Wear-resistant master batch as well as preparation method and application thereof

A masterbatch, single-end technology, applied in the field of plastics, to achieve the effect of maintaining light transmission, reducing friction and grinding, and reducing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

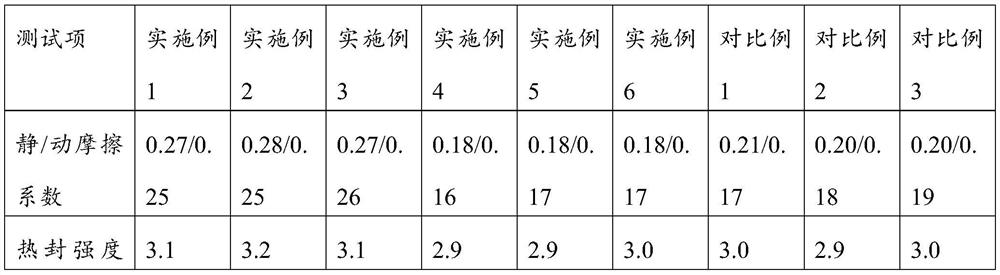

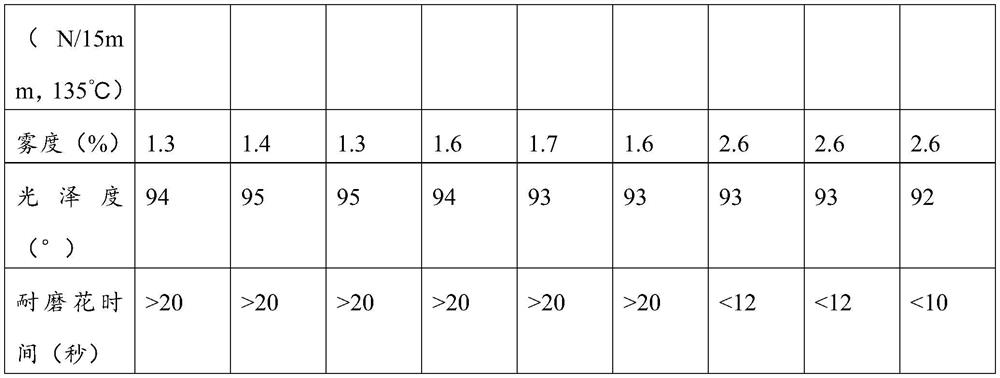

Examples

Embodiment 1

[0048] Example 1: Preparation of Wear-Resistant Masterbatch

[0049] A wear-resistant masterbatch, the melt index of the masterbatch at 2.16kg at 230°C is 12.5g / 10min, the moisture content is 300ppm, and the ash content is 12000ppm.

[0050] The raw material components for preparing the above masterbatch, in parts by weight, include: 92 parts of carrier (propylene-ethylene-butylene copolymer), 2.5 parts of single-terminal carboxylated polypropylene wax, double-terminal hydroxylated polydimethylsiloxane 5 parts of alkanes, 0.5 parts of organic spherical anti-sticking agent (PMMA microspheres).

[0051] The preparation method of the above-mentioned wear-resistant masterbatch comprises the following steps:

[0052] (1) Stir and mix the carrier, single-end carboxyl polypropylene wax, double-end hydroxy polydimethylsiloxane, and organic spherical anti-sticking agent. The stirring speed is 200 rpm, and the stirring time is 8 minutes to prepare the mixture ;

[0053] (2) Put the m...

Embodiment 2

[0054] Example 2: Preparation of Wear-Resistant Masterbatch

[0055] A wear-resistant masterbatch, the melt index of the masterbatch at 2.16kg at 230°C is 12.0g / 10min, the moisture content is 300ppm, and the ash content is 12000ppm.

[0056] The raw material components for preparing the above masterbatch, in parts by weight, include: 92 parts of carrier (propylene-ethylene-butylene copolymer), 2.5 parts of single-terminal carboxylated polypropylene wax, double-terminal hydroxylated polydimethylsiloxane 5 parts of alkanes, 0.5 parts of organic spherical anti-sticking agent (PMMA microspheres).

[0057] The preparation method of the above-mentioned wear-resistant masterbatch comprises the following steps:

[0058] (1) Stir and mix the carrier, single-end carboxyl polypropylene wax, double-end hydroxy polydimethylsiloxane, and organic spherical anti-sticking agent. The stirring speed is 200 rpm, and the stirring time is 8 minutes to prepare the mixture ;

[0059] (2) Put the m...

Embodiment 3

[0060] Embodiment 3: the preparation of wear-resistant masterbatch

[0061] A wear-resistant masterbatch, the melt index of the masterbatch at 2.16kg at 230°C is 13.0g / 10min, the moisture content is 300ppm, and the ash content is 12000ppm.

[0062] The raw material components for preparing the above masterbatch, in parts by weight, include: 92 parts of carrier (propylene-ethylene-butylene copolymer), 2.5 parts of single-terminal carboxylated polypropylene wax, double-terminal hydroxylated polydimethylsiloxane 5 parts of alkanes, 0.5 parts of organic spherical anti-sticking agent (PMMA microspheres).

[0063] The preparation method of the above-mentioned wear-resistant masterbatch comprises the following steps:

[0064] (1) Stir and mix the carrier, single-end carboxyl polypropylene wax, double-end hydroxy polydimethylsiloxane, and organic spherical anti-sticking agent. The stirring speed is 200 rpm, and the stirring time is 8 minutes to prepare the mixture ;

[0065] (2) Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com