Processing equipment for fireproof layer of fireproof plate

A processing equipment and fireproof layer technology, which is applied in the field of fireproof layer processing equipment for fireproof boards, can solve problems such as inability to tighten the fireproof layer, increase the labor intensity of staff, and reduce the cutting accuracy of the fireproof layer, so as to reduce labor intensity and improve transmission quality , Improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

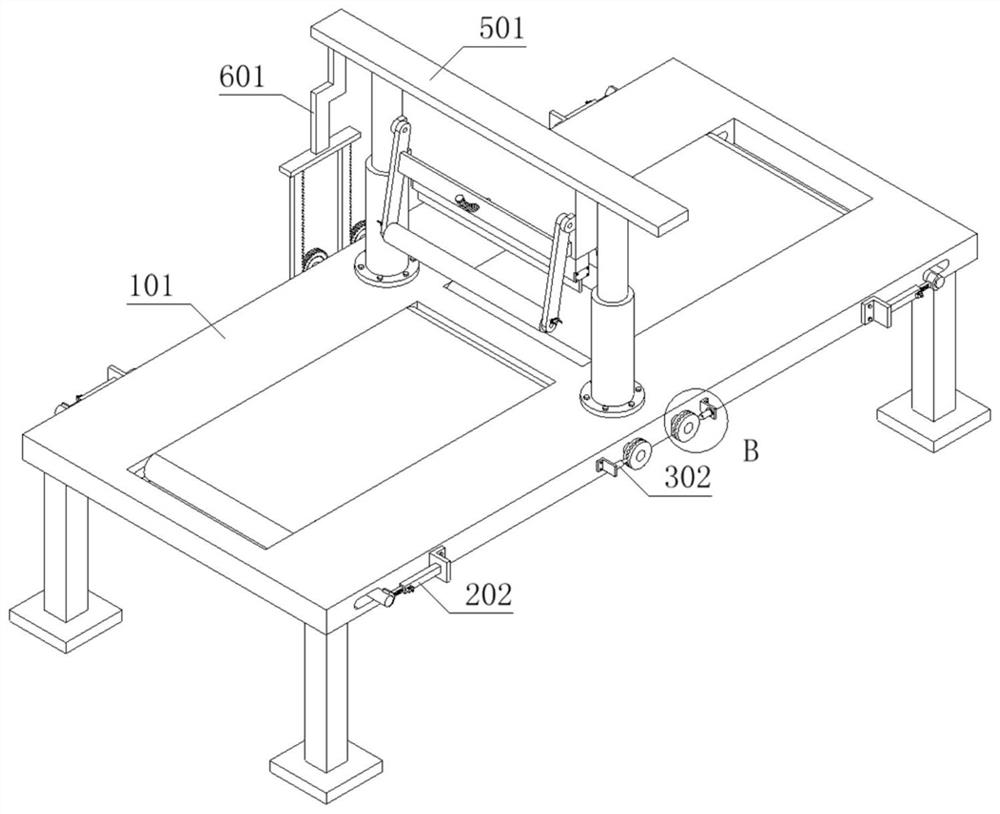

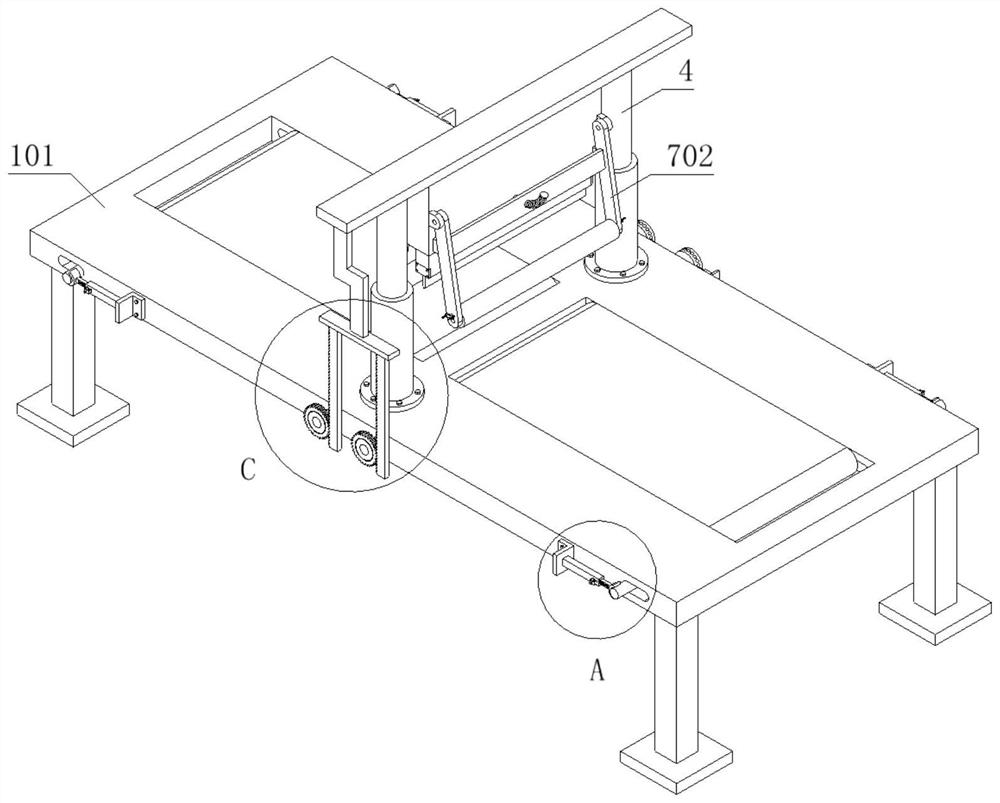

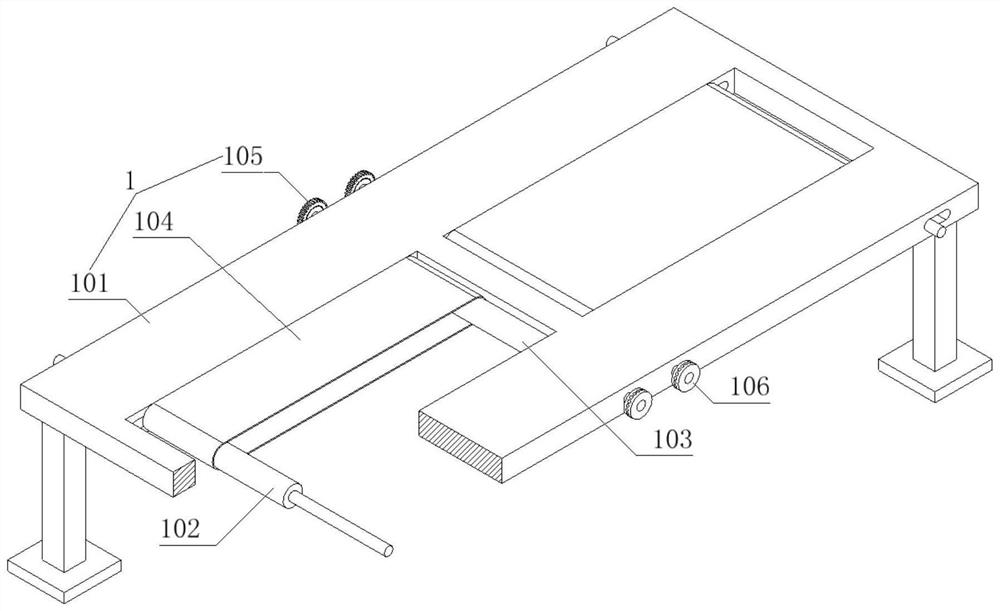

[0071] Example: please refer to Figure 1 to Figure 14 :

[0072] The present invention proposes a fireproof board fireproof layer processing equipment, including a transmission device 1; two sets of limit parts 3 are installed on the front side of the transmission device 1, and two hydraulic cylinders 4 are installed on the top of the transmission device 1, and two A cutting mechanism 5 is installed on the top of the hydraulic cylinder 4, and a driving assembly 6 is installed at the bottom of the cutting mechanism 5; the tensioning assembly 2, the tensioning assembly 2 has a total of four groups, and the four groups of the tensioning assembly 2 are installed in the transmission device 1. The front and rear sides of the cutting mechanism 5 are installed with wrinkle removal assemblies 7 , and the front and rear sides of the two groups of wrinkle removal assemblies 7 are installed with fixing devices 8 .

[0073] Furthermore, according to embodiments of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com