Automobile plastic skylight manufacturing process

A manufacturing process and sunroof technology, applied in the field of automobile plastic sunroof manufacturing process, can solve the problems of increasing fuel consumption, increasing the weight of the whole vehicle, etc., and achieve the effects of reducing emissions, reducing fuel consumption, and reducing the number of tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

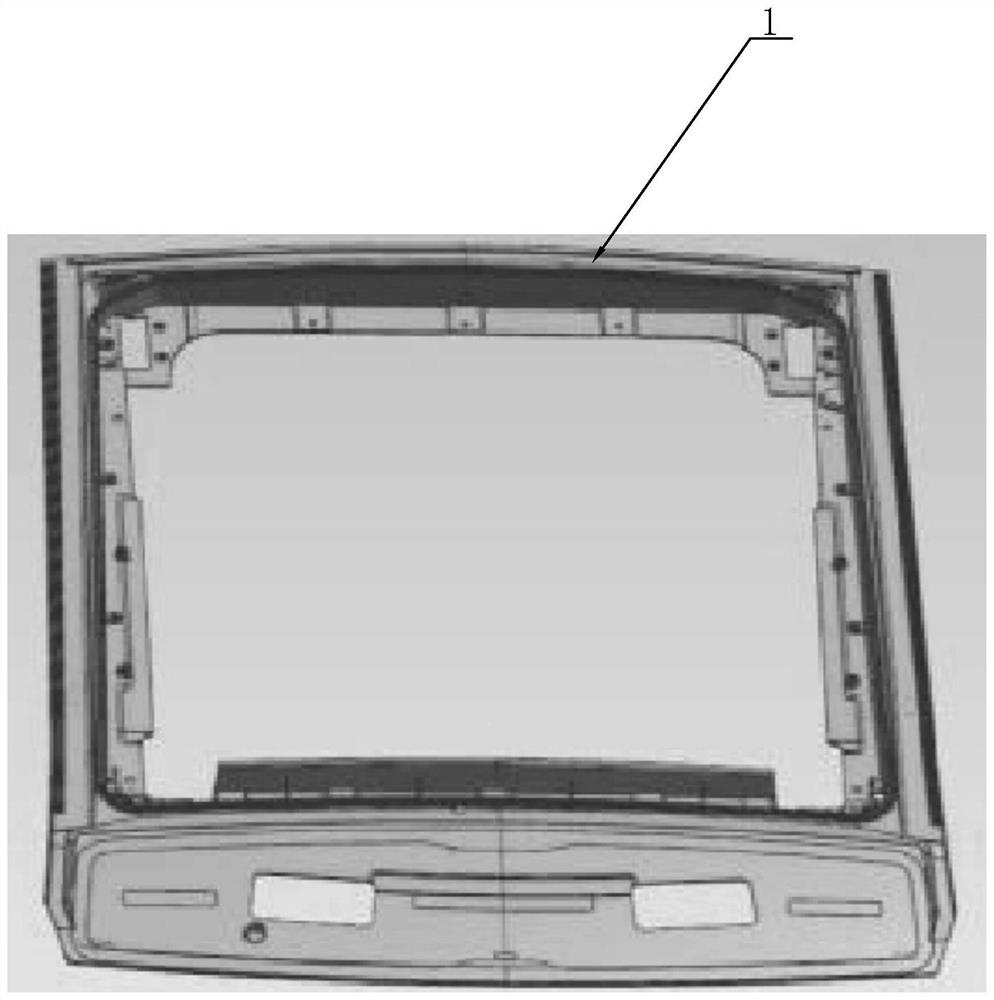

Embodiment 1

[0029] A car plastic skylight manufacturing process, including the following steps:

[0030] S1, raw material examination: Check the raw material number, quantity, appearance, color, etc., and inspect the material inspection report to ensure that the raw materials are correct, qualified, in line with production requirements;

[0031] S2, raw material storage: The raw materials after the test are passed, and the placement is placed according to the warehouse;

[0032] S3, injection molding: At a certain temperature, a fully molten plastic material (carbonate material) is stirred through the screw, and then incorporate the cavity with a high pressure, after cooling, the molded sunroof is obtained. There is mainly in the same mode, the rubber, pressure pressure, cooling, molding, etc. Cost and the simplicity of material recovery;

[0033] S4, trim: After molding, take out the sunroof, repair excess material at the gate, so that the appearance of the sunroce is more beautiful;

[0034...

Embodiment 2

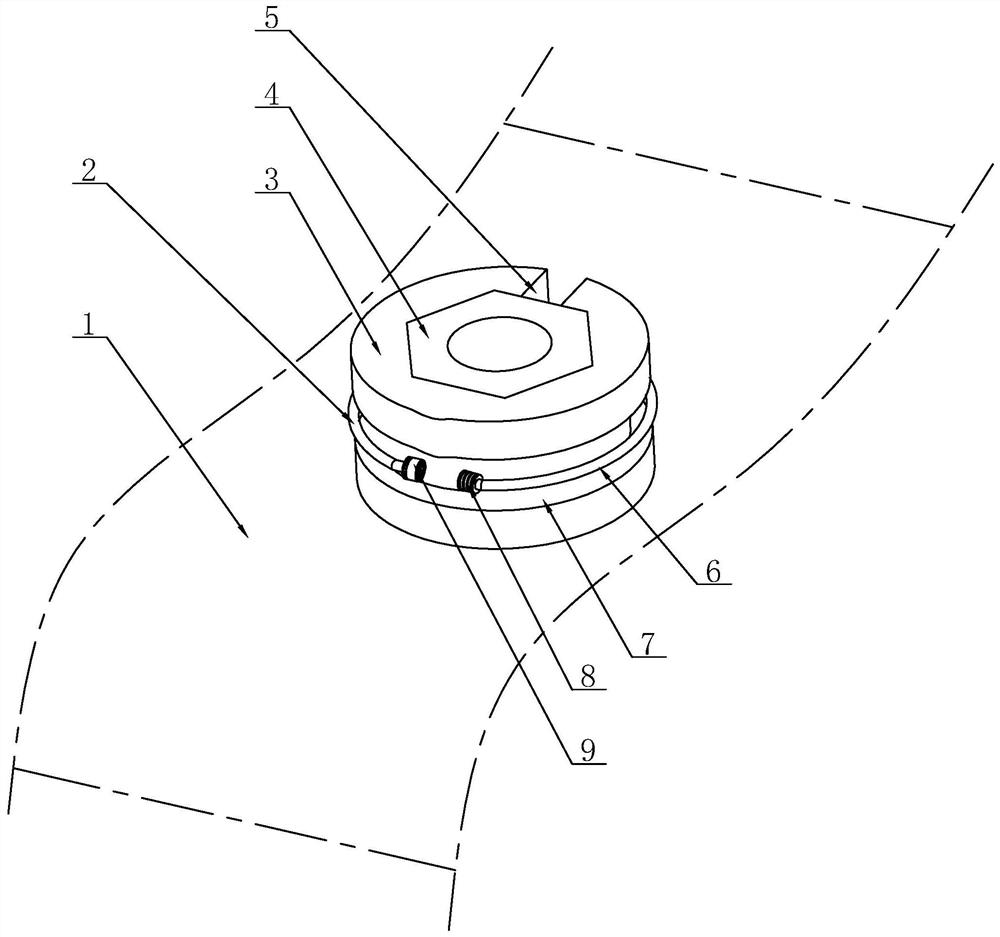

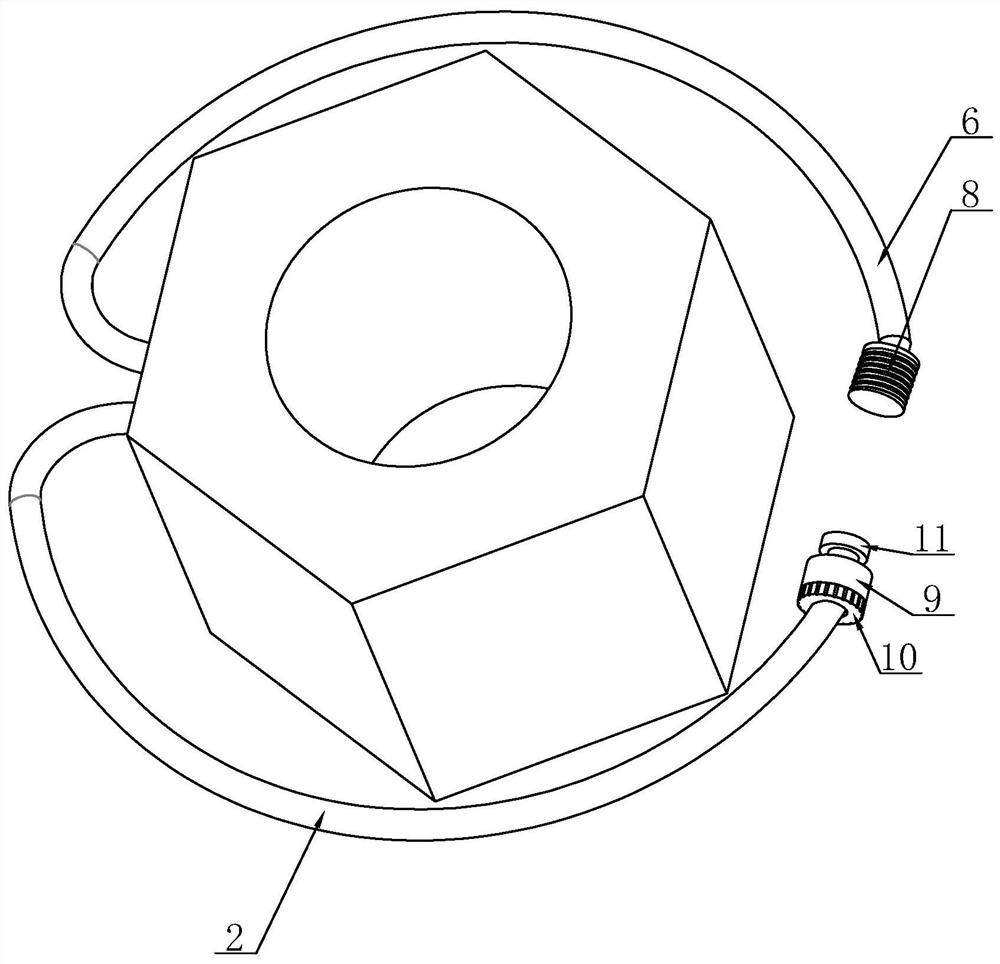

[0046] In the fixing method of the nut in this embodiment, the fixing column 3 is fixed to the sunroof 3, and the fixing column 3 is provided with a mounting groove, the nut 4 is mounted to the mounting slot, and the outer wall of the nut 4 is fixedly coupled. 2 and the second connection line 6, the side perforation 5 is provided on the side wall of the fixed column 3, the first connecting line 2 and the second connection line 6 are all passing through the side perforation 5, and the first connecting line 2 passes through the side perforation 5. One end is fixed, the raised 11 is fixed, and the first connecting wire 2 is provided with a rotating ring 10, and the rotation ring 10 is fixed to the rotary ring 9, and the inner wall of the threaded ring 9 is provided with an internal thread, and the second cable 6 is away from the fixed column 3. At one end, there is a connection post 8, and the outer wall of the connecting post 8 is provided with an external thread, and the external t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com