotatably disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com