Manufacturing method of fine-grain high-strength anti-seismic reinforcing steel bar with high tensile-to-yield ratio

A technology for anti-seismic steel bars and production methods, which is applied in metal rolling, temperature control, etc., can solve the problems of difficulty in the popularization and application of high-strength anti-seismic steel bars, reduced strength-to-yield ratio of steel bars, and low tensile strength, etc., to shorten the ferrite phase transformation time, improving the seismic performance of the strength-to-yield ratio, and improving the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, in the embodiment of the present invention, the technical solutions in the embodiments of the present invention will be clearly described, apparent, and is apparent, and the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, those of ordinary skill in the art will belong to the scope of the present invention in the scope of the present invention without making in the pre-creative labor premise.

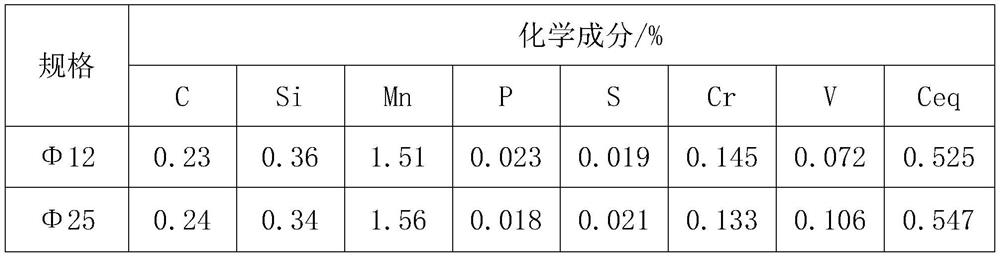

[0023] One embodiment of the present invention is: a high-strength flexible fine-grain high-strength anti-resist steel bar production method, its chemical composition is: according to weight percent, C: 0.22% ~ 0.45%, Si: 0.25% ~ 0.45%, Mn: 1.35% ~ 1.60%, P ≤ 0.030%, s ≤ 0.030%, Cr: 0.12% -0.20%, V: 0.050% ~ 0.120%, the rest is Fe.

[0024] A high-strength flexible fine-grain high-strength seismic steel bar manufacturing method, including the following production steps:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com