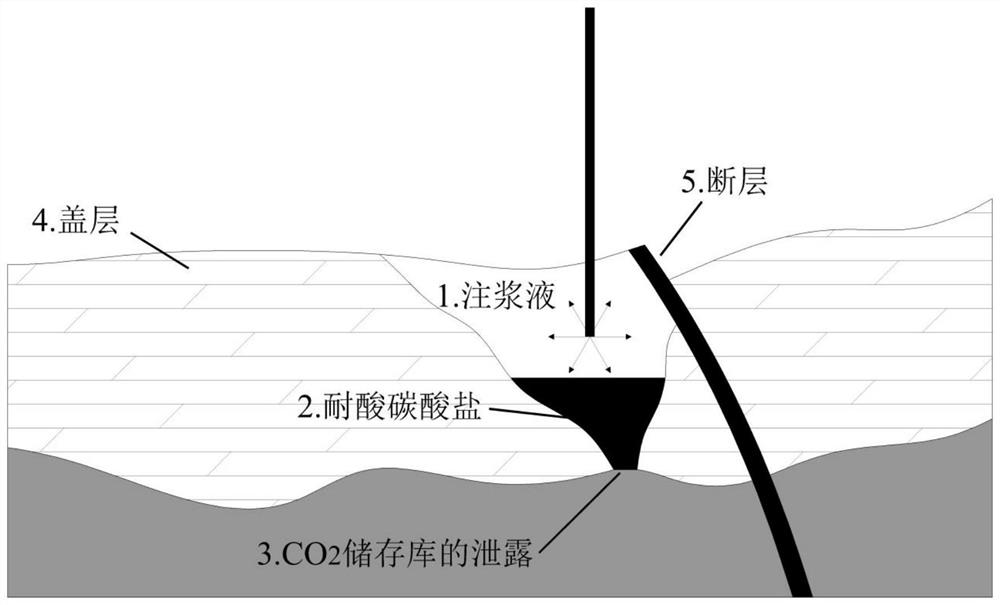

Chemical grouting fluid for repairing CO2 leakage of deep stratum and preparation method of chemical grouting fluid

A technology of CO2 and grouting, which is applied in the direction of chemical instruments and methods, other chemical processes, drilling compositions, etc., can solve the problems of difficult injection into micro-cracks, poor formation repair effect, etc., and is beneficial to carbon sequestration and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

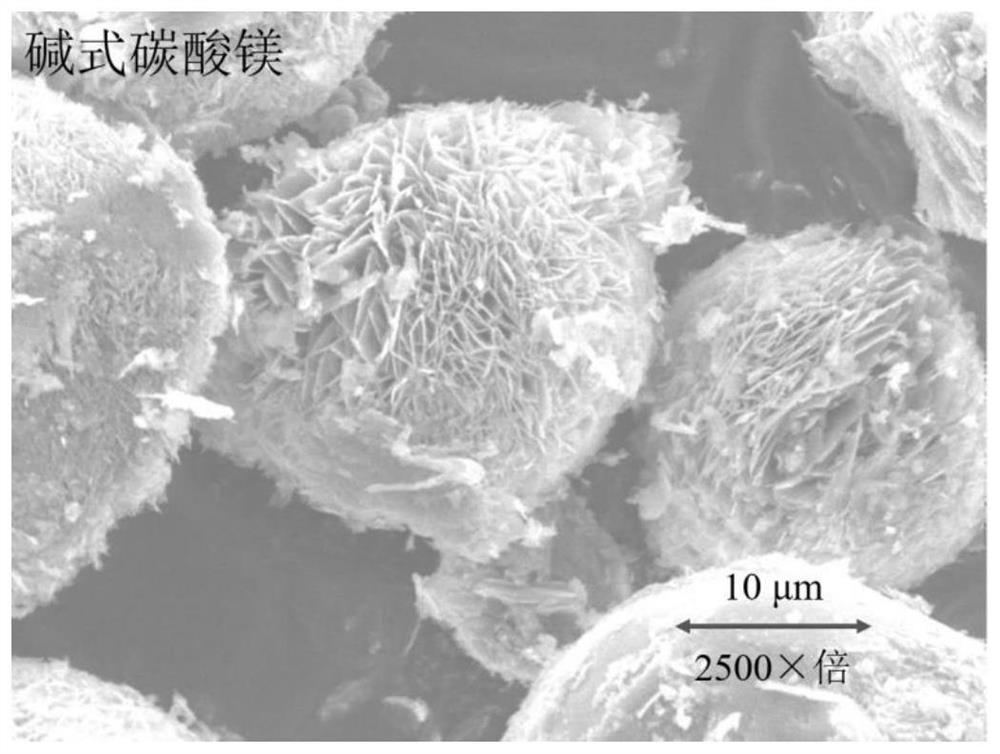

[0045] A method for repairing deep formation CO 2 The method for preparing the leaked chemical grouting fluid specifically includes the following steps:

[0046] (1) By weight, 5.7 parts of MgCl 2 Mix and stir evenly with 100 parts of water in the container until it is completely dissolved;

[0047] (2) Add 11.7 parts of catalyst NaCl to the solution in step (1) and stir until the particles are completely dissolved to obtain grouting solution A.

[0048] use Na 2 CO 3 Solution to simulate a leaked carbon source:

[0049] (3) 6.4 parts of Na 2 CO 3 Stir evenly with 100 parts of water in a new container until it is completely dissolved;

[0050] (4) Repeat step (1-3) process 5 times, mix the solution obtained in step (2-3) in the container, place the container in a preheated incubator (200°C), and start 5 chemical Response test. The reacted solids were taken out after 1, 2, 3, 5, and 7 hours of reaction respectively, and the content of magnesite was quantitatively analy...

Embodiment 2

[0052] A method for repairing deep formation CO 2 The method for preparing the leaked chemical grouting fluid specifically includes the following steps:

[0053] (1) By weight, 5.7 parts of MgCl 2 Mix and stir evenly with 100 parts of water in the container until it is completely dissolved;

[0054] (2) Add 17.5 parts of catalyst NaCl to the solution in step (1) and stir until the particles are completely dissolved to obtain grouting solution A.

[0055] use Na 2 CO 3 Solution to simulate a leaked carbon source:

[0056] (3) 6.4 parts of Na 2 CO 3 Stir evenly with 100 parts of water in a new container until it is completely dissolved;

[0057] (4) Repeat step (1-3) process 5 times, mix the solution obtained in step (2-3) in the container, place the container in a preheated incubator (200°C), and start 5 chemical Response test. The reacted solids were taken out after 1, 2, 3, 5, and 7 hours of reaction respectively, and the content of magnesite was quantitatively analy...

Embodiment 3

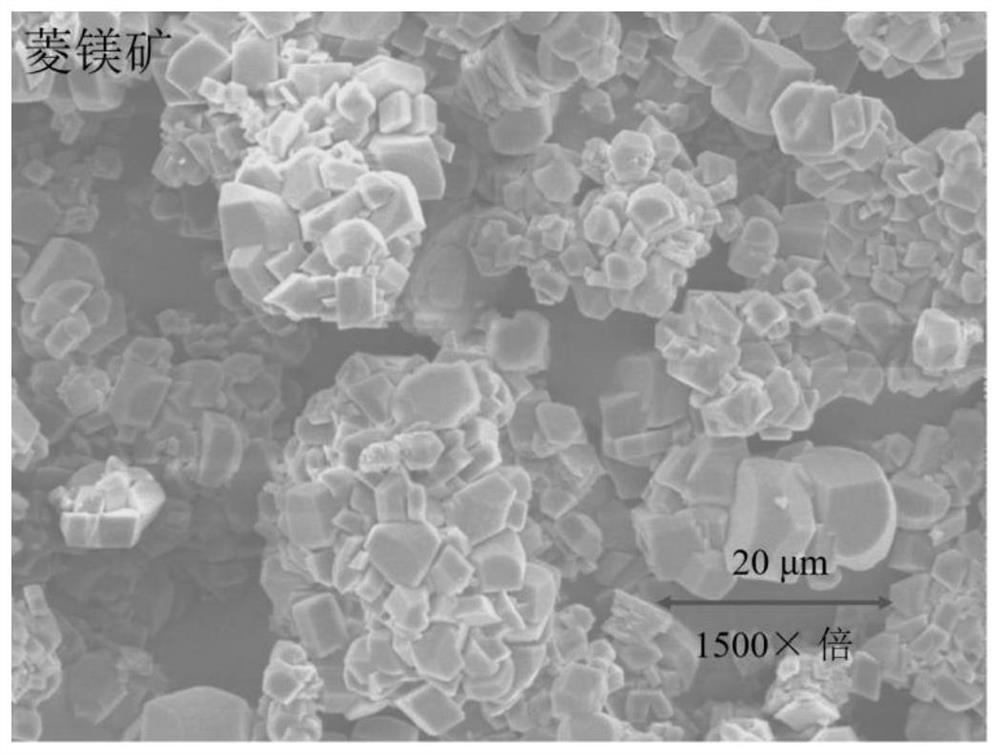

[0059] A method for repairing deep formation CO 2 The method for preparing the leaked chemical grouting fluid specifically includes the following steps:

[0060] (1) By weight, 5.7 parts of MgCl 2 Mix and stir evenly with 100 parts of water in the container until it is completely dissolved;

[0061] (2) Add 23.4 parts of catalyst NaCl to the solution in step (1) and stir until the particles are completely dissolved to obtain grouting solution A.

[0062] use Na 2 CO 3 Solution to simulate a leaked carbon source:

[0063] (3) 6.4 parts of Na 2 CO 3 Stir evenly with 100 parts of water in a new container until it is completely dissolved;

[0064] (4) Repeat step (1-3) process 5 times, mix the solution obtained in step (2-3) in the container, place the container in a preheated incubator (200°C), and start 5 chemical Response test. And after reacting for 1, 2, 3, 5, and 7 hours, the reacted solids were taken out, and the content of magnesite was quantitatively analyzed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com